Instrument Comparisons: Short-term repeatability

Purpose of experiment

Most instrument manufacturers specify short-term repeatability on a White BRCA. No additional data is provided. We have observed that most instruments are fairly stable when measuring on white patch, but less stable when measuring darker patches, which means more variation. This experiment will document what typical within instrument variations are for different instruments on the market. This experiment will use ChromaChecker Capture's Start Variation tool to capture the data.

Why black measurements are less accurate than white measurements?

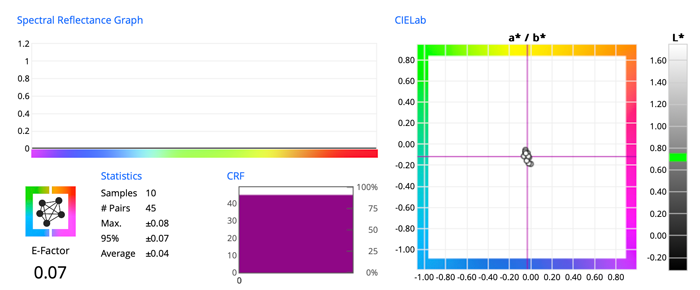

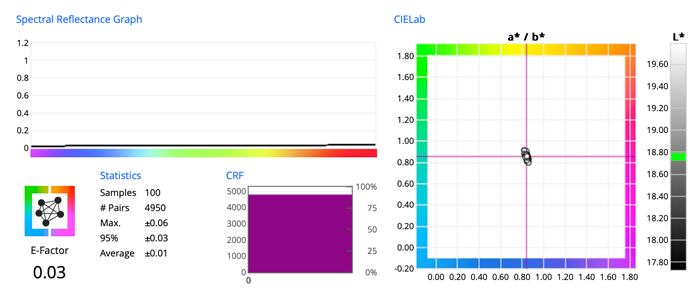

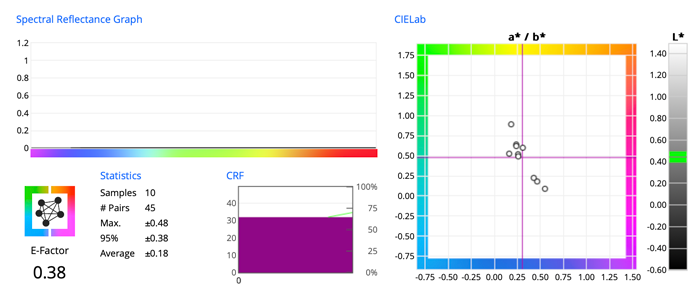

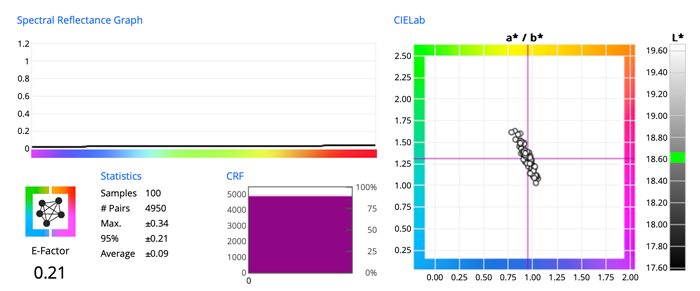

Sensors are electronic devices that convert light to electric signals. The signal-to-noise ratio for black patches is an important factor. Black values when analyzing spectral curves are represented by larger variation numbers compared to white values. Differences are expected, but documenting the differences in delta E and 95th percentile (E-Factor) delta E is very informative.

Experimental conditions

In this experiment, we performed three tests:

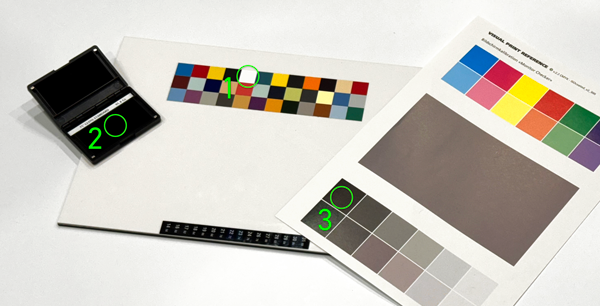

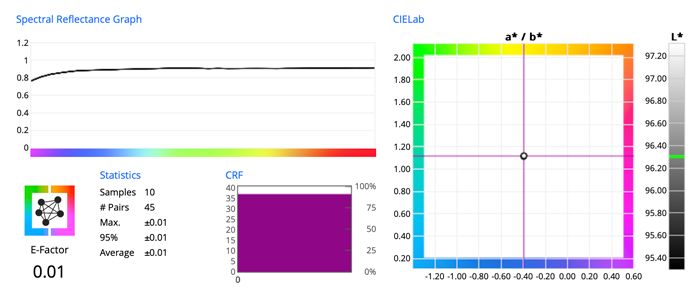

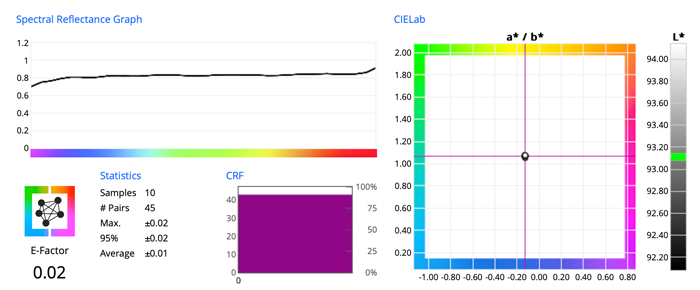

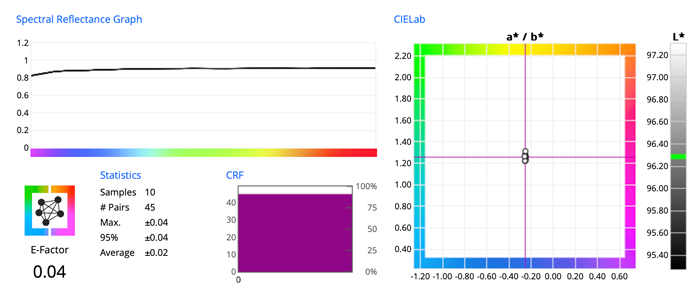

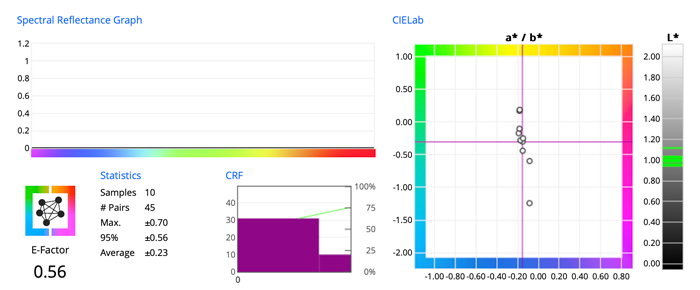

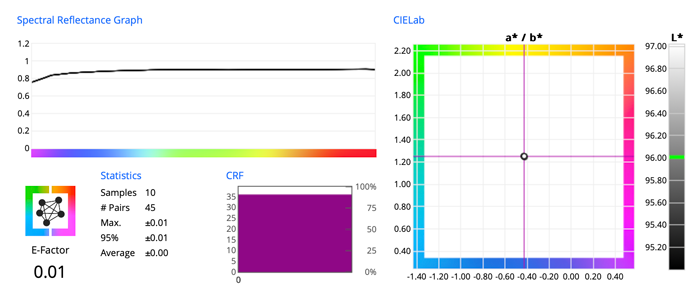

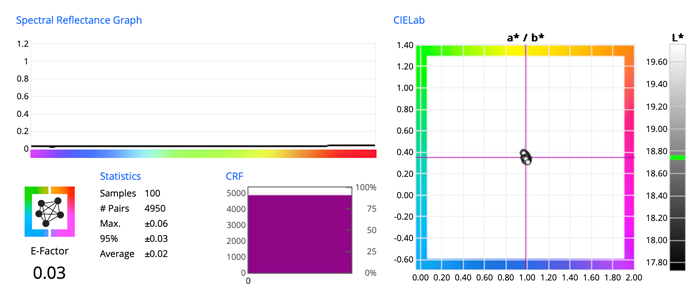

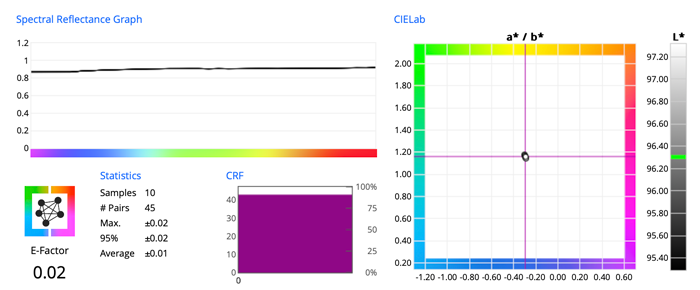

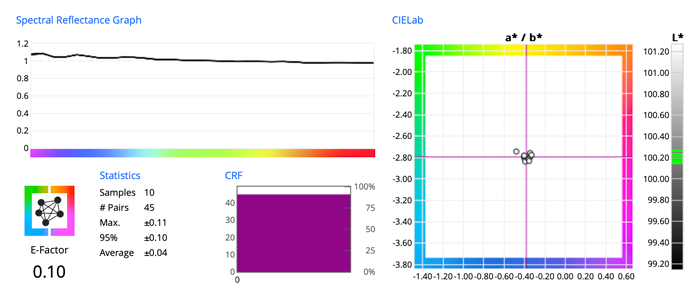

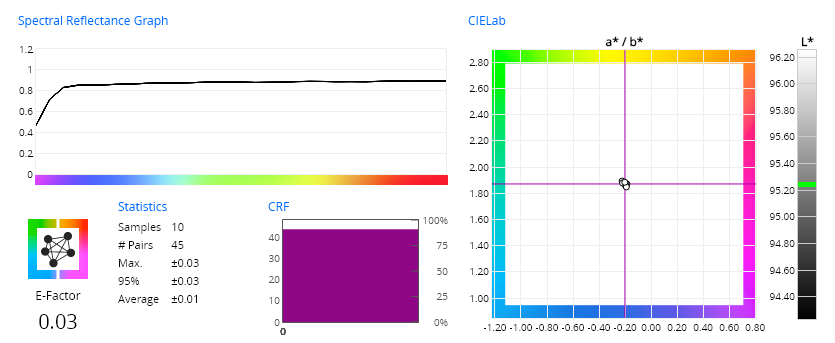

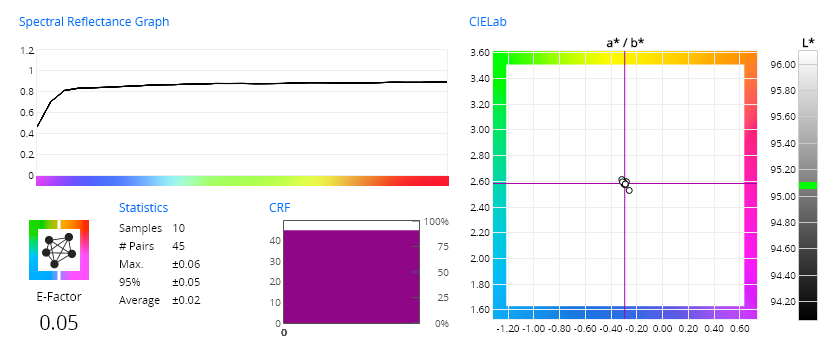

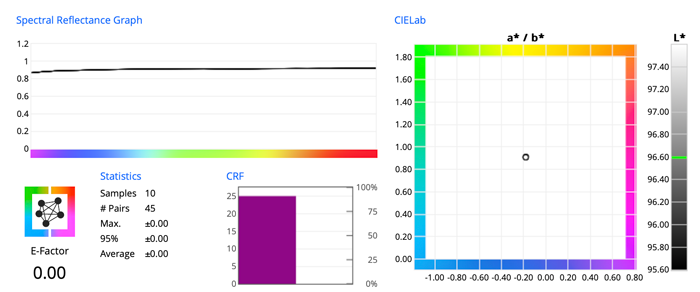

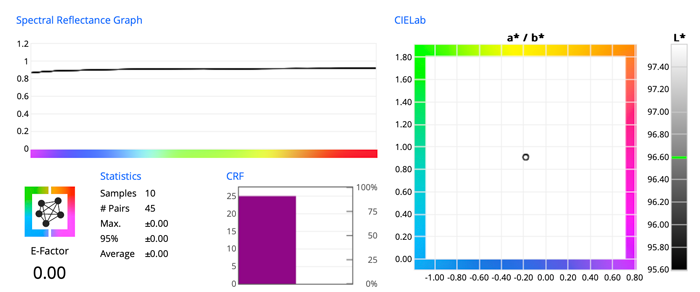

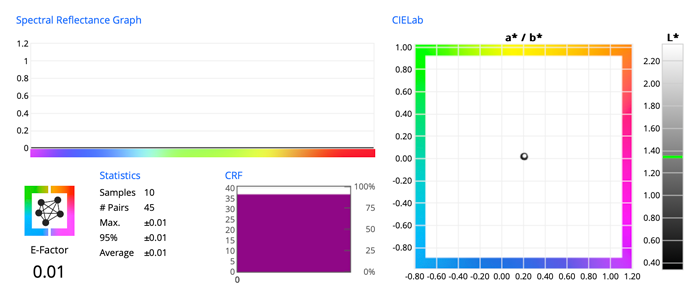

- White BRCA (manufactured by Lucideon) - repeated 10 times.

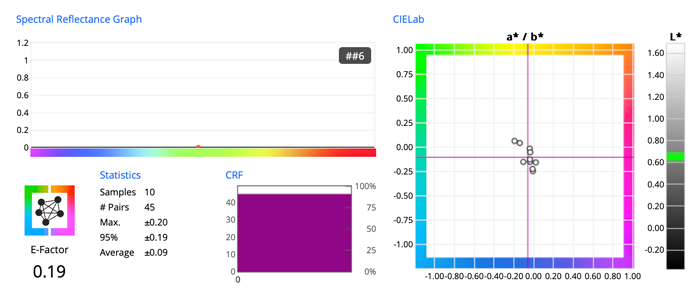

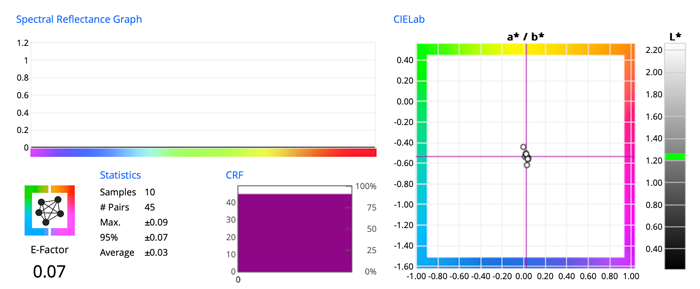

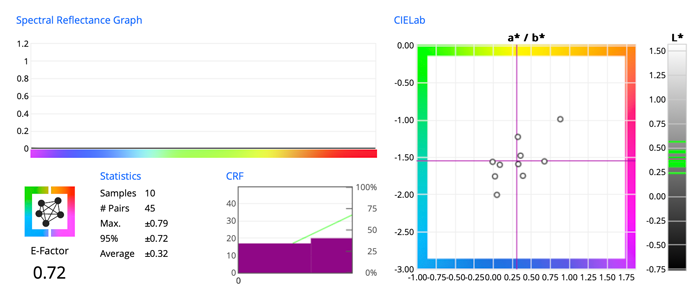

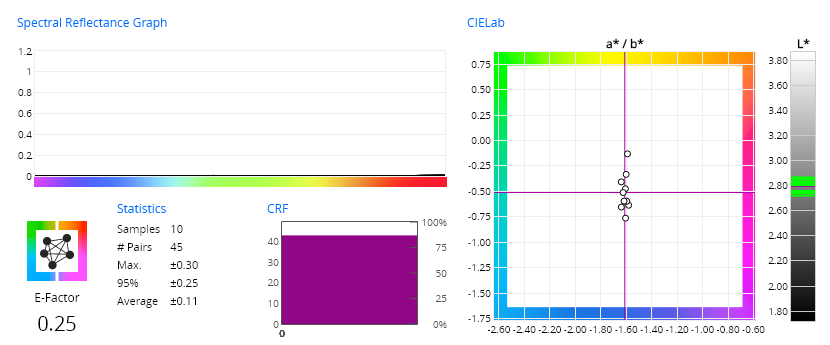

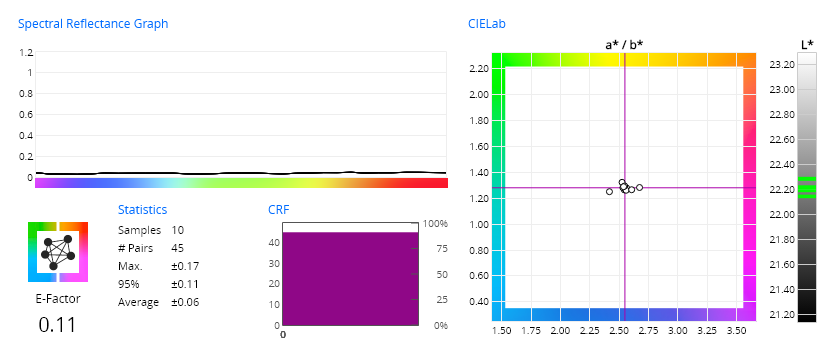

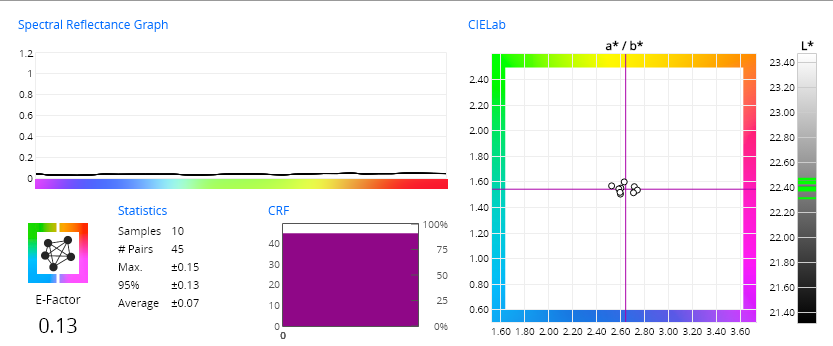

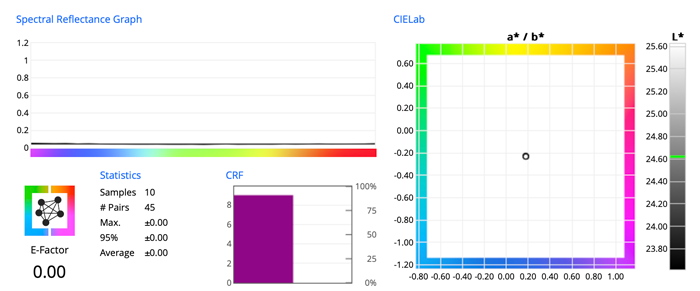

- "Piano Black"- measuring Gloss Standard (95.8 Gs) - repeated 10 times. We need to compare it to the first test. Piano black is the darkest physical object that can be sampled in color manufacturing. In this test, we expect the largest variation between measurements.

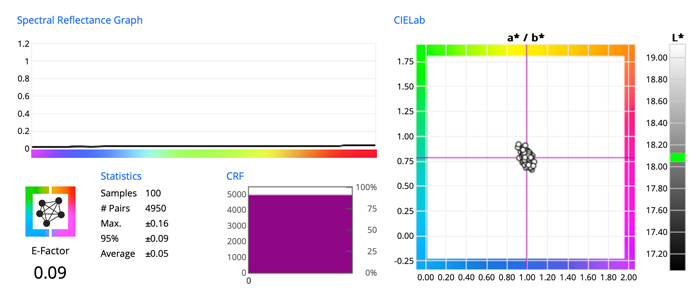

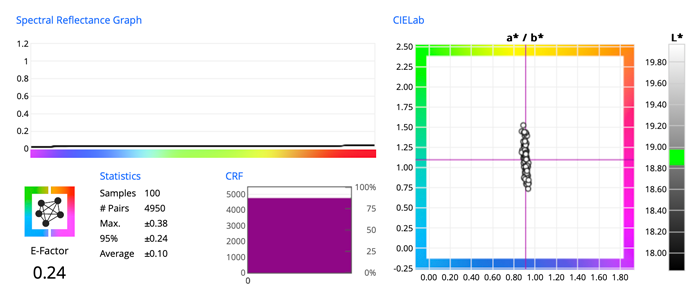

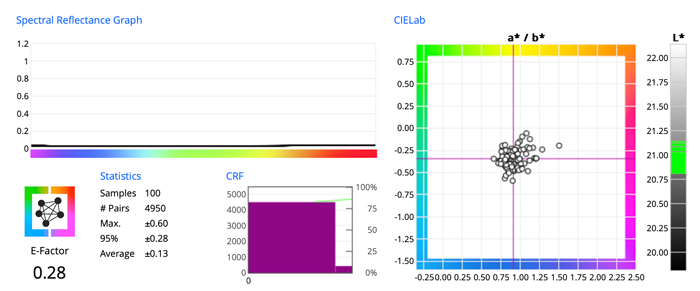

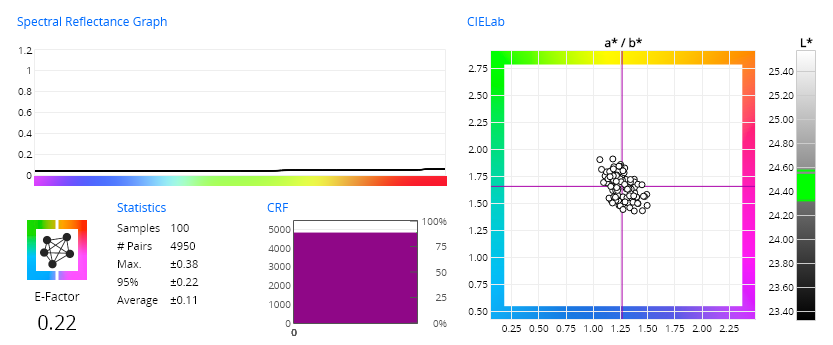

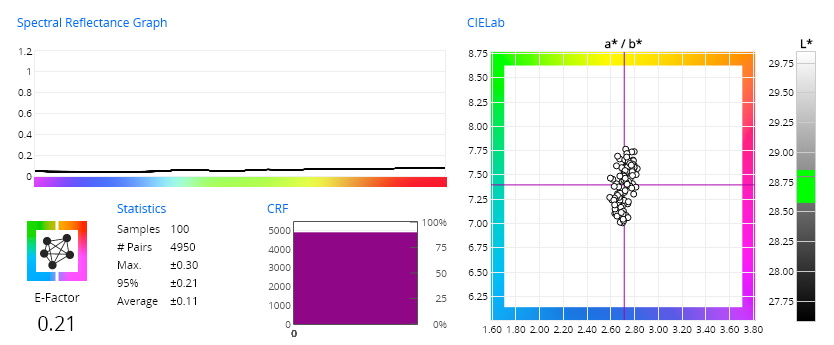

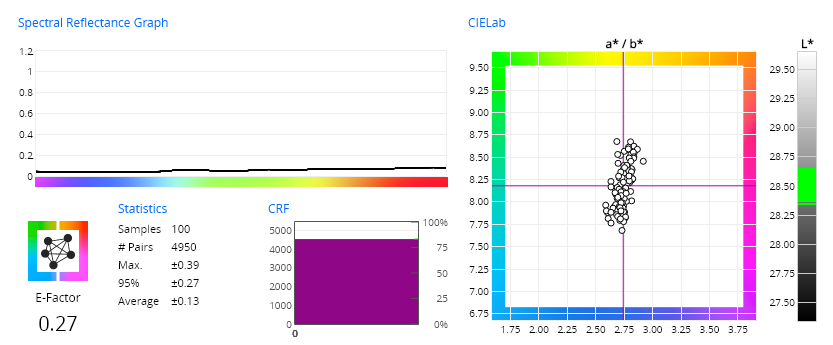

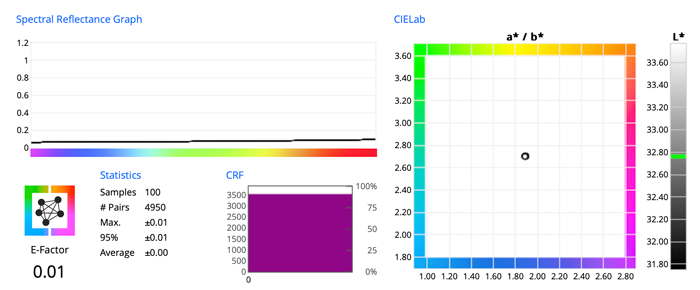

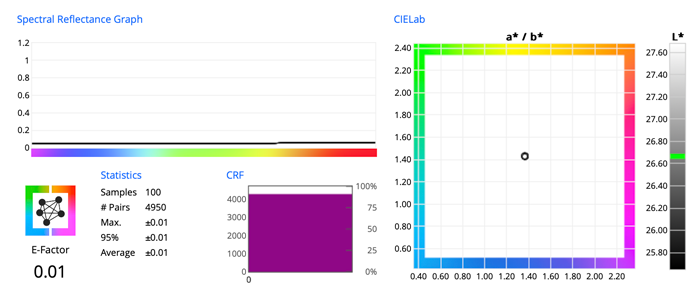

- Printed Black- Measuring black print on coated paper (Visual Print Reference by UGRA, coated matt paper, 100%K sample on page #8) - repeated 100 times. This black represents the normal print industry black, where the L* value is not as small as in the case of piano black and the repeatability error should be better than the piano black. Printed Black measurements are very important since G7 and near neutral calibration methodologies are based on two black patches (100K and 100CMY). Accurate measurements of black patches are very important.

General test rules:

- In all cases, instrument measurements are triggered from the software, without touching the instrument, to ensure no displacement has occurred.

- All tests are repeated multiple times to ensure that no improper results are published

- Whenever it is possible, results were confirmed using another identical instrument; however we are NOT saying that results are typical for specific measurement models but the unit(s) that we tested only. We are open to repeat tests with other instruments if results are noticeably different from what is expected

- All instruments are in factor calibrated condition to ISO 20231-2020, and never used in a dusty industrial environment, with the latest firmware, calibrated and maintained with care.

- All measurements are made using the CC Capture QuickChecker - Start Variation tool. If possible M1 M condition was used, D50/2° used for Lab conversion.

| 1. White BRCA | 2. Black Piano | 3. Printed Black | |

| X-Rite i1Pro 3 |

|

|

|

| X-Rite i1Pro 2 |

|

|

|

|

X-Rite |

|

|

|

| Myiro-1 |  |

|

|

|

Calibrate ColorChecker Studio |

|

|

|

| NIX Spectro 1 |

|

|

|

| Variable Spectro 1 (power) |

|

|

|

| Variable Spectro 1 PRO (power) |

|

|

|

| Variable Spectro 1 Pro (battery) |

|

|

|

| CC Sphere SPIN 11mm |

|

|

|

| CC Sphere SPEX 11 mm |

|

|

|

Conclusions

Compare your instrument with our experiment and learn about your instrument's variation; it might be different from what our test shows.

When comparing I1pro 3 vs. version 2 we can see numbers that are reduced by half. This is a nice improvement.

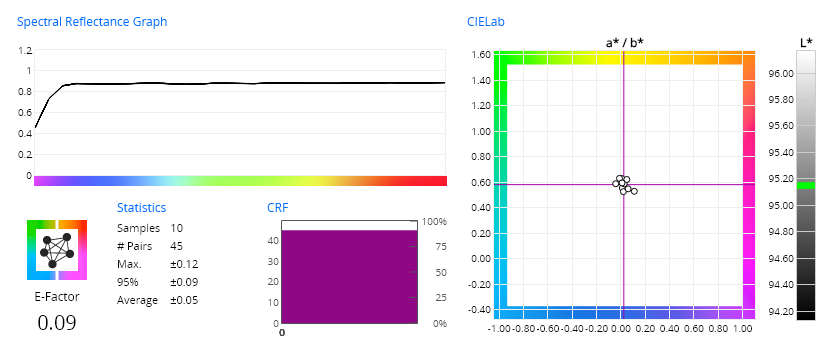

CC Sphere is incredibly stable when compared to any other instrument. This instrument is equipped with patented technology where an additional internal spectrophotometer analyzes the source of the light and compensates dynamically for potential differences. We know that most of sources of the light (within instrument) are not absolutely stable. CC Sphere improves the stability of the internal light source very effectively.

The temperature may change some parameters of the light. We can observe that some of the instruments have variations in the b* values - which means that the white point temperature could be a problem. We know some high-end instruments use systems that have stabilized LEDs using a complex high efficiency cooling systems; but such solutions are only for in-line instruments, not for handhelds. Instruments like Variable Spectro1 have a temperature sensor that prevents measurement when critical components are too warm. This forces a delay of one minute until the next measurement can be made to ensure the lighting has recovered to the correct temperature.

In most cases, we can observe that instruments equipped with gas-filled tungsten are less repeatable.

Variable Spectro 1 when operating on the battery is less repeatable than if powered using the USB cable. The voltage of the battery has a visible impact on measurements. Also, in the case of Spectro1 Pro the first 30-40 measurements are much more repeatable. Past 40 measurements the results are "colder" which means the b* value is decreasing which means for 100 measurements the shift is -0.75. This device is warming up during operation, a long series of measurements is less accurate compared to a short set of 20-30 values (more visible in the Pro version). Interesting that the Pro version when measuring 100 samples start with very good repeatability and it diminishes after about 30- 40 measurement, while the standard version seems to have higher variations in the beginning and slightly improves overall results during a series of 100. It appears that the white point temperature is changing starting warmer and getting colder (observed on PRO version only). THis is important to know when building an ICC Profile which takes at least 100 measurements. The Variable1 IOS/Android smartphone application recommends waiting up to 30 seconds until the next measurement is taken. Such long time interval makes any complex task (Like G7 Curve, or ICC Profile) hard to perform.

Additional notes:

- Instruments reporting Lab values with different values. Please take into account that CC Sphere uses SPIN and SPEX modes - depending on glossiness difference might be bigger (compare L* value difference for glossy Piano Black and matt-finished Printed Black). SPIN or SPEX readings give different values than typical graphic industry geometry 0/45°.

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.