Visual Assessment in Numerical Criteria

|

Quality → Standards → Numbers → Tolerances

To eliminate waste – define Quality. The best way is to adopt existing or create your own Standards. Express Quality with the Numbers that correspond to expectations. Write Tolerances to contract. With ChromaChecker the whole process is clear. No other system on the market offers at every stage a translation of the subjective feelings of people assessing the color and the numbers provided by measurement systems. This makes certain simplified methods that may fail to be adaptable to effectively fulfill their role. Often too many simplifications mean that the designated tolerances do not meet expectations – the same value is at the same time too loose and restrictive, which means that instead of objective numbers we rely on the opinions of people whose decisions will not always be objective. Color perception depends on the lighting conditions and the observer. While it is relatively easy to provide uniform lighting conditions, it becomes impossible to standardize people. Everyone sees color differently and how even the same person sees color depends on the mood, emotional state, rest – many factors that do not give objective conditions. Two people will see color, additionally, they will have a different structure of the eye individually – a different distribution of rods in the retina, different color sensitivity curves, but also different cultural experiences, slightly different records in the brain's memory of color (memory colors). It is a tangle of conditions and connections that is difficult to tame and seems to be impossible to solve. However, man has the ability to learn and observe. Therefore, Chromachecker has developed a series of tools to help train the observer to perceive color differences, and learn the influence of sample neighborhood, background and context. People involved in critical production processes can learn how to assess differences, improving their skills combined with a digital scale, and additionally with the possibility of comparing various mathematical formulas.

Numbers ↔ Visual Assessment

Due to the significant difference, both on the perception and technology side, the color assessment has been divided into two categories – flat colors – of the spot type have been separated or the reproduction of images, photos where we deal with a huge number of multicolored pixels making up a complex image. |

| stage | Pages and Pictures - Process Color | Spot Colors |

| Learn and Practise |

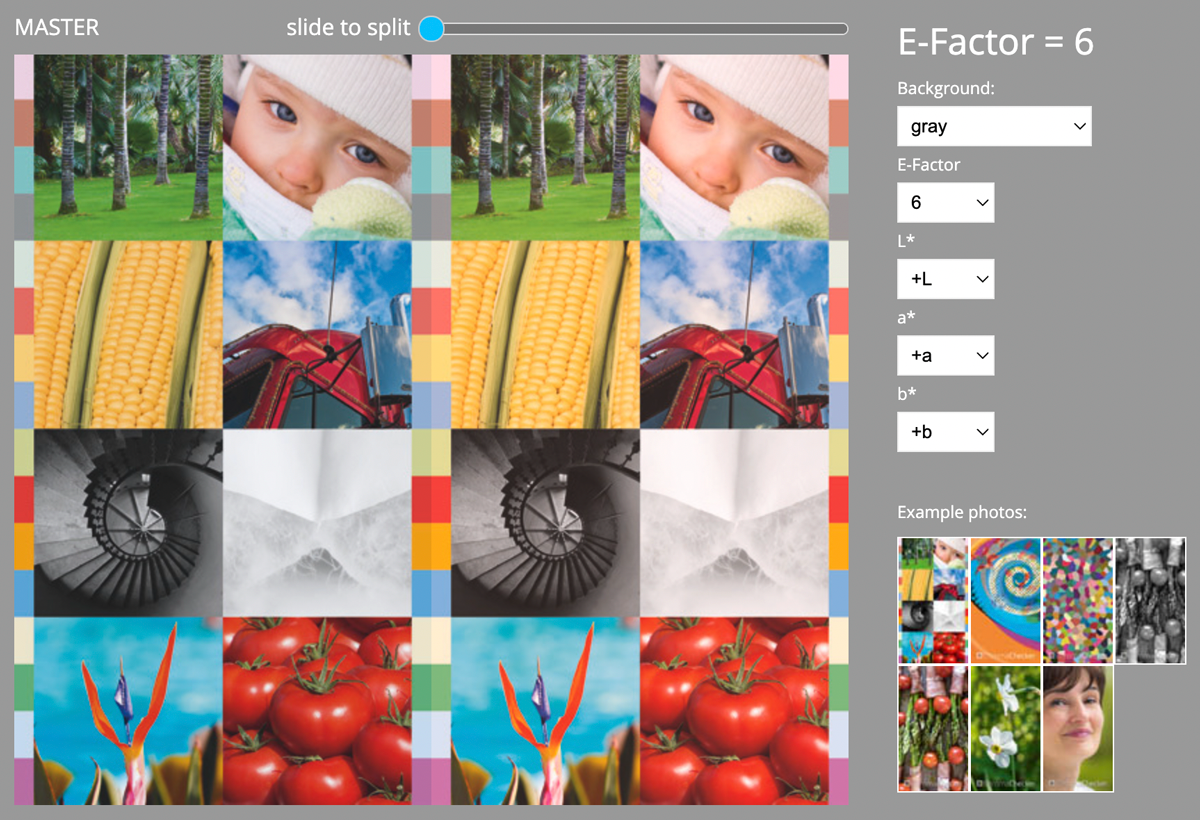

Image Color Exercise |

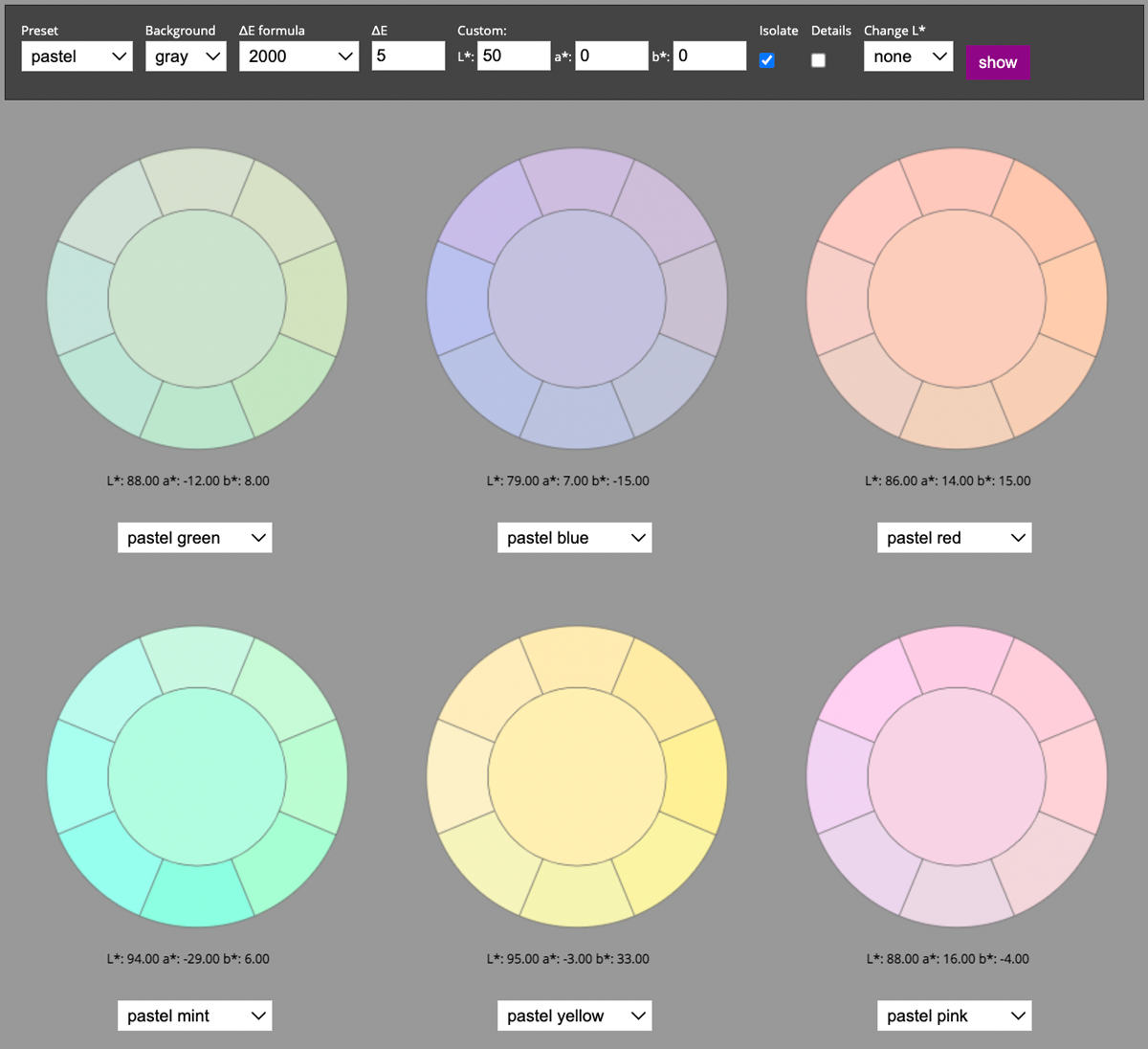

Spot Color Exercise |

|

Soft-proof Tolerance Evaluation |

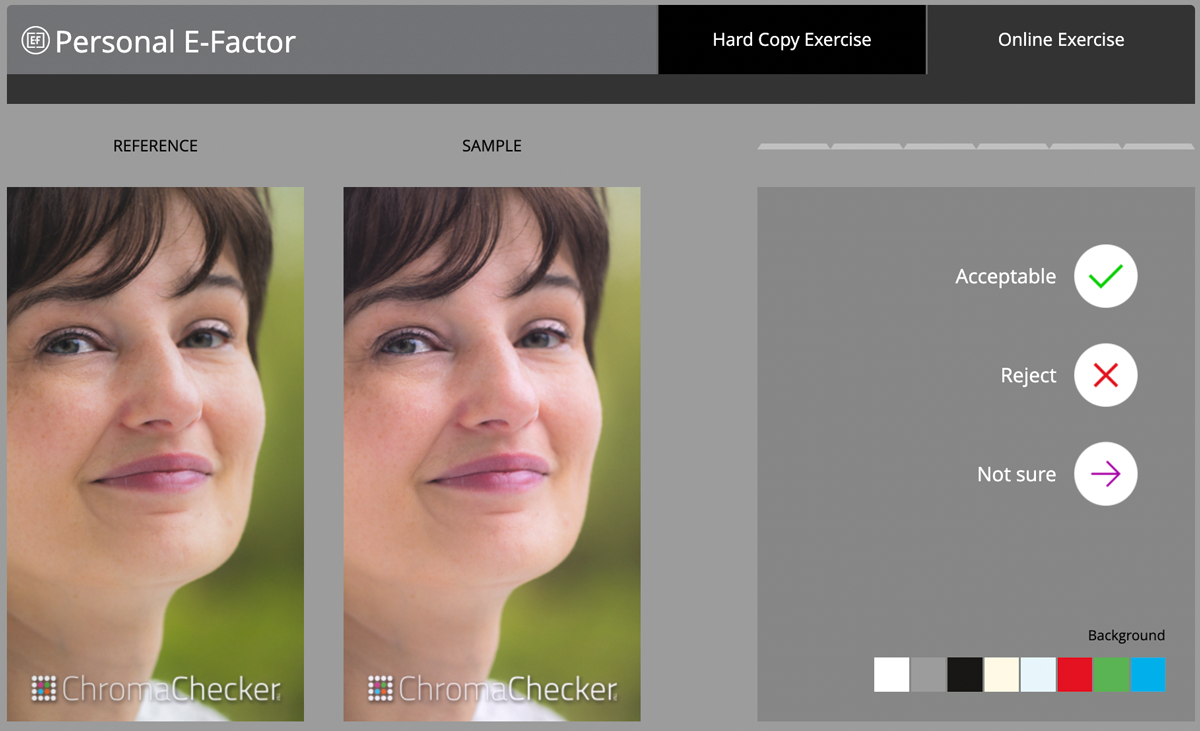

Personal E-Factor |

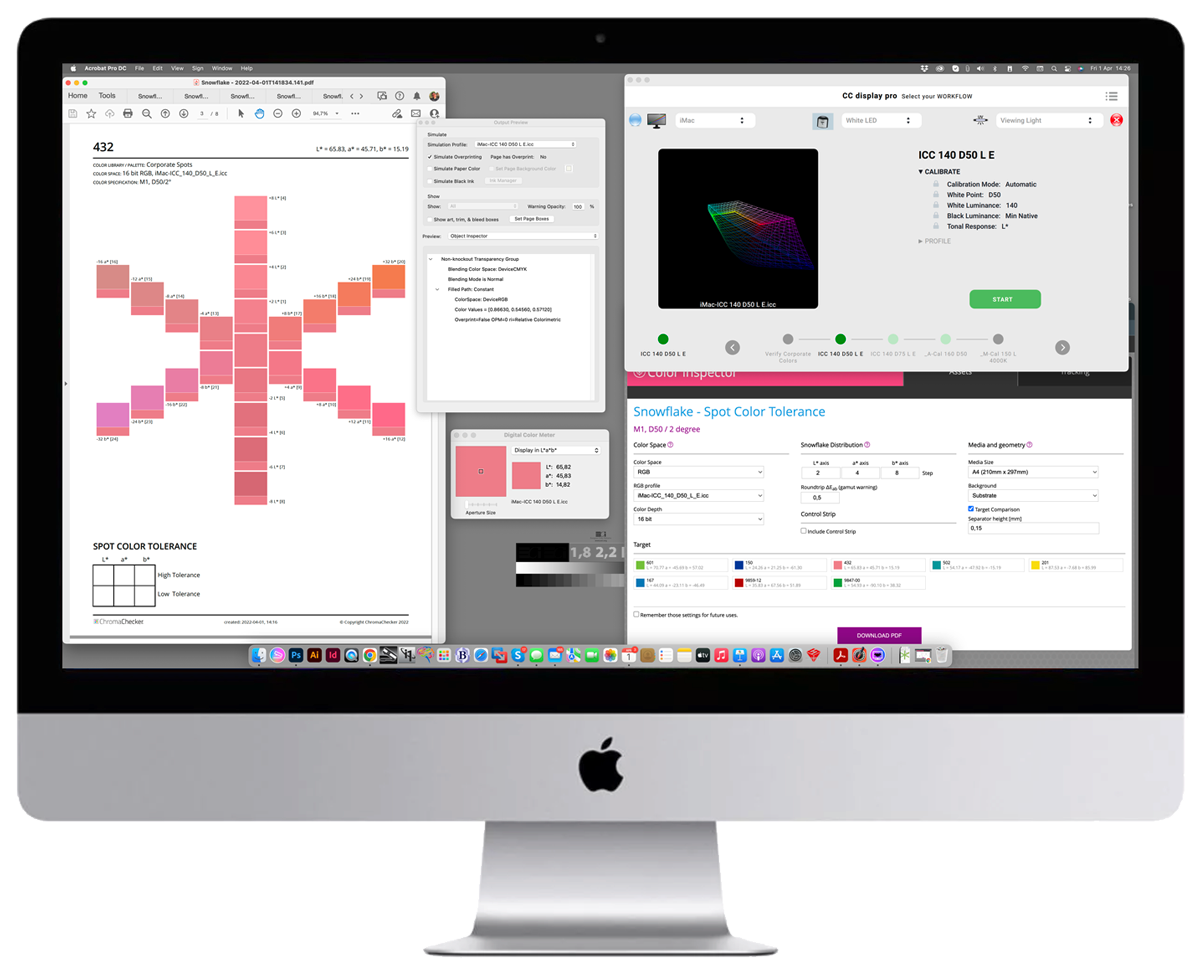

CC Display + Snowflake |

| Hard-proof Tolerance Evaluation |

E-Factor Exercise/Sampler + CC Connect App. |

|

|

Enter standards in the CC System |

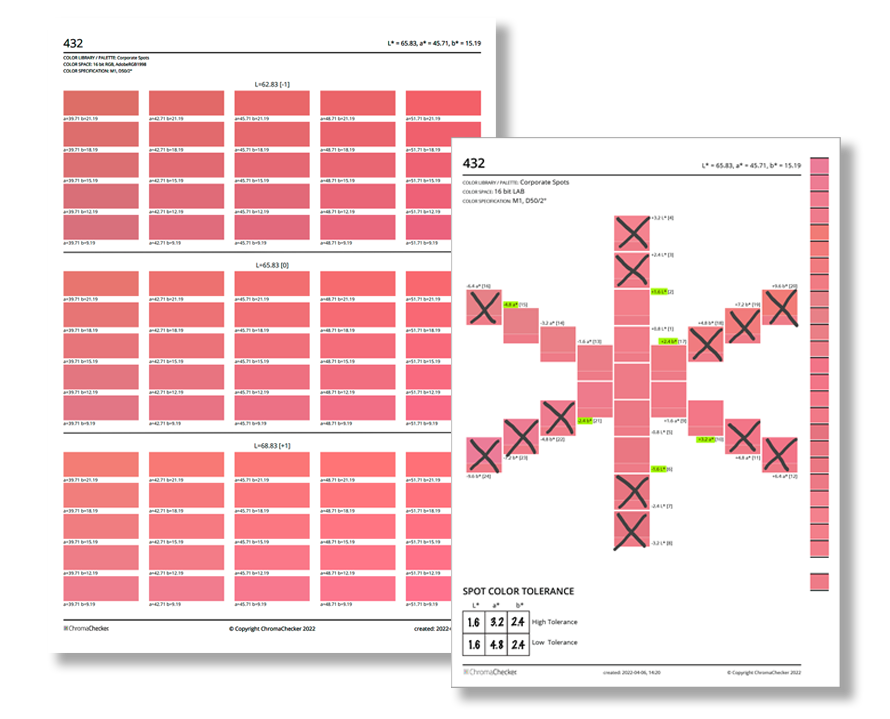

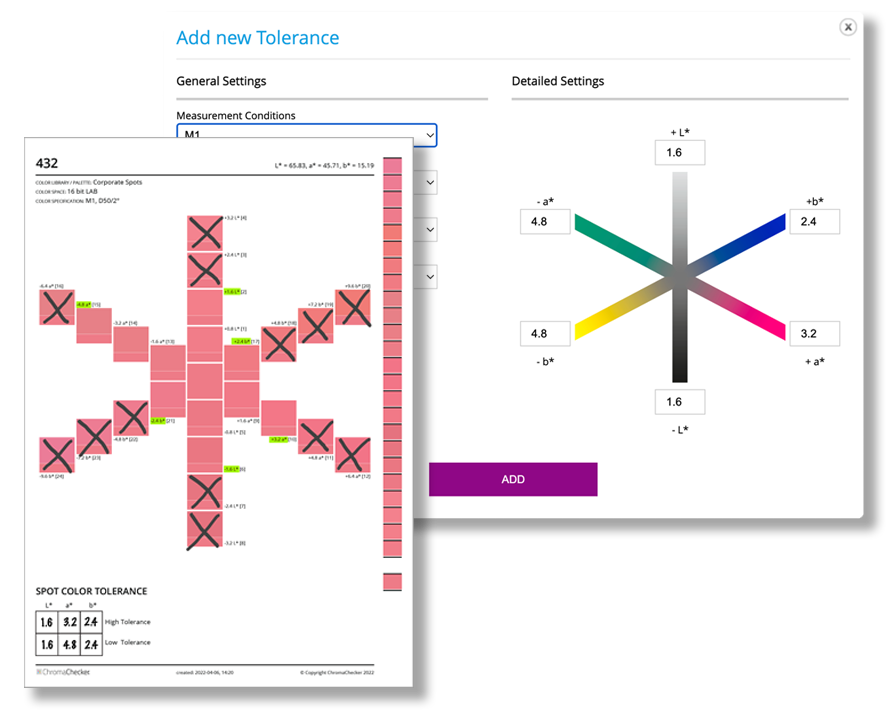

Print Inspector Tolerance Set |

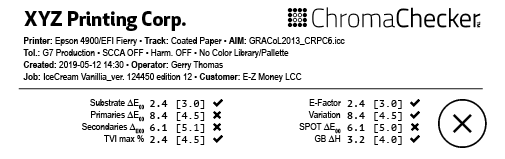

Advanced multi-level Tolerances |

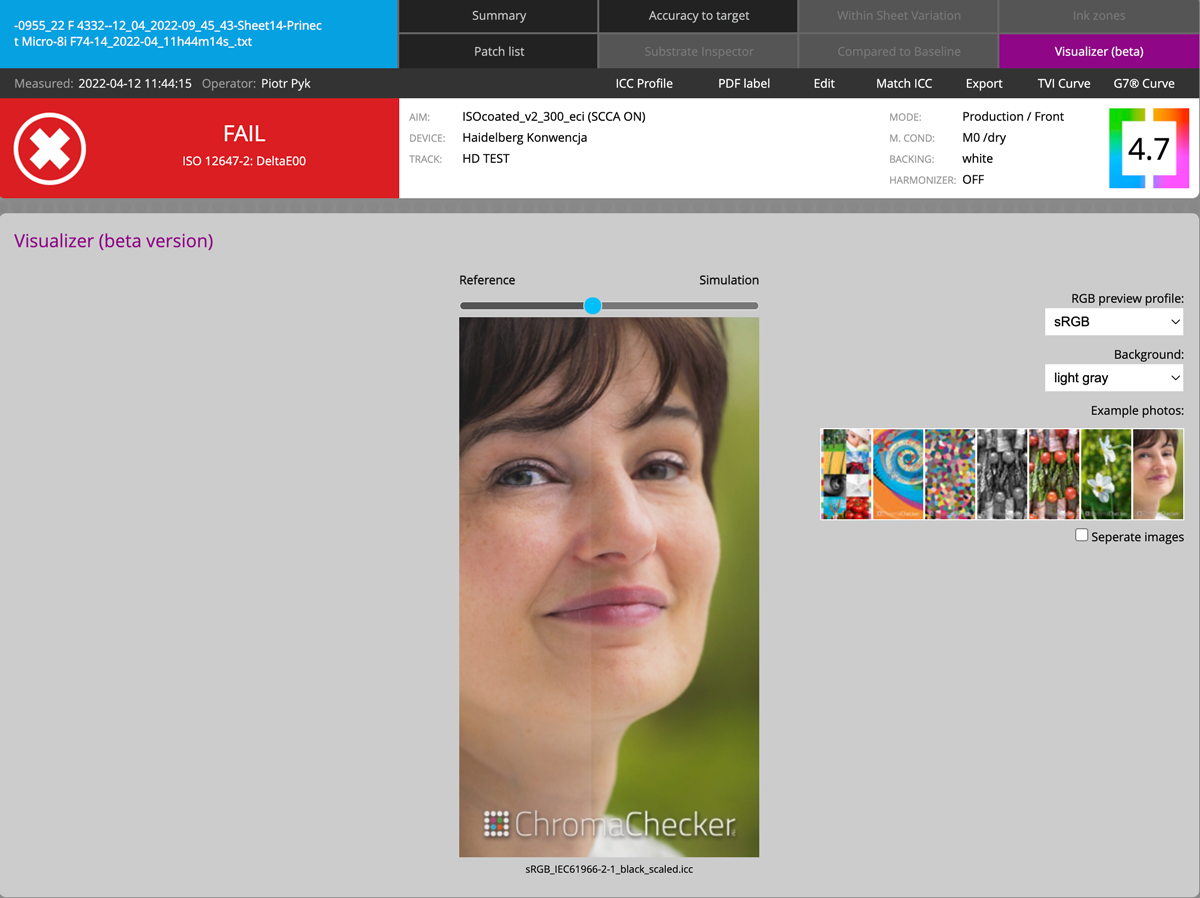

| Render on-screen simulations |

Visualizer (simulate printed result) |

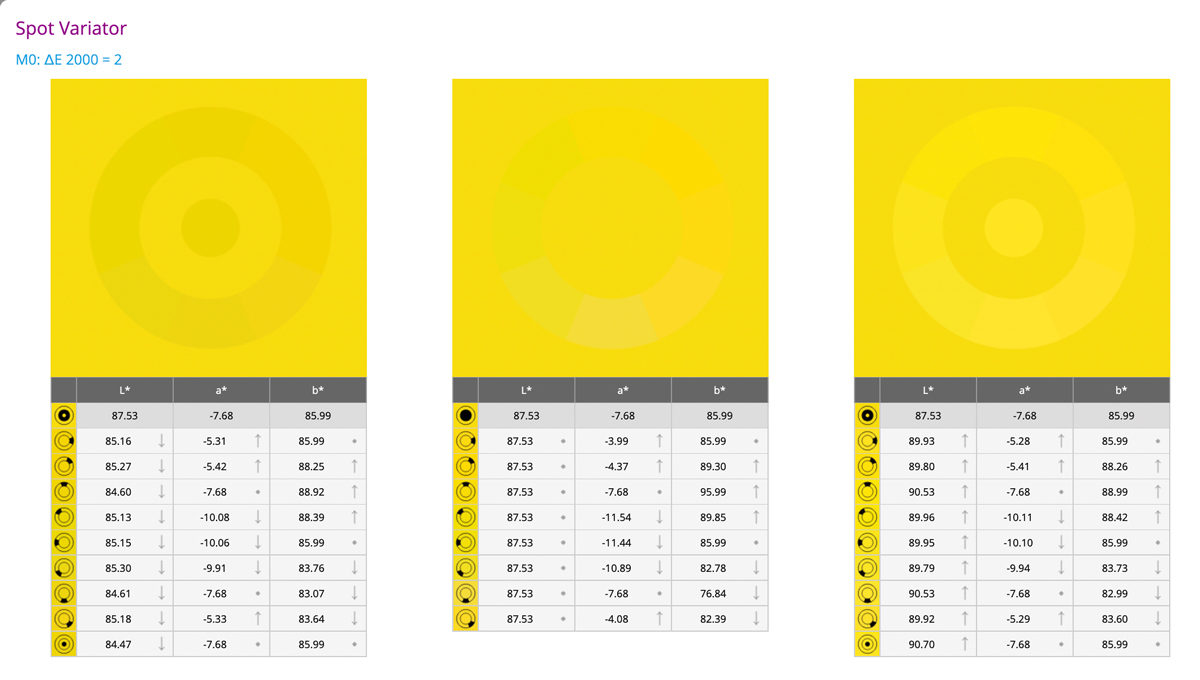

Spot Variator |

| Track Production |

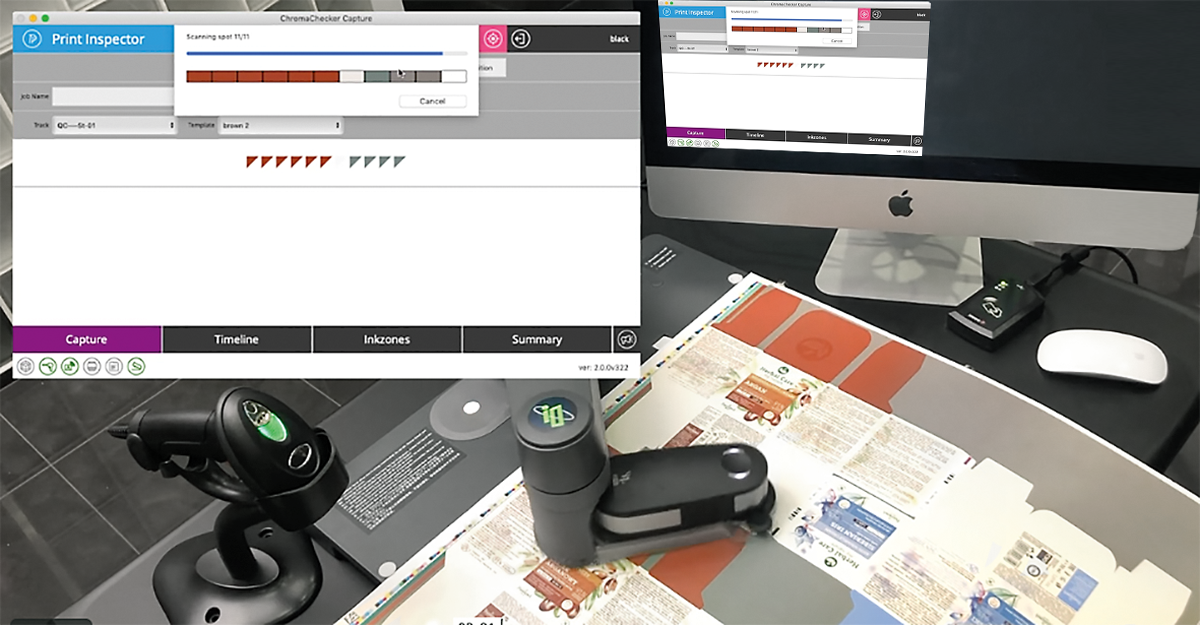

Print Inspector + Color Inspector Assets |

Color Inspector Tracking |

|

Automation |

example of barcoded Virtual Control Strip — PI Spot measurements |

|

|

Quick Labels |

CC Capture Labels/PDFs (Print Inspector. Color Inspector) |

|

| Detailed Reports | Timeline, Easy Mode, Expert Mode | |

| Performance Reports |

|

|

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.