Named (spot) colors strategies

Please note that all following guidelines are successful only for in-gamut color. Make sure that the named (spot) color can be reproduced. Use the Virtual Spot Print function for initial prediction.

If you are using the Color Match function, you already know it.

The key is understanding the problem of printing named (spot) colors.

The users have very different hardware/software combinations.

Photographers | Designers | Small print shops.

We know printers are rastering all using Adobe Photoshop and printing based on hi-precision RGB profiles and process Print function built into Photoshop. That solution is not very practical for high-volume production, but it offers the best precision and control of color reproduction for some premium jobs. Photographers and designers mainly use this method. It doesn't need expensive RIP, but for accuracy, a spectrophotometer capable of building a profile is required.

In this method, the operator should understand color management - especially the difference between convert and assign. Also, differences between rendering intents are critical.

Small /medium size print shops

Often, your printer can print a wide gamut, but it is narrowed down to common color space like GRACoL (US) or ISO_Coated_v2 (EU). Such a solution requires a more straightforward configuration and is finally "safe," which means processing untagged files will not unnaturally enhance saturation.

The disadvantage of GRACoL or other standard profile simulations is that we often lose the gamut for spot ( named) colors. That will not happen when the RIP offers LUT—Look Up Tables for spot colors.

There are many solutions on the market, and the user must learn which options are available for a particular workflow.

Steps for selecting the best method

- Learn about your hardware configuration. Is your printer driver directly by the operating system, or is dedicated RIP used to control the printing process? Is your solution based on the RGB or CMYK profile?

- Examine your substrate for OBAs and your Lighting Condition for the UV components.

- Find ICC profiles that describe your printing condition—it might be a custom-generated device profile, typical media profile, or standard simulation profile. Please understand that only custom ICC profiles can be accurate.

- Test the selected method. Check if you have control over your workflow. You probably need software like Adobe Acrobat or a spectrophotometer.

- Save all configurations and create screenshots from the basic settings so it would be easy to recall them anytime. Ideally, create an SOP.

Acrobat Output Preview — extremely helpful tool!

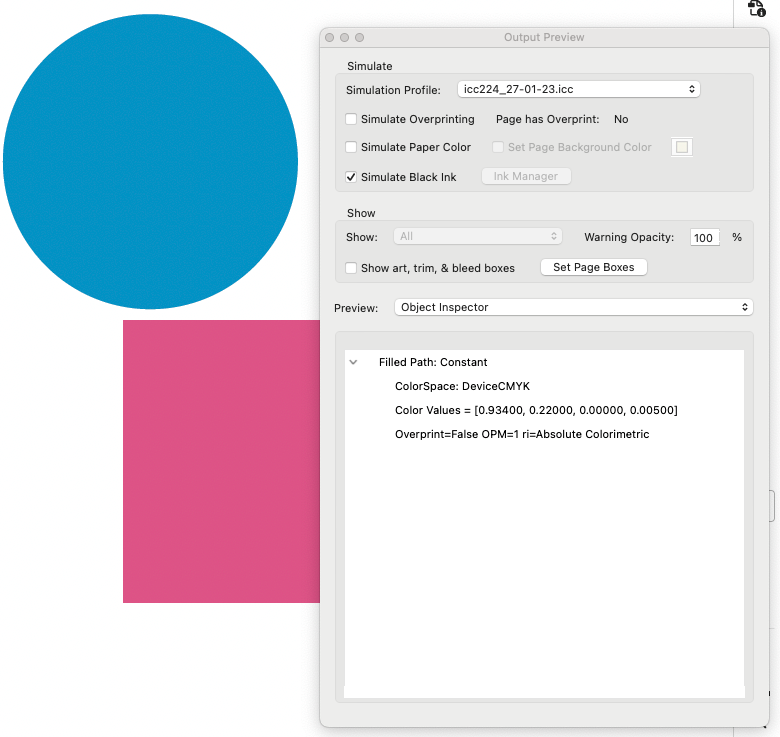

It is very important to have a reliable tool that can examine the color of any object in a PDF.

- Adobe Acrobat with Print Production tools gives such a possibility, and this tool is highly accurate.

- Open the PDF file; in All tool, find " Use print production," next select "Output preview."

- Change Preview from "Separation" to " Object Inspector" and select any object to read how this object is defined.

Color Space Device CMYK, Color Values in this example: 0.93400 —> C = 93.400%, 0,.22000 —> M=22.000%...

It is essential to check your workflow. Various settings can modify color coordinates: rendering intent, version of Adobe PDF file, color settings of your application, and more factors—all can make unexpected changes.

1. Photoshop direct printing feature.

It might be good to have this method ready for solving issues and as a redundant solution. It also helps to learn the principles of color management and the consequences of selecting various parameters (e.g., rendering intent). We recommend checking this method even if the basic production workflow is different.

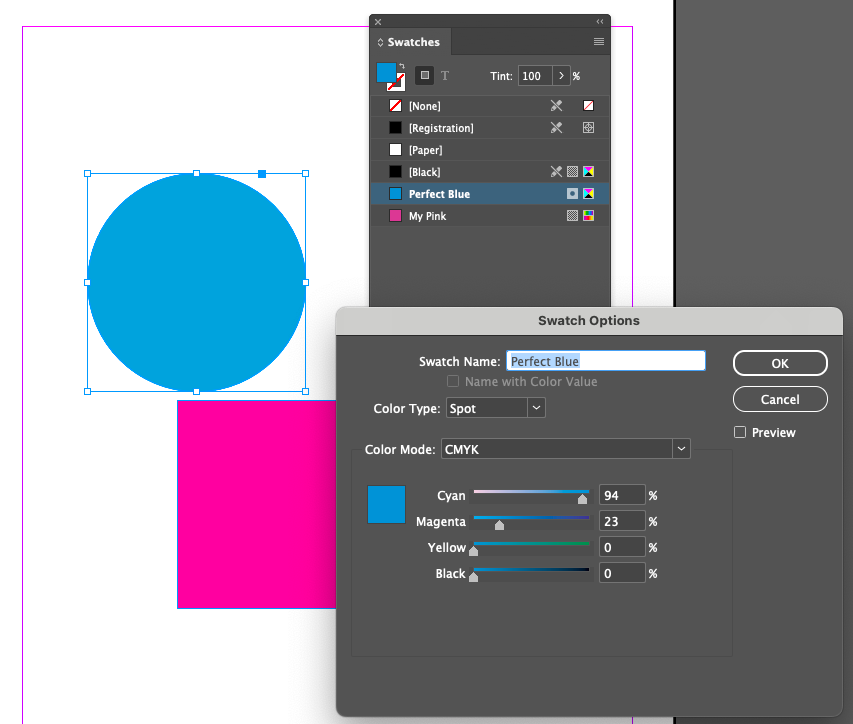

2. Redefine color in native graphic design software (InDesign, Illustrator)

If you can access the source file, editing the color definition is the easiest way.

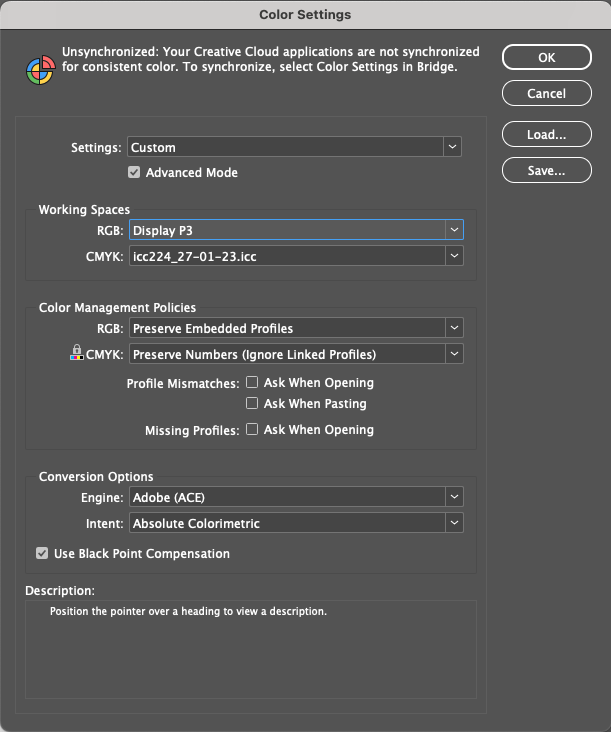

Be sure that the proper ICC profile is assigned as a Working Space in Color Setting (InDesign)

The selected ICC profile should be identical to the one for Color Match. In this example, it is

Change Spot color to Process - use corrected values from Color Match.

Color Type selected: Spot —> change it to Process

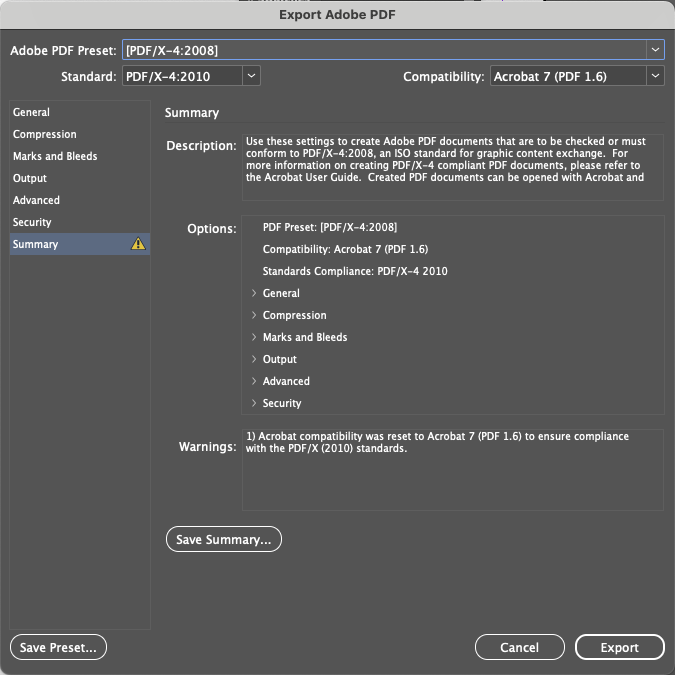

Be sure to set the Export properly - for example:

It is important to recognize PFDF standards and other expert settings - if not familiar, the best approach is to experiment.

Use print production (Adobe Acrobat) to check the final color coordinates of critical named colors.

3. Open and edit the PDF in Illustrator

When editing files, select all color settings in a controlled way, and be careful what PDF standard is selected.

Use print production (Adobe Acrobat) to check the final color coordinates of critical named colors.

4 . Upload LUTs to RIP

This is the most advanced method to manage named colors. The same file can be processed differently on various printing devices, but this method requires workflow to make it possible. Most Color Engines can support LUTs, but some RIPs may have limitations. The different print conditions typically require separate ICC profiles and workflows in the RIP/ Color Engine environment.

What is the problem?

Often, your printer can print a wide gamut, but it is narrowed down to common color space like GRACoL (US) or ISO_Coated_v2 (EU). Such a solution requires a more straightforward configuration and is finally "safe," which means processing untagged files will not unnaturally enhance saturation.

The disadvantage of GRACoL or other standard profile simulations is that we often lose the gamut for spot ( named) colors. That will not happen when the RIP offers LUT—Look Up Tables for spot colors.

There are a lot of solutions on the market, and the user must learn which are available options for a particular workflow.

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.