Know Your Number

Knowing your quality number or metric becomes the basis of how an organization communicates color as part of a Color Quality Control program. Part of the quality control program identifies a given print reference for the type of work being printed and the goals for production accuracy and consistency, in North America, an industry-standard target is GRACoL and for Europe, the industry standard is commonly Fogra. Defining the target defines the goal for the printing device and the beginning of the communication across department and organizational boundaries. The metric is to determine the acceptable amount of shift in color results. The scientific basis of this is Delta E or E-Factor which are well supported scientifically and in practice.

The metrics used are based on a scale where the lower the number, the better the visual match to the defined reference target; and the higher the number, the greater the perceived shift in color.

To get started, you will want to assess your current production success with ChromaChecker to begin to understand what number your existing work is meeting. Once you know this it will allow for expectations to be tied directly to the printed result and allow production maintenance to be performed at the right time by the right staff.

|

|

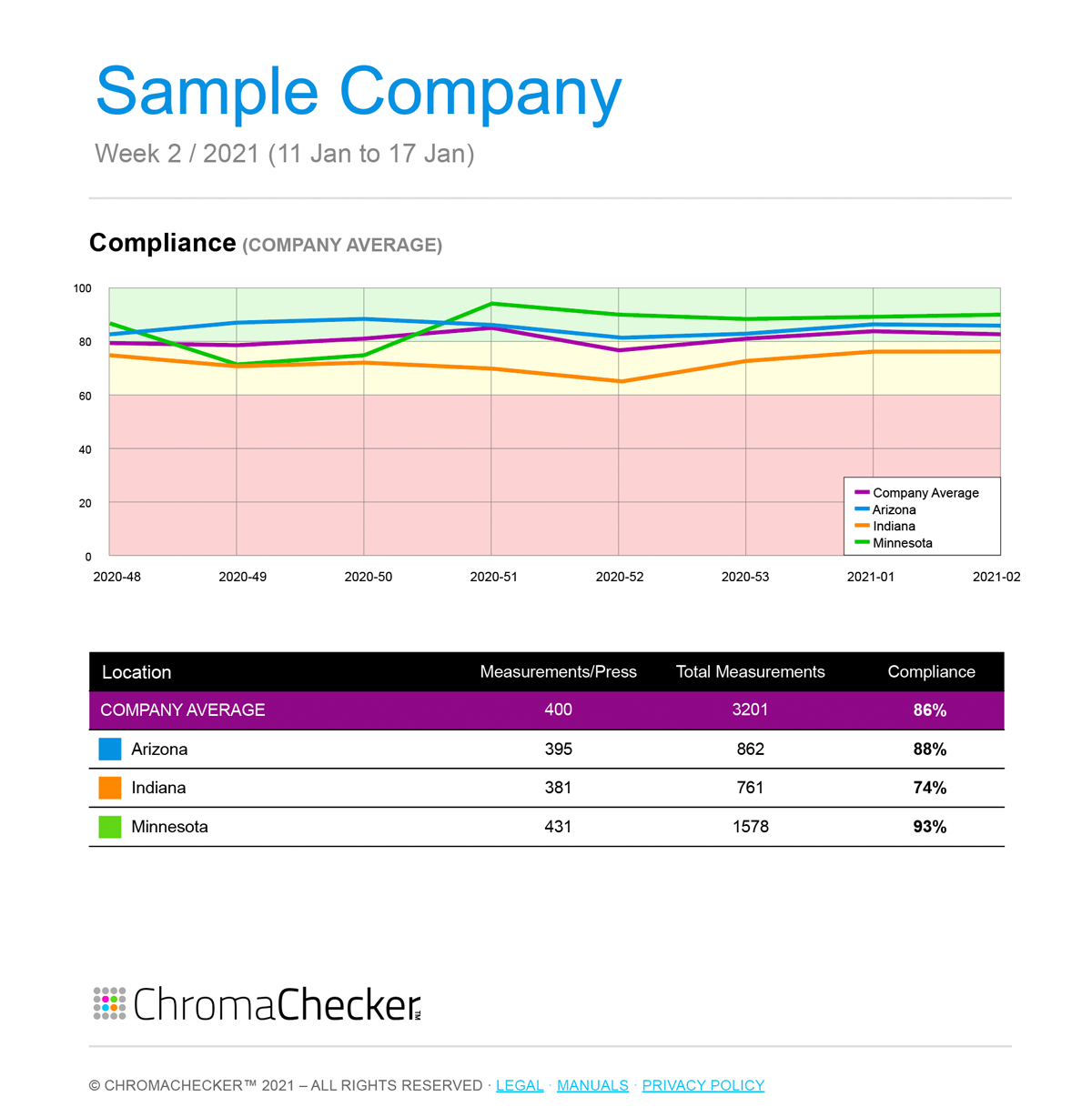

Communicating consistency of color print quality can be completed with Green for within tolerance and with Red for outside of tolerance. This enables all the staff involved to be alerted that something has changed requiring intervention. Starting with the production staff first completing known basic maintenance tasks that will resolve device issues and escalate more complex errors in manufacturing print.

Executives and managers can monitor the Key Performance Indicators (KPI) report providing a window to the overall production metric for success. Performance reports are provided for Top Management, Location Managers, and Production Managers for salability, compliance, and productivity. While operators are provided real-time results, they also can be provided a report showing their performance as compared to the organizational goals.

Having a number at any given time provides insight into the "current state'' and, in turn, provides the basis for decisions. What exists today is the range of capabilities available to drive your business and highlights the capabilities of instrumentation, printers, and manufacturing processes. Knowing what your organization is capable of today allows for organizational planning that will affect all aspects of the business and provides insight into developing a roadmap for success.

Providing data measurements can also become the basis for decisions related to purchasing, allowing for past investments such as instrumentation and printers to have a new life while defining requirements for future purchasing decisions.

The six assessments that can be evaluated before purchase include:

- Color Gamut — We are determining the gamut size by calculating the ISO Gamut size in a numeric number, and we are calculating the percentage of PMS colors that can be reproduced within 2 delta. This test assesses the device/ink combination.

- Uniformity — Within Page uniformity to determine the degree of uniformity on the imaging area.

- Reproducibility- Between days to determine the uniformity and repeatability benchmark of the press over time.

- Repeatability — This assessment reports the between page variation

- Addressability — This assessment compares the resolution and contrast of the capabilities of a device.

- Color Accuracy — This assessment is defined as a preferred print aim target and directly relates to the workflow and substrate used for the benchmark.

When it comes to COLOR — It’s clear that things have changed -- now is the time to relax what you know about your color production and MEASURE what is being produced and how it is being COMMUNICATED.

Once your number is established, the planning for improvement becomes clear, past investments in instrumentation, printing presses, and manufacturing processes can be evaluated, while future investments can be targeted at measurable improvements while progress is reported to evaluate the value of those changes.

ChromaChecker allows you to report on a real-time basis and empower management to make informed decisions regarding investments and organizational goals. This will allow you to quantify your color consistency for precision and accuracy, provide reports, set appropriate goals, and monitor performance using KPI reports.

Video

-

The starter kit provides the target and white/black backing for ensuring the instrumentation is ISO compliant and the environment is within manufactures specifications. Also included in the kit is an E-Factor printed exercise for establishing an appropriate tolerance for acceptable color shift for your production environment.

-

This tutorial shows how to work with the Image Exercise to set color match expectations. E-Factor is used to evaluate process colors and the amount of color shift from one sample to another. This uses the Cumulative Relative Frequency of the 95th percentile Delta E.

-

ChromaChecker is a powerful system to enable color communication across an organization as well as crossing over organizational boundaries. By setting goals and providing the tools to maintain consistent color you can ensure is salable while eliminating waste.

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.