Liquids

Does the Color of Your Product Matter?

In this real life scenario, we were at the store and restocking our Bai beverage of choice when we encountered this dilemma: which Lemonade was the right one.

At first we thought they were two different flavors, but upon closer inspection, they were the same! Then we asked one another, "Do you think they will taste the same?" No!! Well which one is right, and will I get sick if I drink the one that is wrong? And even though we have bought this product in the past, we did not remember which one was the "normal" color. Any loyalty to this brand was instantly lost because we couldn't trust which product was right.

Ideally, the Bai brand should implement quality control for color at the manufacturing facilities so this type of thing will never happen again... This article will provide an inexpensive and effective way to implement quantify control for color and set color standards to make sure this never happens again.

ChromaChecker is a Cloud based Color Conformance Platform that brand companies purchase to ensure that all color critical manufacturing is matching standards on any product and package manufactured any where in the world.

Below are three steps to get your quality color conformance set up and implemented with your manufacturing groups. This case study focuses on measuring liquids, but the process if very similar no matter the form of the physical object that the brand want to control (plastic, fabric, packaging, etc.).

1. Select the right Instrumentation and methodology

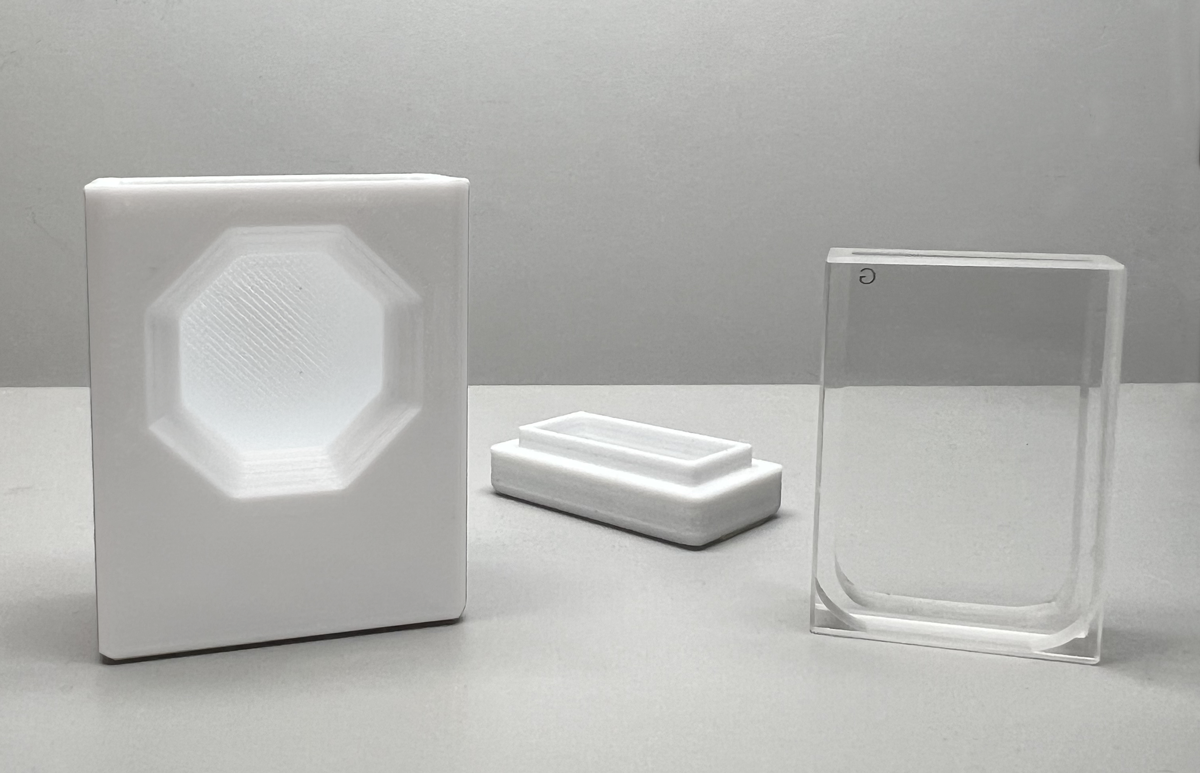

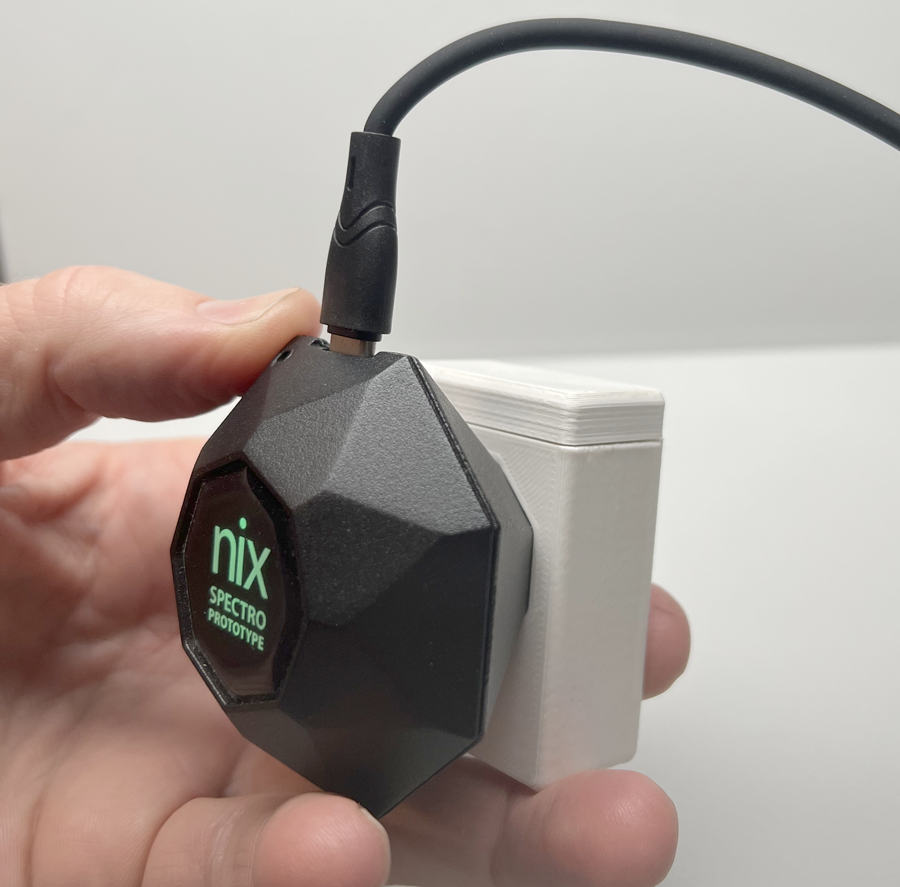

ChromaChecker Capture supports more than 10 color measurement instruments. One of them – NIX has an optional adapter that enables liquid to be measured and quantified. It is a glass container which is placed inside a plastic adapter with white background and cut out to position the NIX Spectro 1.

2. Calibrate the instrument

Regular reflectance measurements require ceramic tile for calibration. In the case of the glass container, it is critical to recalibrate the instrument. That means we need to "teach" the instrument what white is. For the liquids white – means fully transparent liquid, for lemonade we can use fresh water. You will not want to calibrate using an empty container because you need similar optical conditions to the actual production measurements.

Notes:

- Make sure the white calibration background is clean

- If your liquid has fractions, shake it beforehand, but be careful if shaking causes bubbles

- Some liquids (e.g. beer) cannot be shaken - in this case, filling the container by pouring over the glass rod will help to avoid foam

- Use a microfiber cloth to dry the outer surfaces of the glass container

- Check visually whether unnecessary artifacts have been introduced into the measurement field

- Use the same container for calibration and all production samples, do not mix containers.

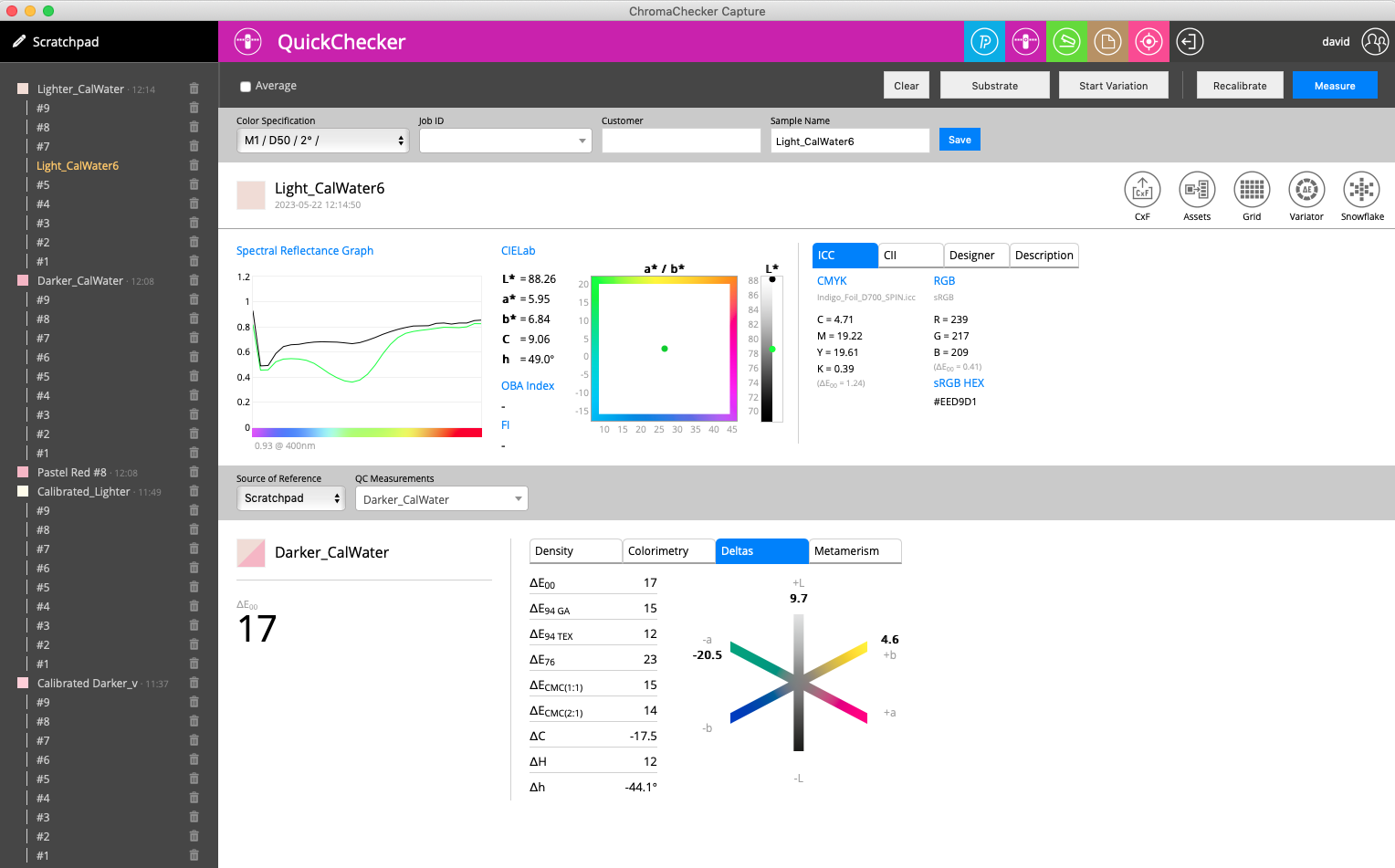

3. Launch CC Capture into QuickChecker tool

The easiest way to compare samples is to measure the first one, then define it as a reference for all subsequent measurements. Once the second measurement is done we can see all important differences including all kinds of deltas. Additionally, we can see a spectral curve comparison that helps us to understand how the color is different. We can also print Pass Fail labels to document the manufacturing is within defined color expectations.

In this example, the difference is ∆E00 = 17, but the biggest difference is in ∆b > 20.

Conclusion

NIX Spectro when driven by CC Capture makes it fast and easy to establish reference color values for any type of product, and packaging to compare production values against, and understand if they are within the brand's level of expectations for a color match. No matter the subject matter, ChromaChecker can compare differences, and document all spectral and colorimetric values.

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.