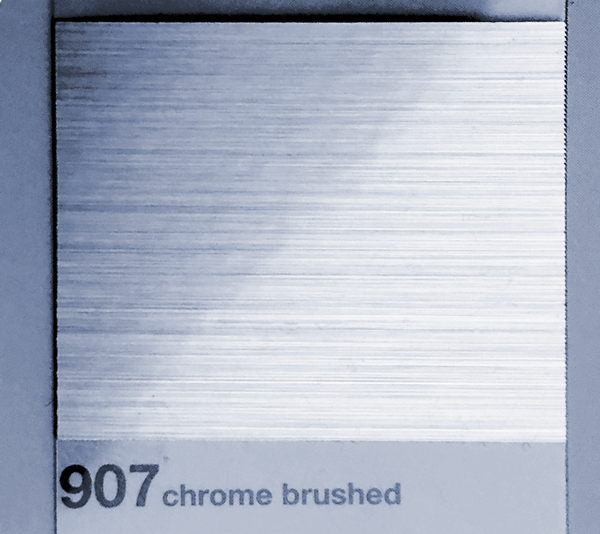

Unusual Measurement surfaces- Polyester Film - Chrome Brushed 907 - ORACAL® 352

The specimen comes from ORACAL 352 - This is an example of polymeric cast film with a three-dimensional visionary texture. This is offered as a substrate with excellent dimensional stability and good long-term aging properties. It has a top coat ready for printing (UV- offset, LFP, silkscreen).

The selected film has a brushed effect, and scratches are unidirectional. This is important, as it influences measurement results. What do we expect from the measurements? Is the chrome metallic surface white? Grey? In this case, it is not glossy - a brushed surface makes it closer to the matte, but when we change angles of observation and illumination, the material reacts, and end measurement result matters because of the change.

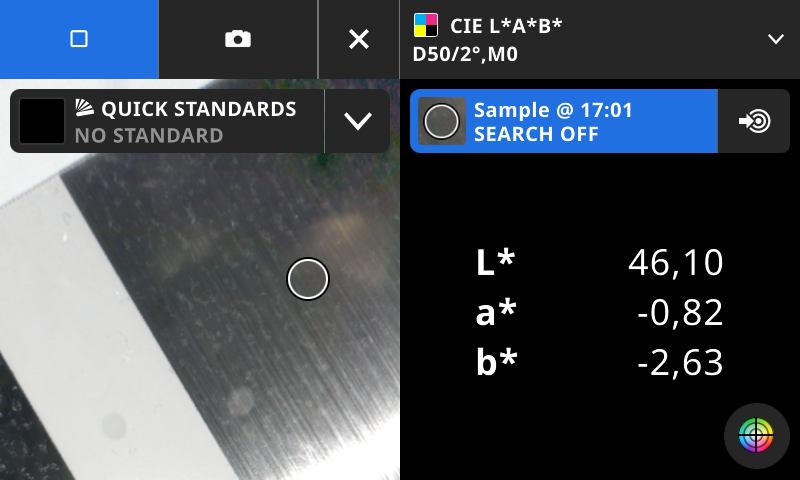

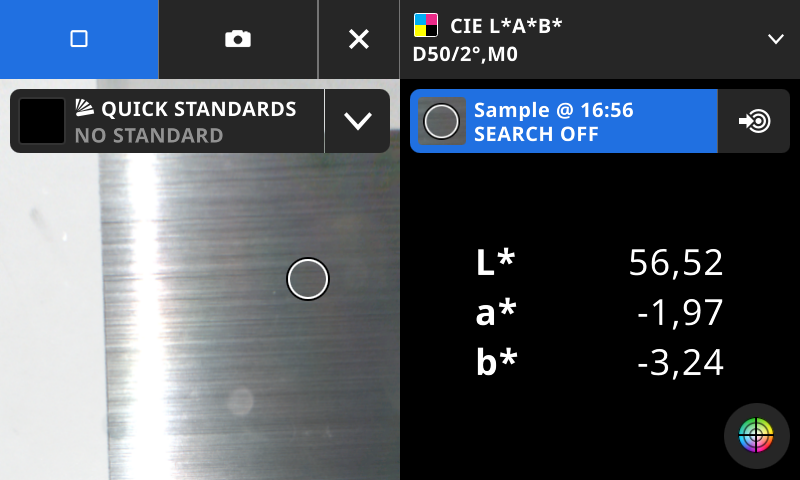

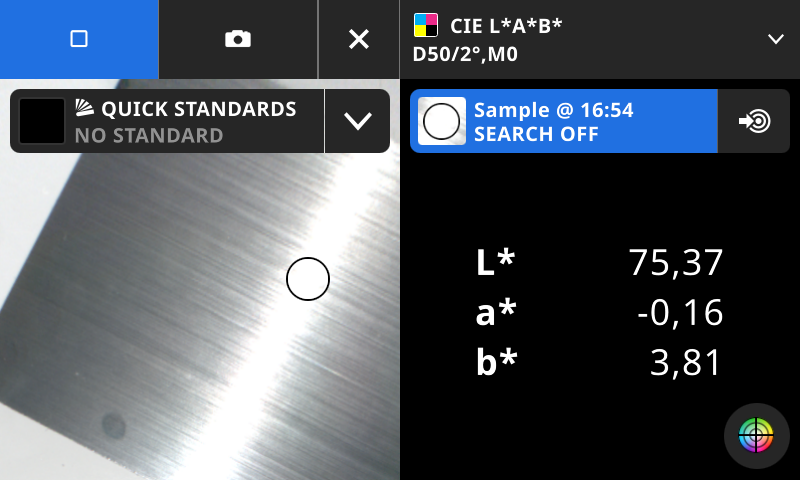

X-Rite eXact 2

M0

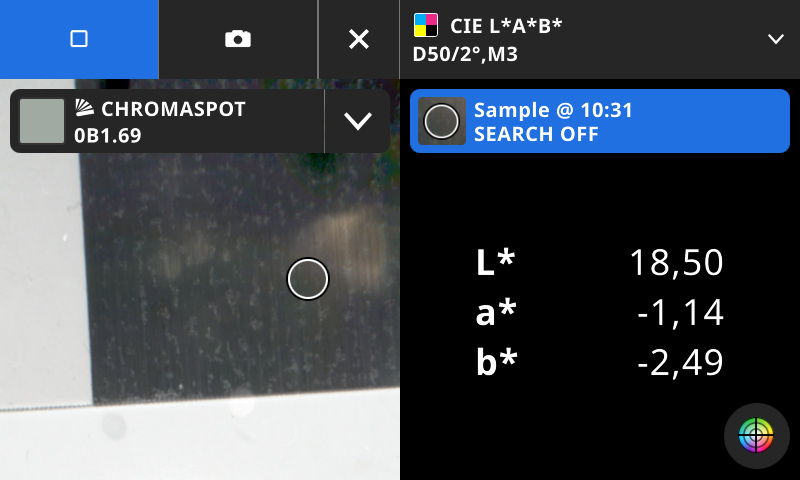

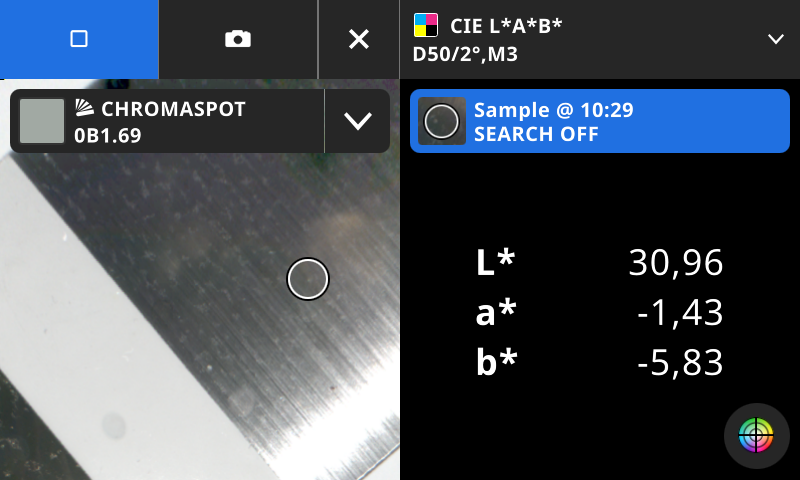

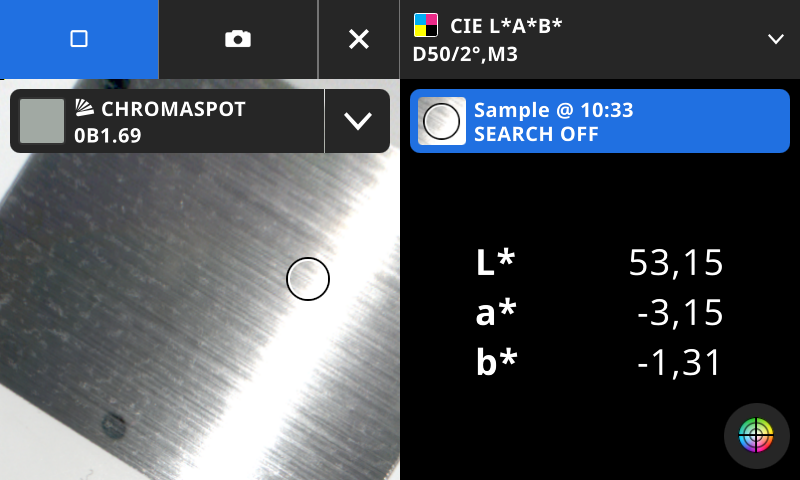

M3

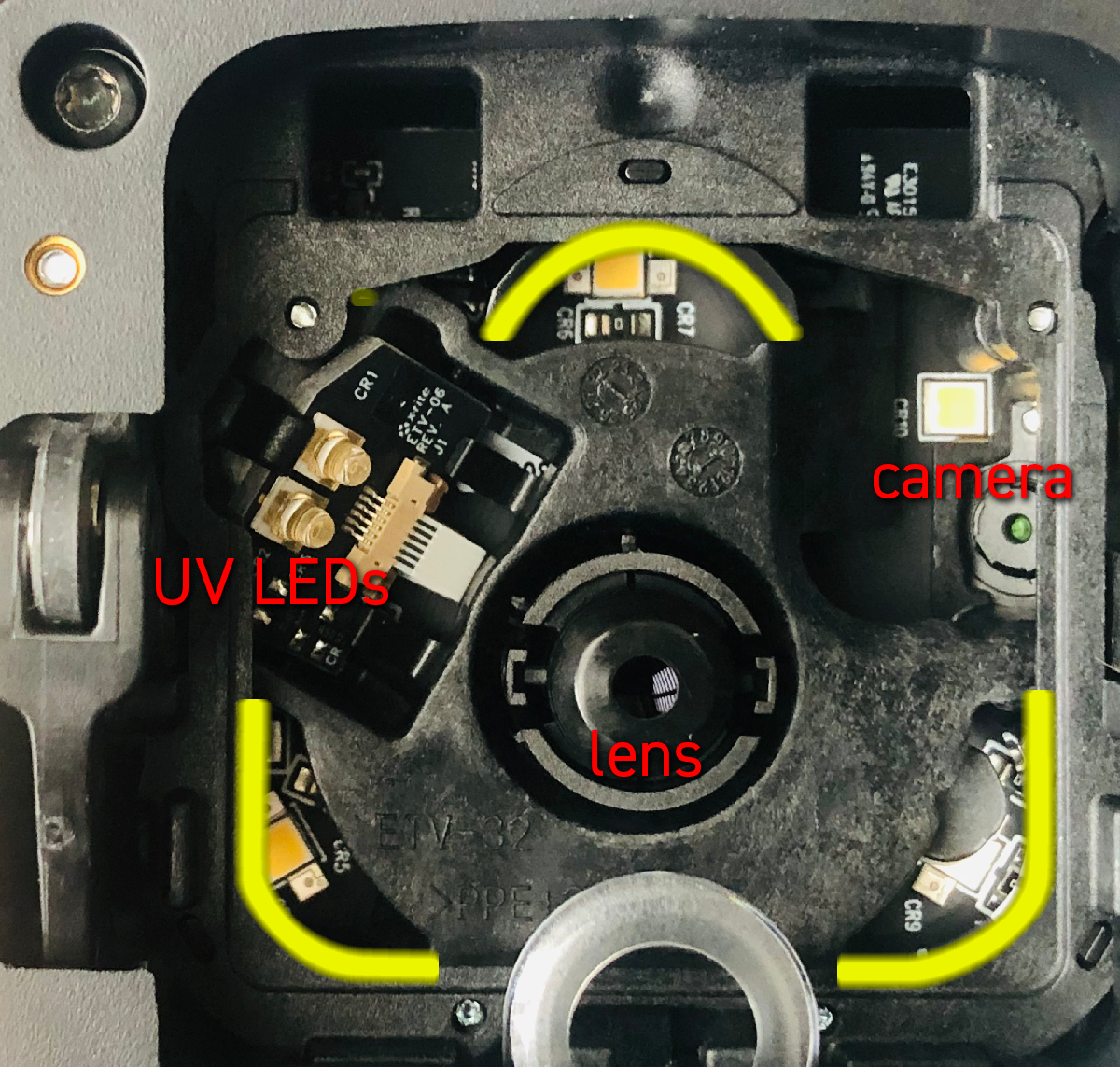

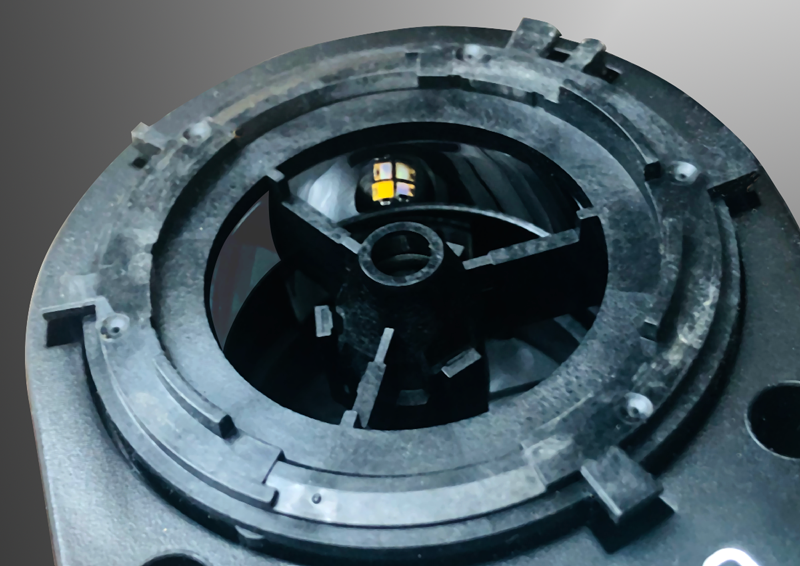

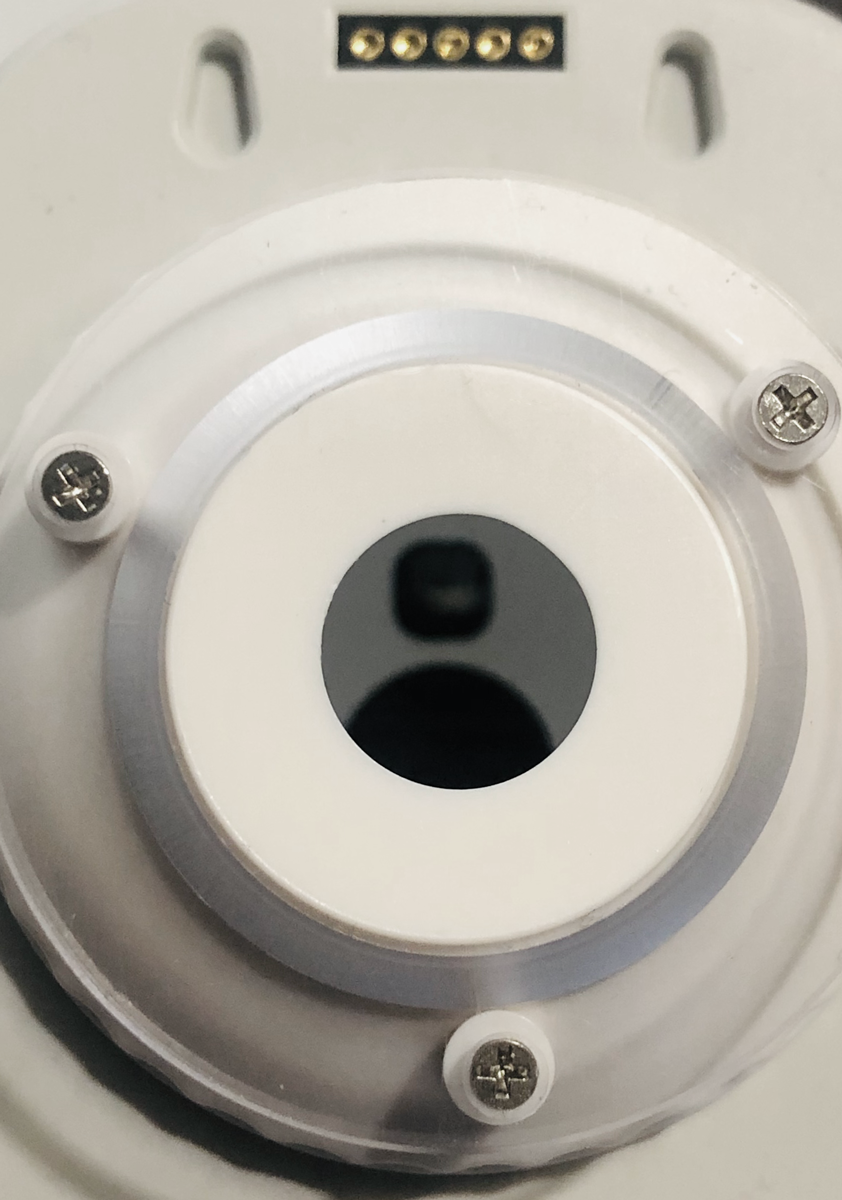

Please note that the internal camera's pictures use a different light source! Visible reflections come from a single camera-dedicated LED, while spectral measurement uses a sophisticated system of curved mirrors.

|

In this case, the complexity of instrument design is a compromise where segments of the ring light the sample. In the picture, we can see a camera with a dedicated LED. |

|

The complex shape of curved mirrors finally produces illuminating ring (annular 0/45 geometry) thanks to brilliant engineering. The only UV comes from a single direction - but this is precisely what is in the instrument specification. |

State-of-art eXact 2 is NOT designed for metallic surfaces - it can't be used for this sample.

L value changes from 46 to 75 for M0 and 18 to 53 for M3, which is expected.

X-Rite i1Pro 3

In this example, the variations are significantly reduced due to the different constructions.

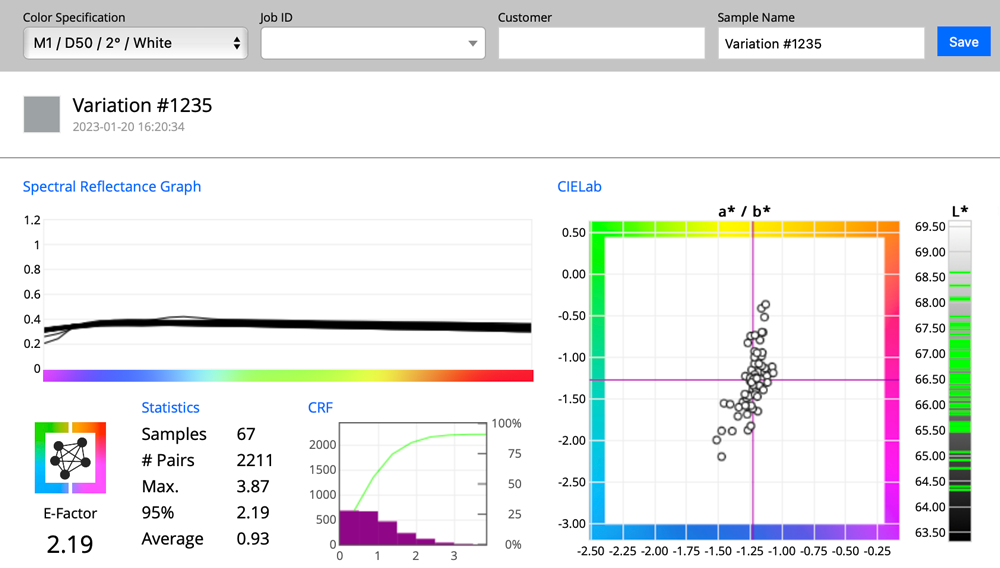

In this example, the L has values between 65 and 68 - Variation E-factor = 2.2 (means about 1.1 from the average)

The problem is Grey where L=66.5 is how we see it.

|

Understand the i1Pro3 better! X-Rite i1pro3 has a curved mirror with an almost perfect annular geometry (only three very thin braces interrupt the continuous ring) - and that's one of the reasons why i1pro 3 measures so well. Four different LEDs are mounted in the very center, but direct light is eliminated, and only 45 annular are used. |

Of course, this function alone doesn't mean i1Pro3 is better than eXact 2 - but in this particular case study, the i1Pro3 produces a much more repeatable result.

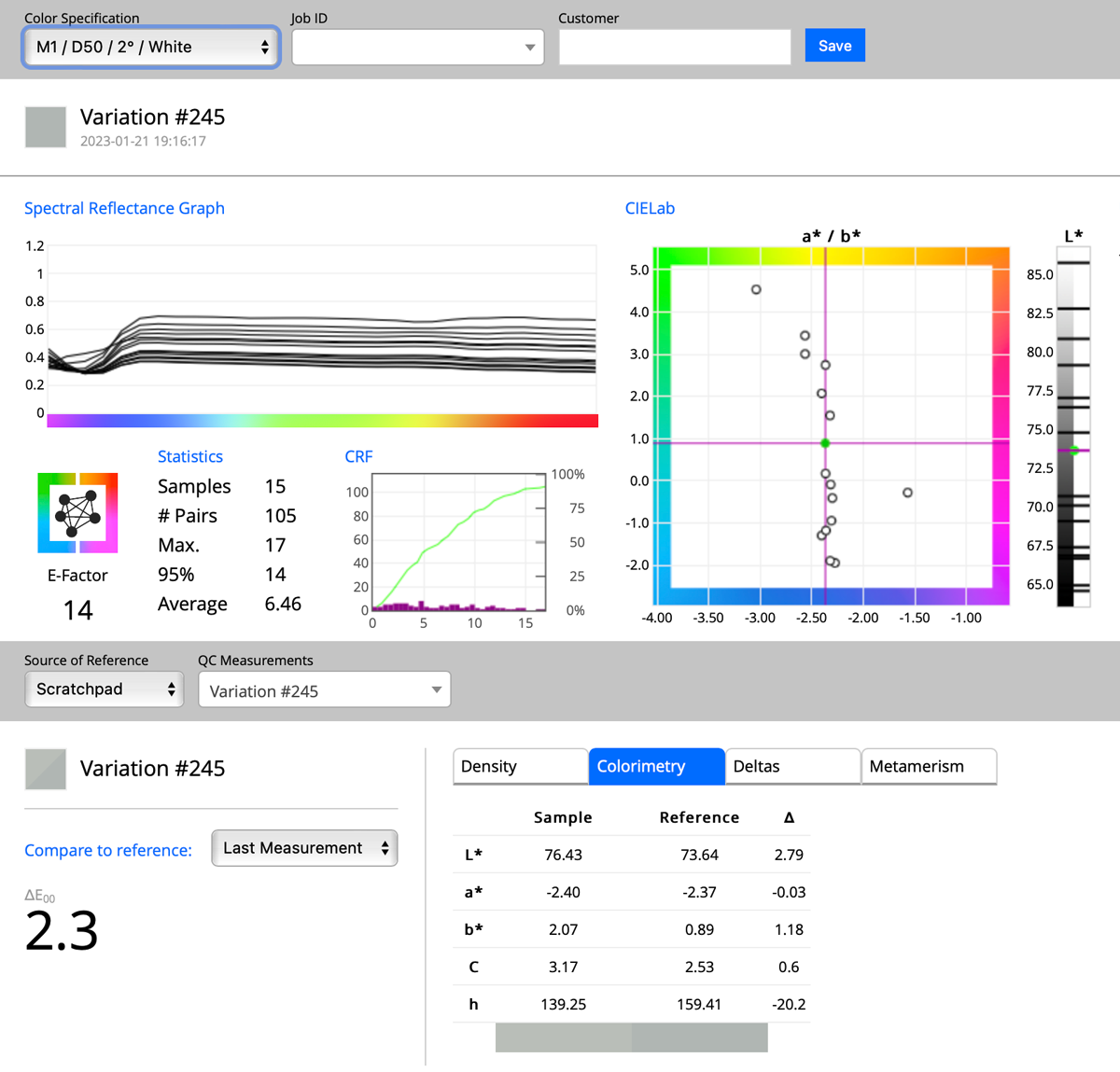

Nix Spectro 2

This instrument has an illuminating ring of LEDs, made up of different kinds of LED; which results in the spectrum being well controlled. This instrument is sensitive to rotation errors on non-uniformly reflecting objects like the ones used in this test.

Variable Spectro 1 (D/0° Geometry) SPEX

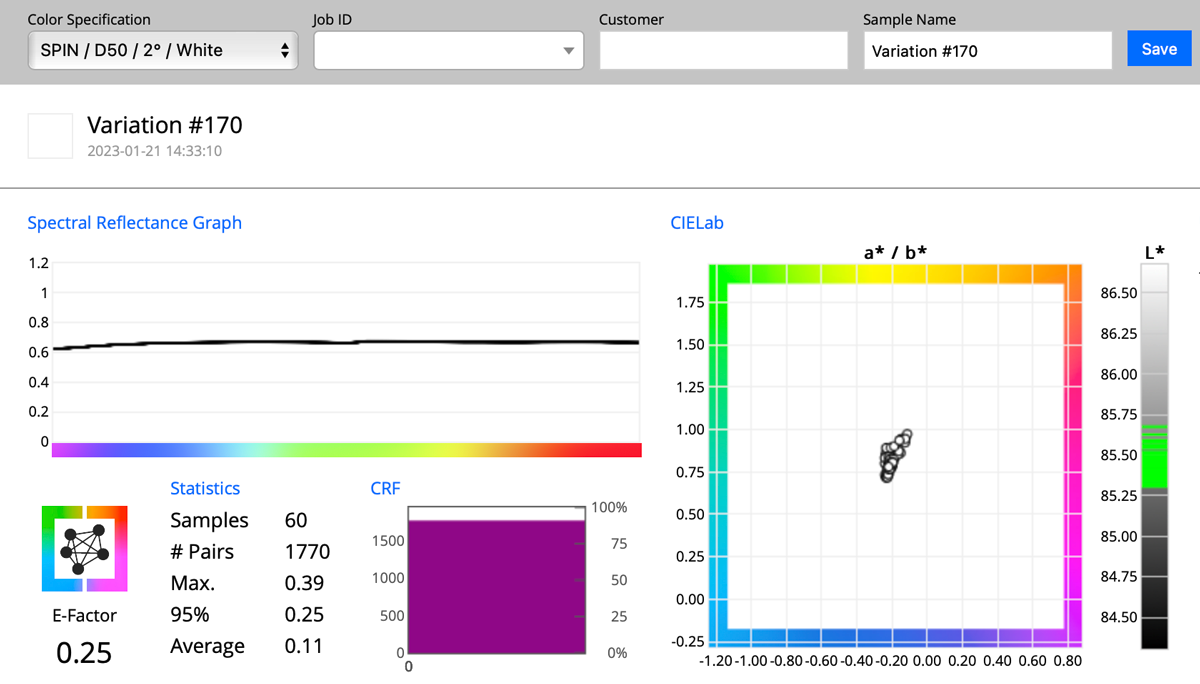

Variable Spectro 1 PRO (D/0° Geometry) SPIN

DS-700D (D/8° Geometry)

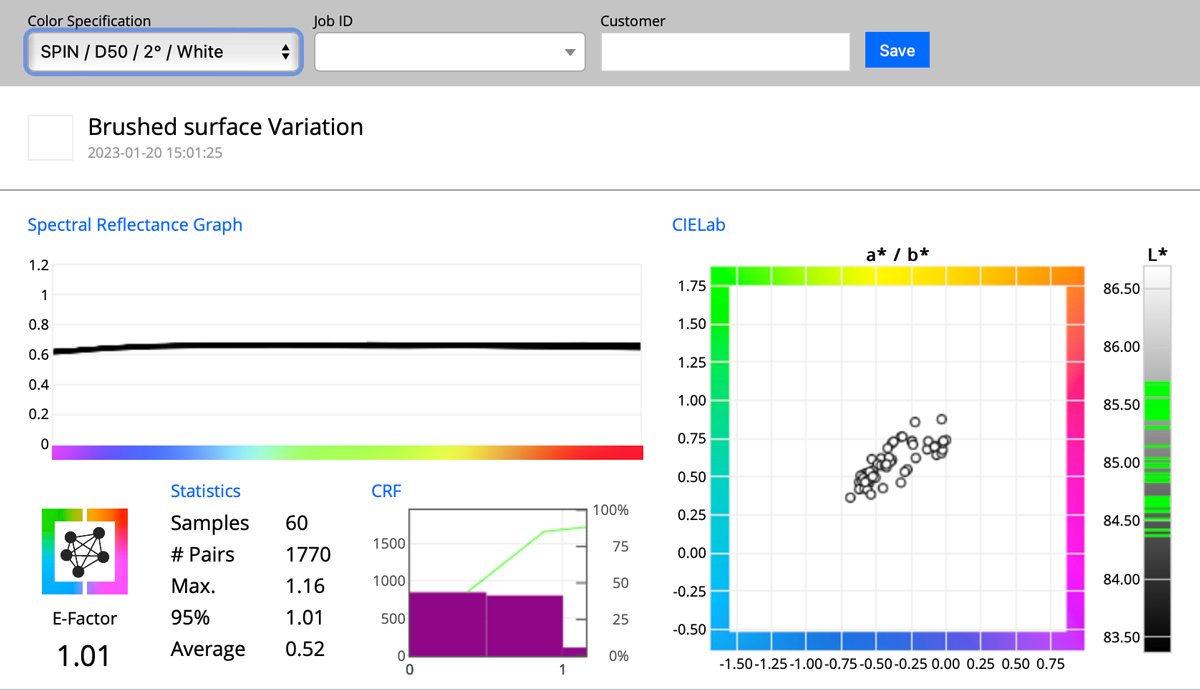

SPIN

Specular Included Measurement average has L= 85

That is metallic silver with scratches that reduces white to light gray, and where there is no black trap, it is very in line with the human eye, where the sample reflects (as all metallic surfaces) white walls or ceiling.

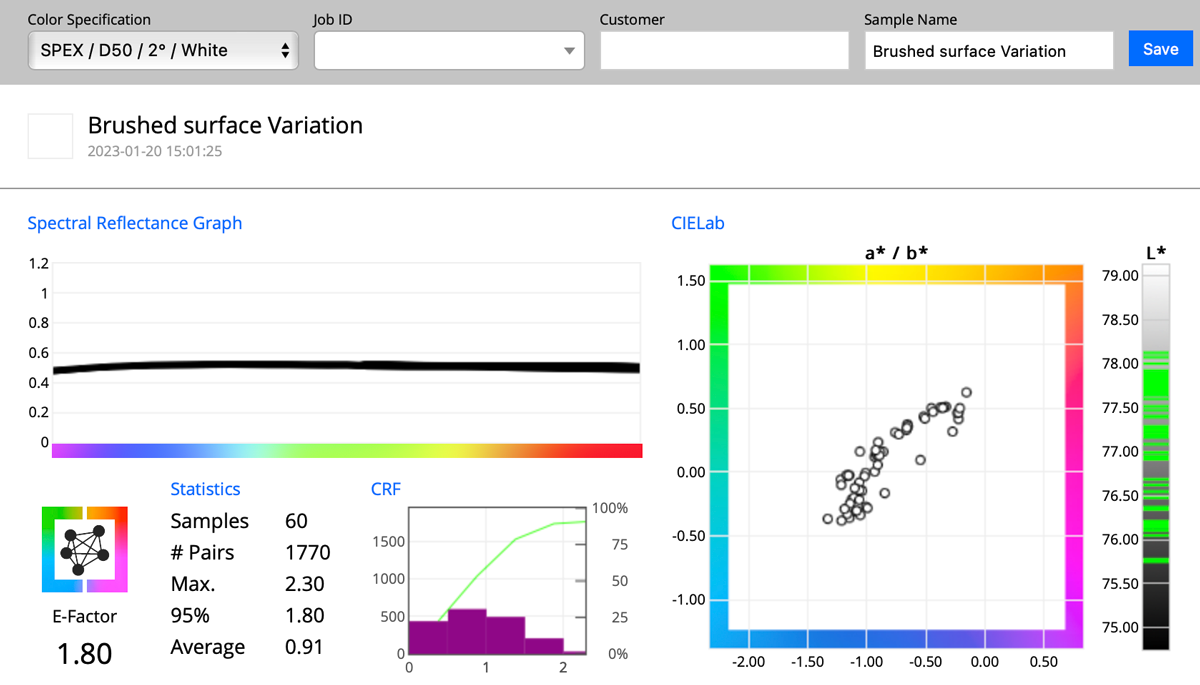

SPEX

Black Trap reduces the human impression that equivalent grey is darker - but due to brushed texture not to L= 77

Is this instrument perfect for this kind of sample?

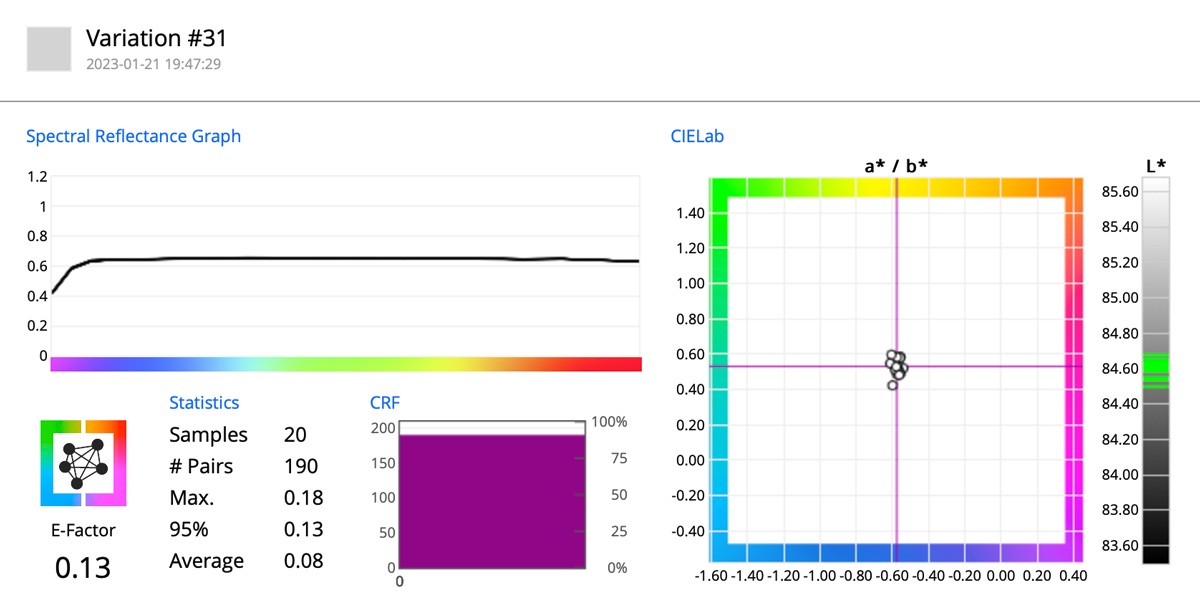

We did a complete evaluation of how the surface direction of brushing impacts the results, and there is a regularity that makes variations on a noticeable level with average variations: for SPIN = 0. 52 (±0.26) and 0.91 (±0.455) for SPEX.

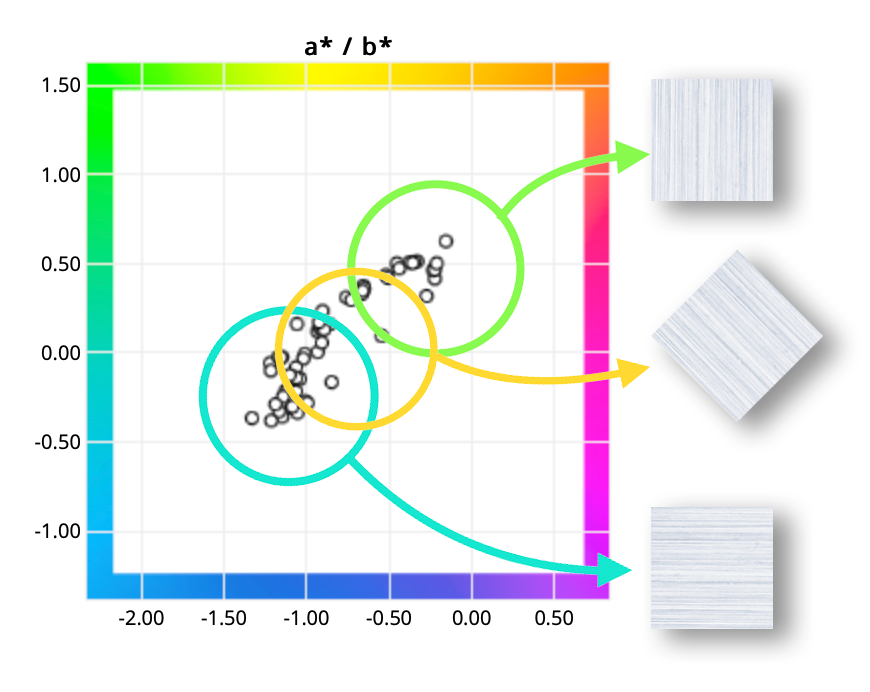

D/8° geometry has one direction where the sensor is located - the unidirectional texture changes sensor readings

|

Spread of measurements relay on specimen direction. Most "vertical measurements are more reddish while horizontal rather blueish. |  |

We can see the sensor window and internal trap through the aperture. Brushed specimen reflects differently depending on the angle. |

The accuracy of the measurement procedure can be improved when the angle is defined and constant. This requires that the operator takes care to ensuring the sample is positioned relative to the instrument in a consistent manner. This instrument has a built-in camera, and the Operator can use it to ensure they are doing it consistently.

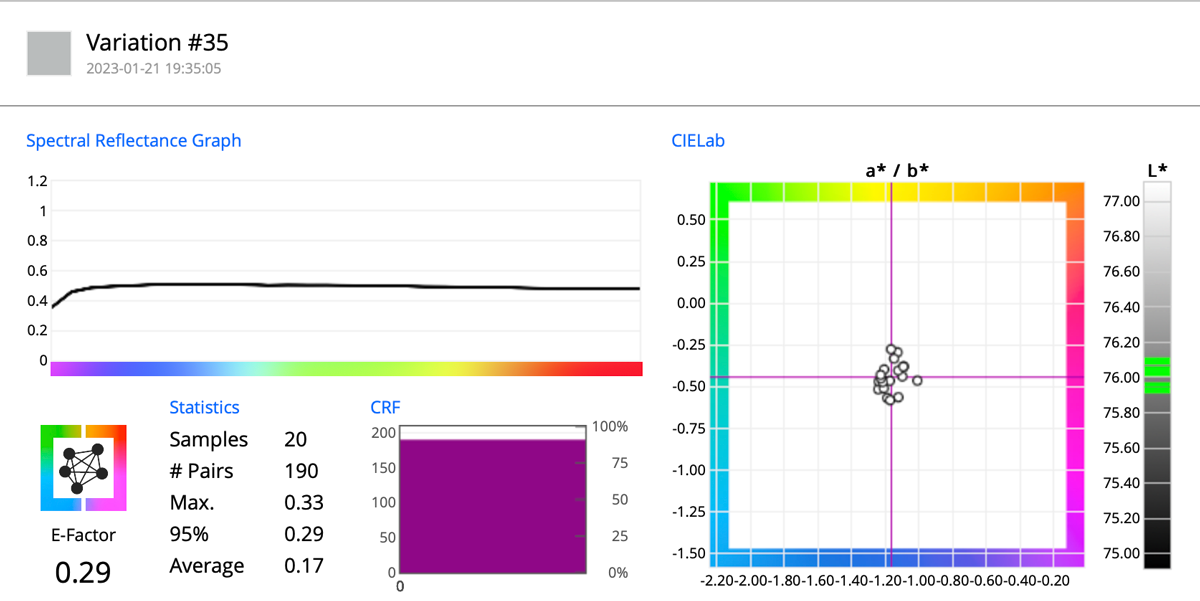

The same test with displacement but using a single angle!

In this test, 60 measurements with instrument relocation on the sample were taken. Variation average SPIN = 0. 11 (±0.055) is now reduced five times compared to the random-angle scenario.

Conclusions

- Whenever the sample is not flat or texture-less, the surface effects makes it is critical to find the best Instrument and measurement methodology that is reliable and consistent for the given sample.

- None of the instruments on the market can measure all objects perfectly. Having multiple types of instruments is the only solution to cover a wide variety of measurement samples.

- Analyze the variation of the specimen to see what has influenced on final results. Using ChromaChecker's CC Capture unique tool called "Start Variation," perform 20+ measurements (it takes only 1-5 minutes for most instruments!) to understand a new type of sample.

- Check the different types of instruments, and test various scenarios - especially M-conditions to be sure what condition is most relevant to meet your goals.

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.