Applying ChromaChecker 3 Step Methodology to Three Different Substrates

We will test 3 different substrates that are textile related using the ChromaChecker 3 Step methodology for qualifying if the instrument is appropriate to measure the print condition (substrate+ink).

The first three instruments that we will apply the three step process are:

- X-Rite i1 Pro 3

- X-Rite eXact 2mm

- CC Spere

The same methodology can be applied to any other instrument. All tests are performed on CC 11x17 White Backer (ISO compatible) - as our samples are not opaque.

We have samples printed with solid black ink.

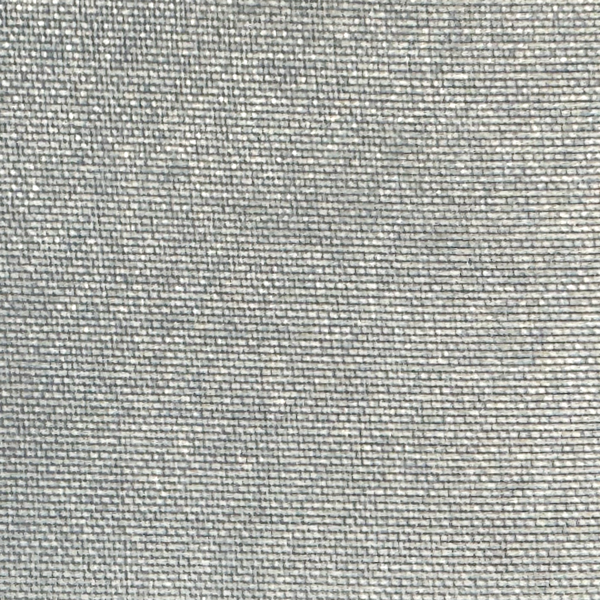

Before you begin - a closer look at three textiles.

All selected textiles are synthetic, polyester-based. The printing is performed on transfer paper using ink-jet LFP, and next thermal transferred to the textile.

1. Visual qualification.

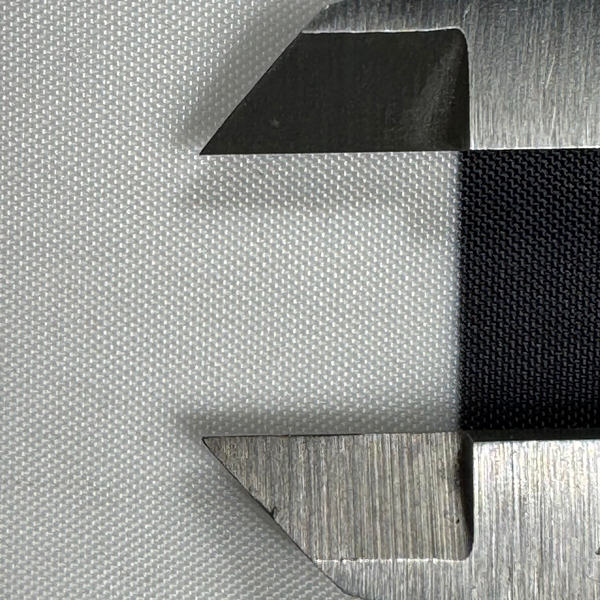

| Textile A | Textile B | Textile C | |

|

|

|

|

| close-up |  |

|

|

| conclusions: |

When we observe the fabrics closely, we see that despite using the same raw material, polyester, the fibers have a different form and are woven in a different way. The purpose of the fabrics also differs, fabric B is used for flags and fabric C is used for banners. The first chiffon fabric can be used to create curtains or used for clothing items. It has a very fine weave, is soft to the touch, and drapes nicely. Fabric B is slightly stiffer and its weave makes it very durable. Fabric C seems to be like cardboard - it has similar stiffness and is mainly suitable for straight, flat surfaces. |

||

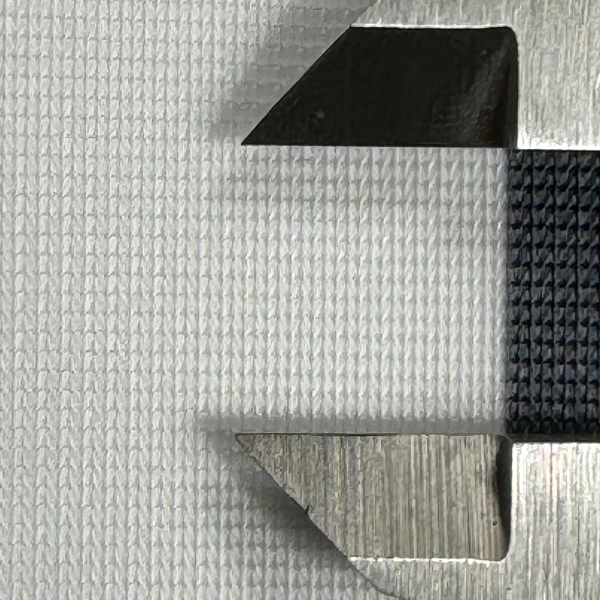

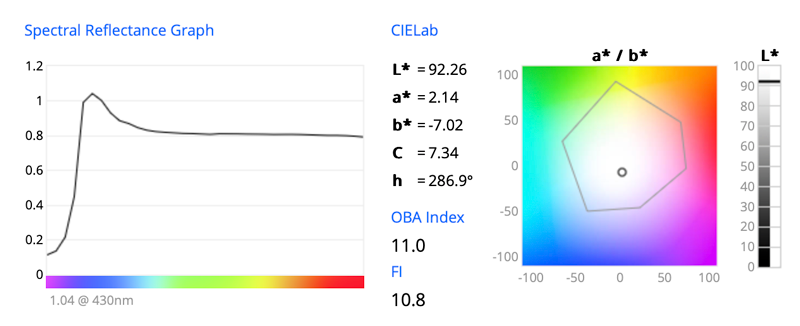

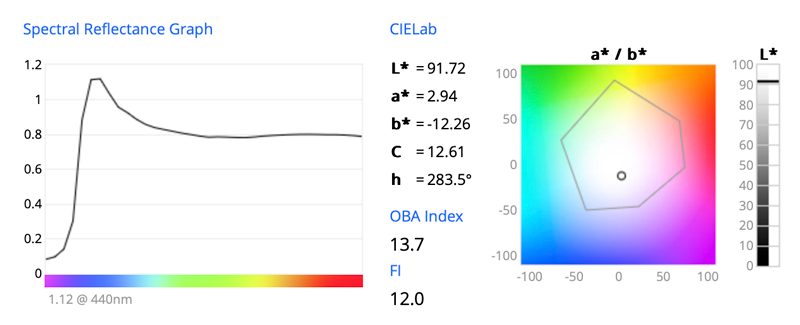

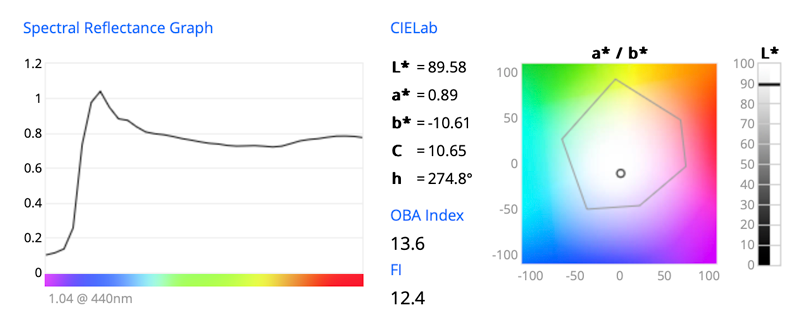

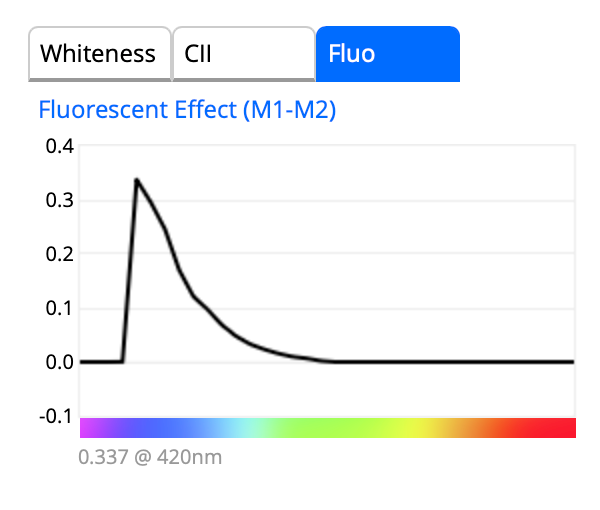

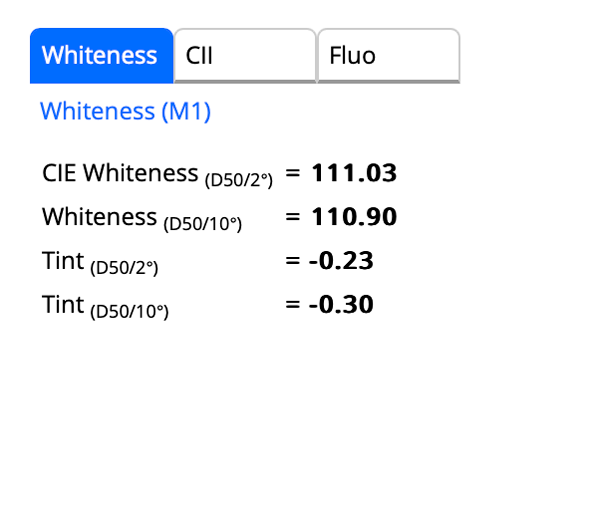

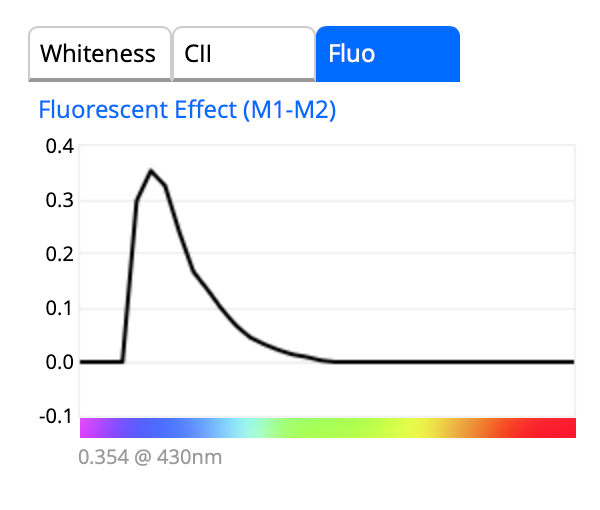

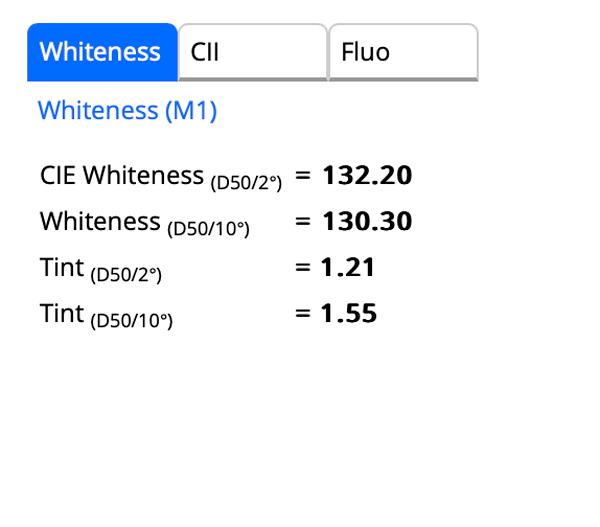

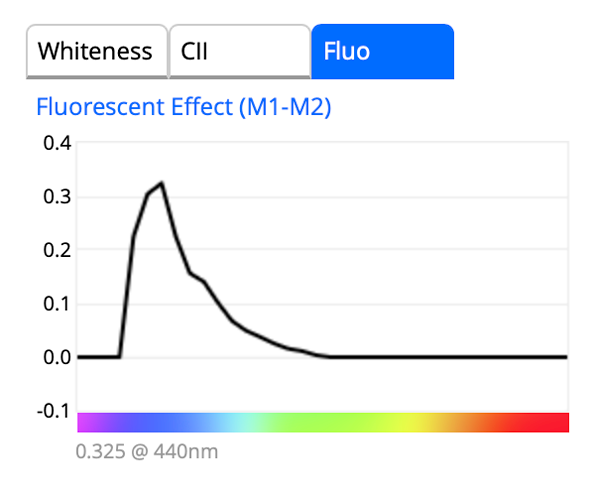

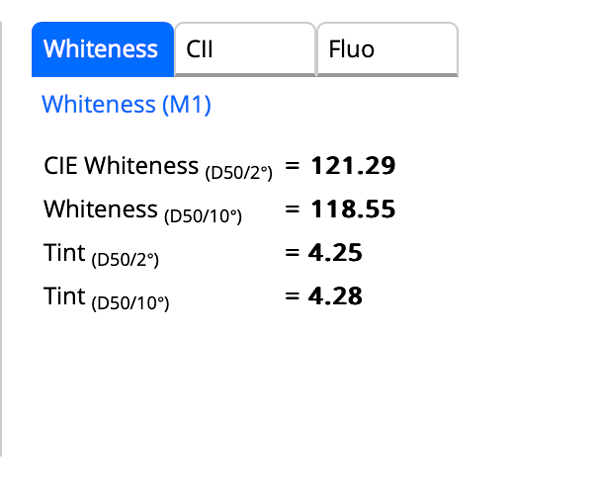

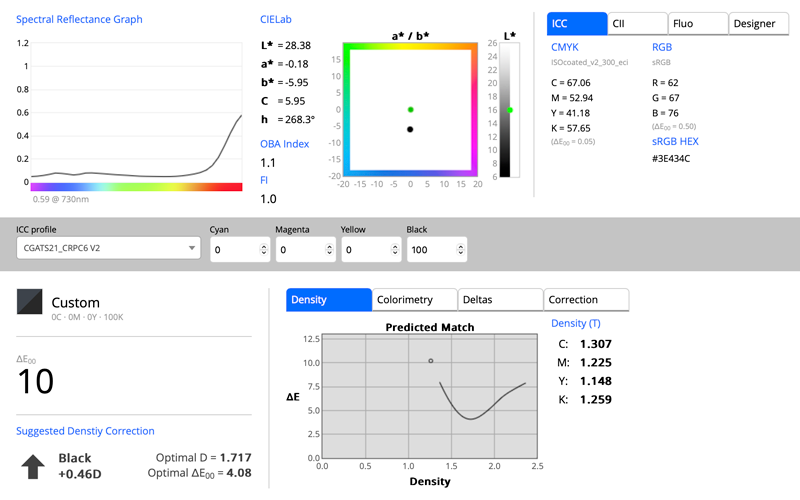

2. What about fluorescence/optical brighteners? Is UV critical for our samples?

This is important to select M-condition ( M1, M2, M3...) or make a decision if we should switch UV on or OFF in case of a spherical instrument).

CC Capture QuickCheker has a special "Substrate" button that makes it possible to adopt reports to substrates. We are using this tool with the i1Pro3, which is perfect fir this task.

| Textile A | Textile B | Textile C | ||||

| spectral curves, CIE Lab, OBA Index FI |

|

|

|

|||

| fluorescence |  |

|

|

|

|

|

| conclusion |

With OBA Index > 10 and Fluorescence Index > 10, we are dealing with materials very sensitive to UV components in the light. Lighting conditions will affect human perception of white and all printed colors. We advise switching UV ON/prefer M1 for both process control and quality control measurements. The final decision should take into account the lighting condition for the final product. If for example used for indoor applications where LED lighting systems may not contain UV components in the light - then selecting M2 / UV OFF should be selected. Measure target Lighting Conditions to make a final decision. |

|||||

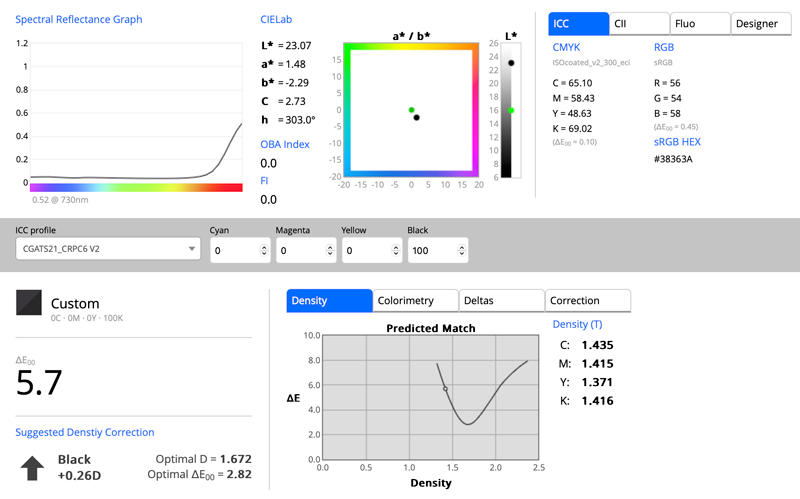

3. Printed Black - Optical Density Comparison.

CC Capture / QuickChecker can calculate optical density when the substrate is measured first. The goal is set to GRACoL but semi-transparent Textiles A and B are not able the match GRACoL. Additionally, Textile C is not fully opaque and was printed double-sided - which makes samples hard to compare. We are publishing values to show that this kind of test might help to better understand the raw materials.

| Textile A | Textile B | Textile C | |

| Printed Black |  |

|

|

4. Substrate Inspector

At this stage, we are skipping more tests that can be done using Substrate Inspector to analyze for example opacity or other parameters. The goal of this exercise is to learn how to use a 3-steps methodology to choose the best instrument for our object. We recommend deeper research with the Substrate Inspector.

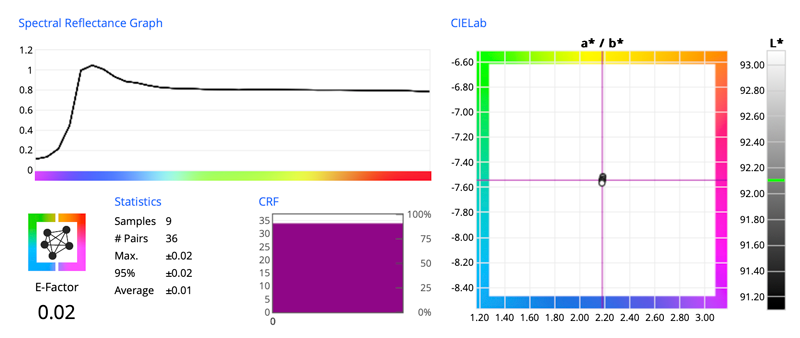

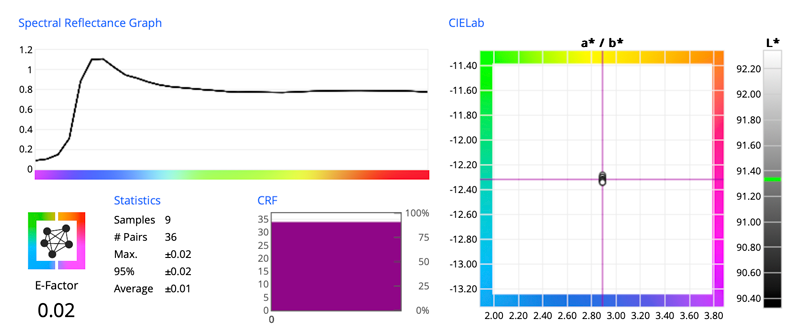

X-Rite i1 Pro — Step 1

The goal of this step is to learn what is real short-term instrument repeatability. That is required to understand how instrument imperfection can influence the results of other steps.

| Textile A | Textile B | Textile C | |

| Substrate |  |

|

|

| Printed Black |  |

|

|

| conclusion: |

X-Rite i1pro 3 is a very stable, predictable instrument. The short-term repeatability even on printed black is very good. Test repeated with random intervals gives the same results, with no warming-up issues. |

||

Watch a short video showing Step One for Textile C - unprinted substrate. All measurements are triggered from the application to avoid any accidental displacements of the instrument. We are checking only short-time repeatability to understand what kind of error is produced by the instrumentation. It is quite normal that blacks are less accurate than white samples.

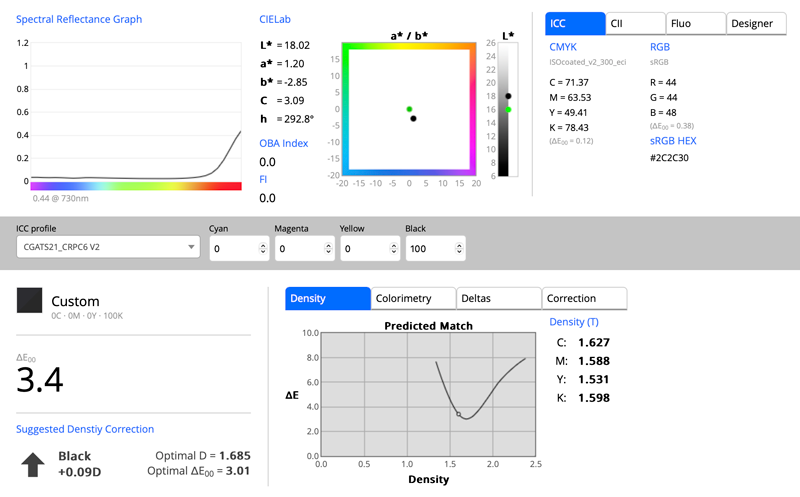

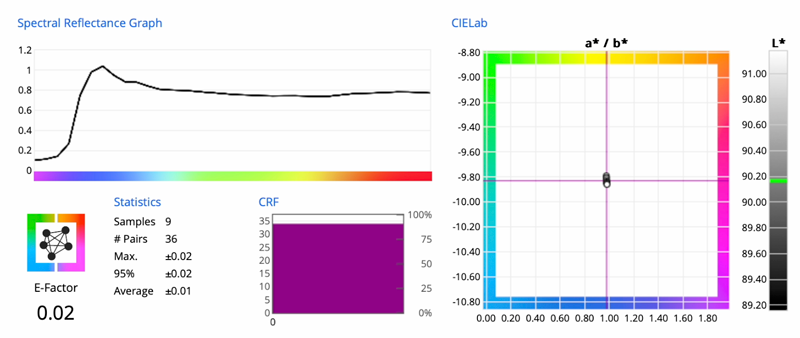

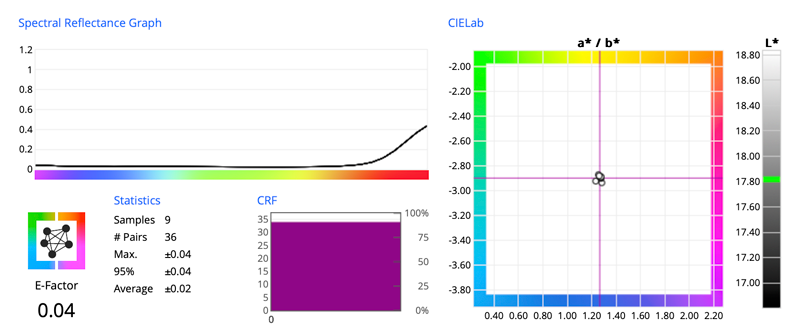

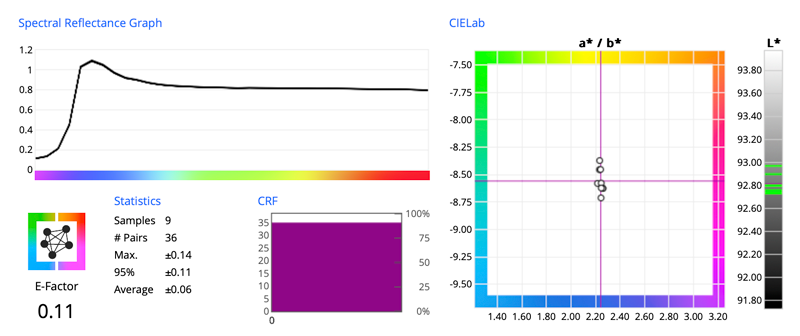

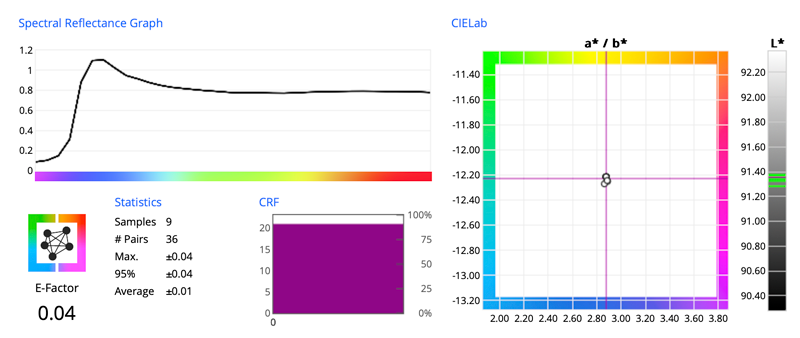

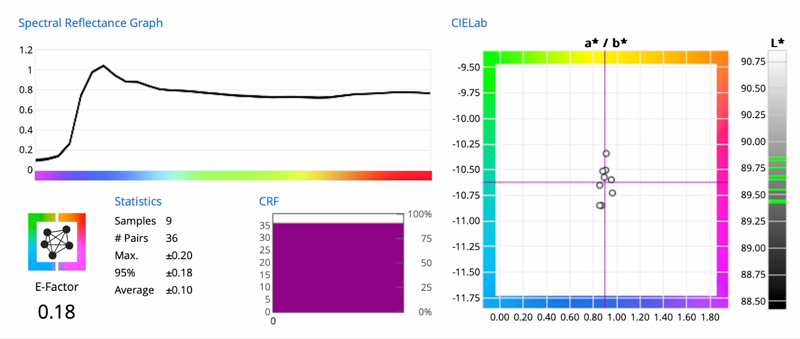

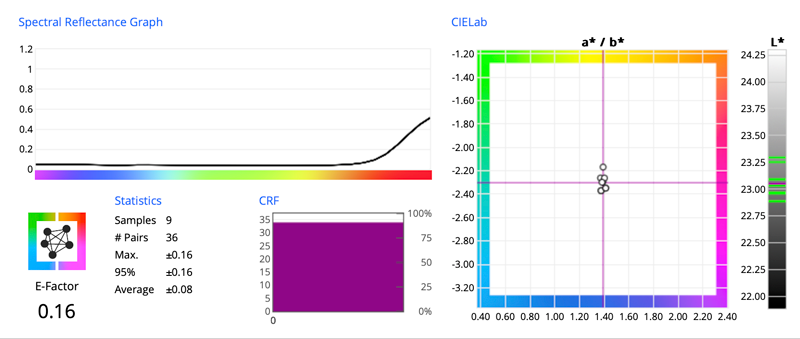

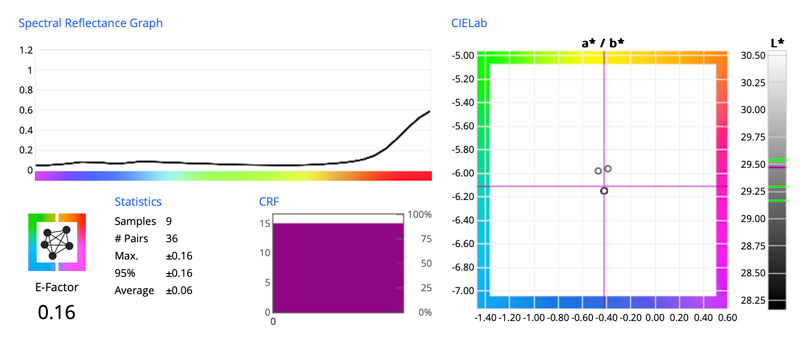

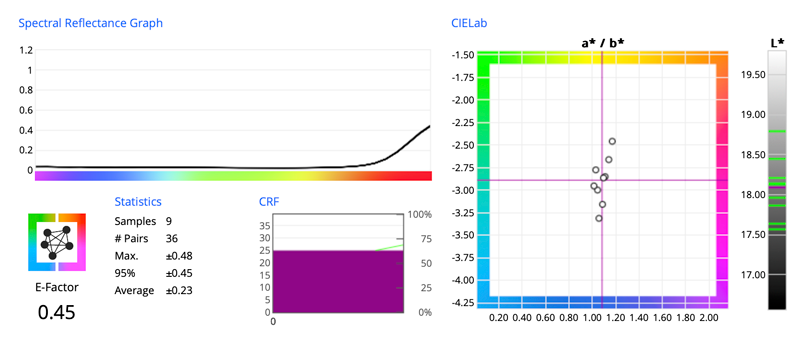

X-Rite i1 Pro — Step 2

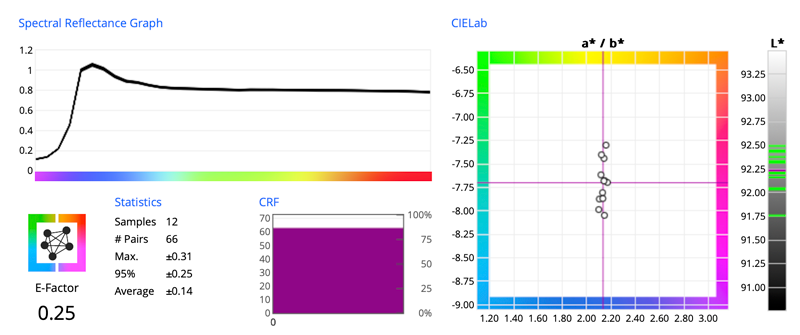

In this test instrument is slightly replaced but without rotations. Smoother objects should have lower numbers (better) while more complex (rougher) structures can interact with the aperture of the instrument. We will also be able to see the uniformity of the measured object. Visual assessment should correspond to numbers.

| Textile A | Textile B | Textile C | |

| Substrate |  |

|

|

| Printed Black |  |

|

|

| conclusions: |

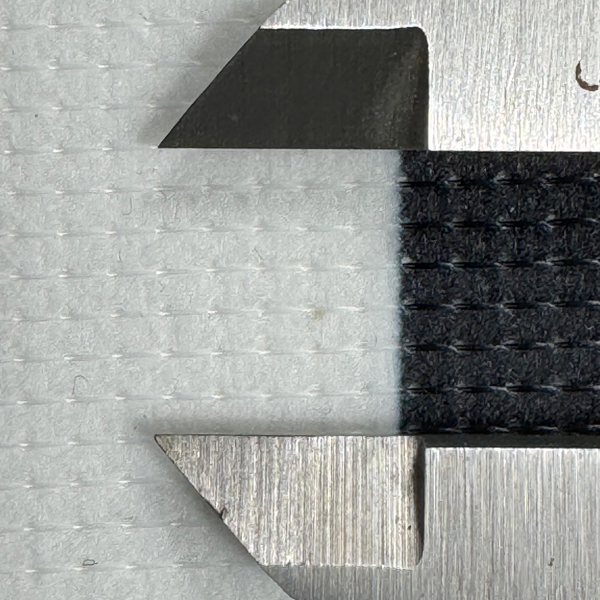

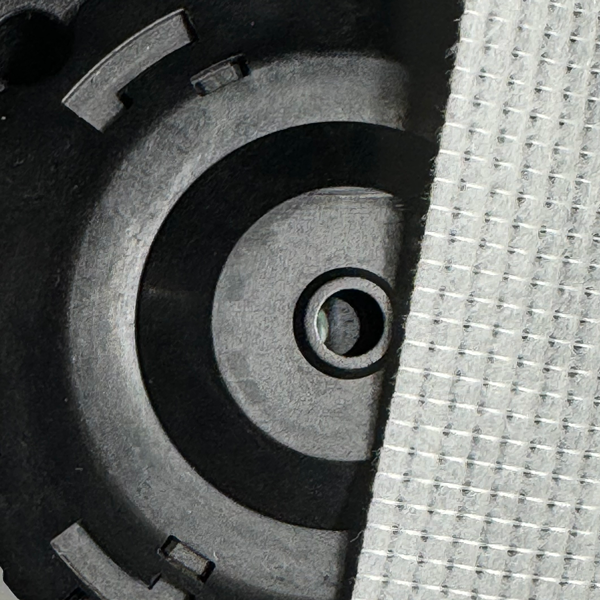

It was surprising that unprinted Textile B (0.04) had better results than Textile A (0.11). And it was expected that the coarse structure of Textile C (0.18) would give a higher error. We have repeated tests to confirm that nothing happened by accident, and the results are pretty much the same. Another interesting observation is related to printed textiles. We see that Textile C when printed is not covered perfectly. Analyzing a close-up of the textile we see that the linear distance between the dots is about 2 mm. Only a few white dots can be covered by a small aperture of the i1Pro. Small instrument displacement can change the number of dots used for averaging. Such textiles require a larger aperture. The difference in results for substrate unprinted and printed is caused by several factors - but finally is property of the object has to be managed as a sum of all factors. The main reasons why black numbers are worse than white are:

|

||

To explain why the numbers for B seem to show better homogenity we did another picture using partial backlight. The top surface of the textile looks good but transmitting light shows " internal clouds" - optically density is not uniform. 45-degree light (instrument geometry)

Additional analysis that explains results.

|

|

|

||

| Textile A in transmissive light, we can see non uniformity. |

Textile C, printed black. Spots are not printed, Instrument is averaging a portion of the image of aperture size. The number of dots covered by the aperture matters. |

Textile C and i1Pro measurement head. |

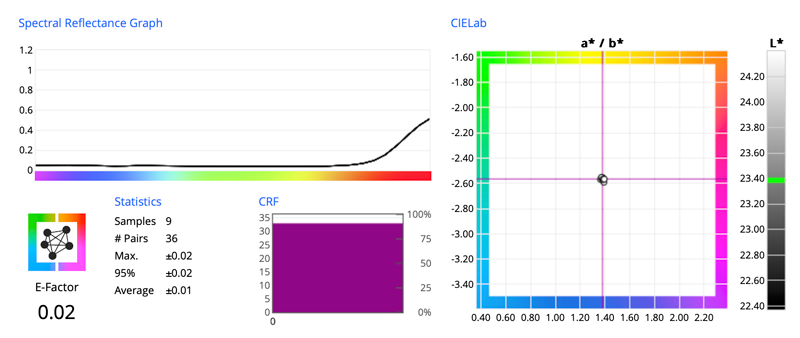

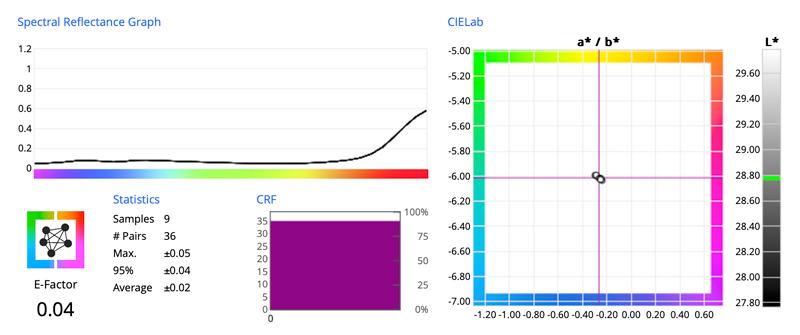

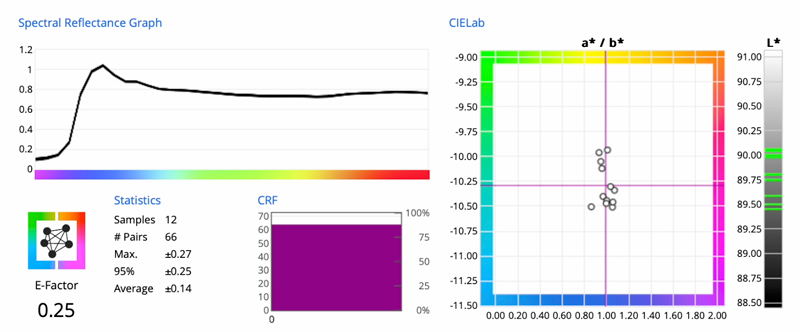

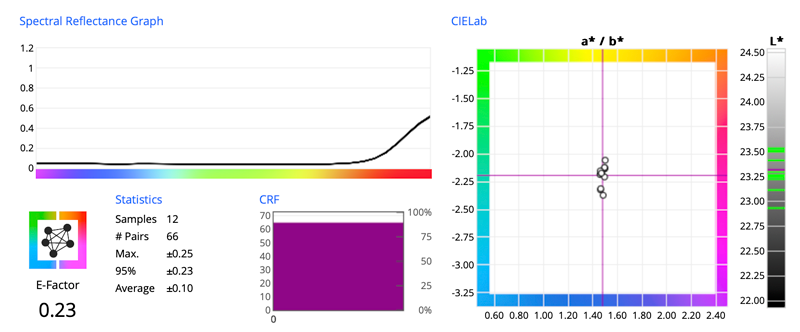

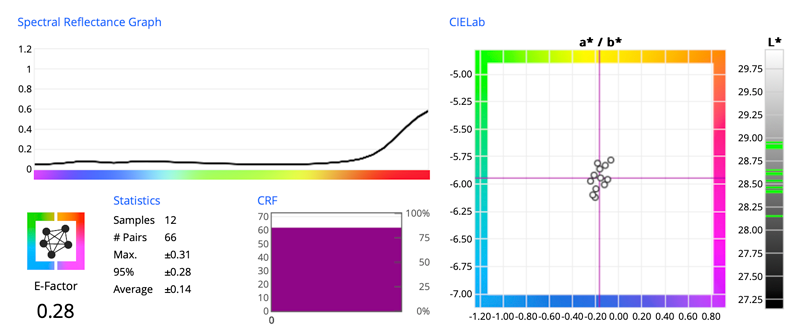

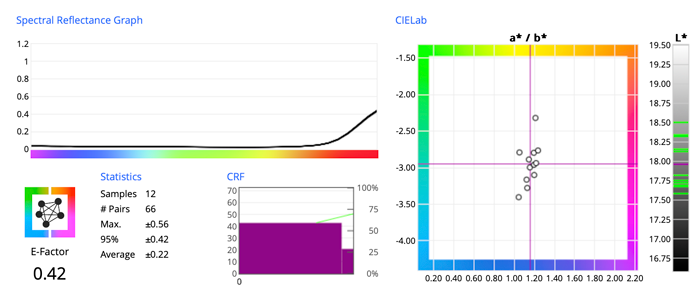

X-Rite i1 Pro — Step 3

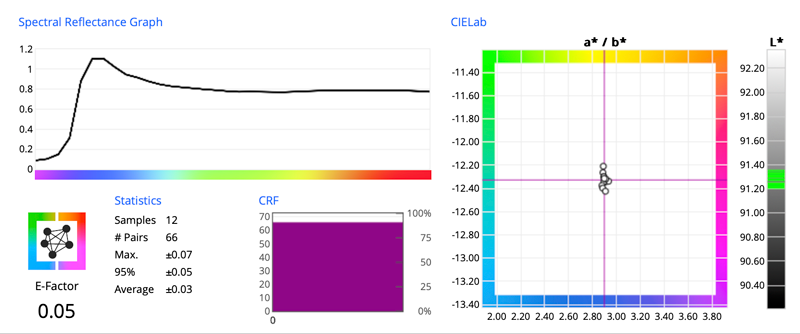

In this step we are rotating the instrument, as this is a manual process it is also combined with displacement.

| Textile A | Textile B | Textile C | |

| Substrate |  |

|

|

| Printed Black |  |

|

|

| conclusions: |

This test proves Textile B with no printing has very good uniformity. When it is printing is applied it no longer has good uniformity. The thermal transfer printing process has a lot of variables that cause inconsistencies. Generally, instrument rotation shouldn't impact consistency of measurements but when it does, it often means you should use a larger aperture. All three substrates when printing is applied will benefit from being measured with a larger aperture using an instrument like the i1Pro 3 Plus because of the 8 mm aperture. |

||

Instruments Comparison

In this article we are showing only the final results of instrument comparison, however, all detailed data are available - click on the instrument name to access them. In the following table, we are using Variation E-Factor which is a very effective metric for such purpose.

Please note - the following table shows results for selected samples only - and is not any kind of general comparison. The purpose is to show that the same 3-step methodology. This experience allows us to understand why it is worth using this methodology because it often happens that the predictions are slightly different from the results. Simple, quick tests allow you to better select instruments for specific tasks.

| Textile A Substrate |

Textile A Black |

Textile B Substrate |

Textile B Black |

Textile C Substrate |

Textile C Black |

||

| X-Rite i1Pro 3 standard ver. |

A standard version with an aperture is not recommended for any textile. A dedicated Plus version with an 8 mm aperture is preferred. We are planning to repeat tests with the Plus version soon. iO table enables scan options - however, for the Plus version patch size requirements limit the number of samples per page dramatically. |

||||||

| 1 | 0.02 | 0.02 | 0.02 | 0.04 | 0.02 | 0.04 | |

| 2 | 0.11 | 0.16 | 0.04 | 0.16 | 0.18 | 0.45 | |

| 3 | 0.25 | 0.23 | 0.05 | 0.28 | 0.25 | 0.42 | |

| X-Rite eXact 2 mm |

This instrument with a 2 mm aperture is designed for measurement on paper substrates only. An instrument that is perfect for some applications might not be proper for other applications. | ||||||

| 1 | 0.03 | 0.05 | 0.05 | 0.05 | 0.03 | 0.24 | |

| 2 | 0.22 | 0.27 | 0.15 | 0.39 | 0.33 | 0.35 | |

| 3 | 0.36 | 0.82 | 0.81 | 1.18 | 0.33 | 0.46 | |

| CC Sphere 11 mm |

Spherical instrument - dedicated to complex surfaces has some limitations due to missing scan options. Also, the MAV (11mm) aperture gives better averaging but requires a bigger patch size. A smaller available 6 mm aperture is not recommended for textiles as it is too small. | ||||||

| 1 | 0.01 | 0.01 | 0.00 | 0.01 | 0.00 | 0.01 | |

| 2 | 0.07 | 0.10 | 0.01 | 0.12 | 0.10 | 0.10 | |

| 3 | 0.04 | 0.08 | 0.02 | 0.17 | 0.06 | 0.12 | |

| summary | |||||||

Related Topics

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.