April 13, 2022

ChromaChecker 5 step Implementation for Production Inspectors

| |

|

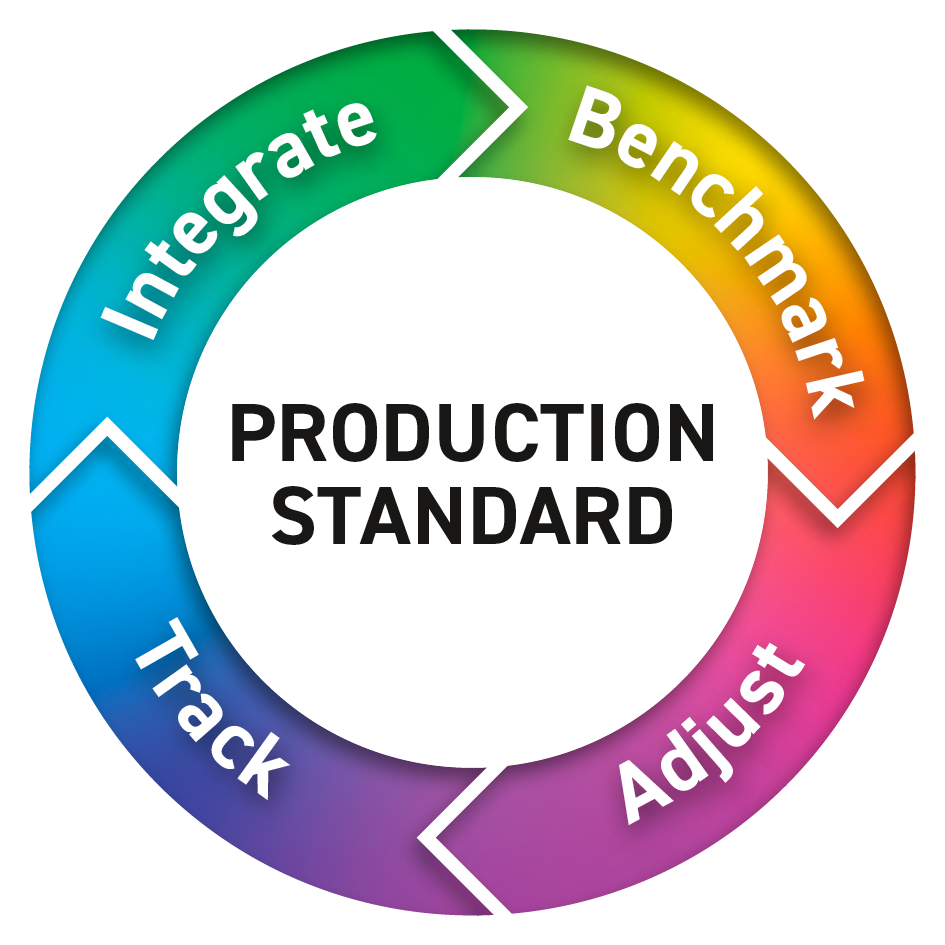

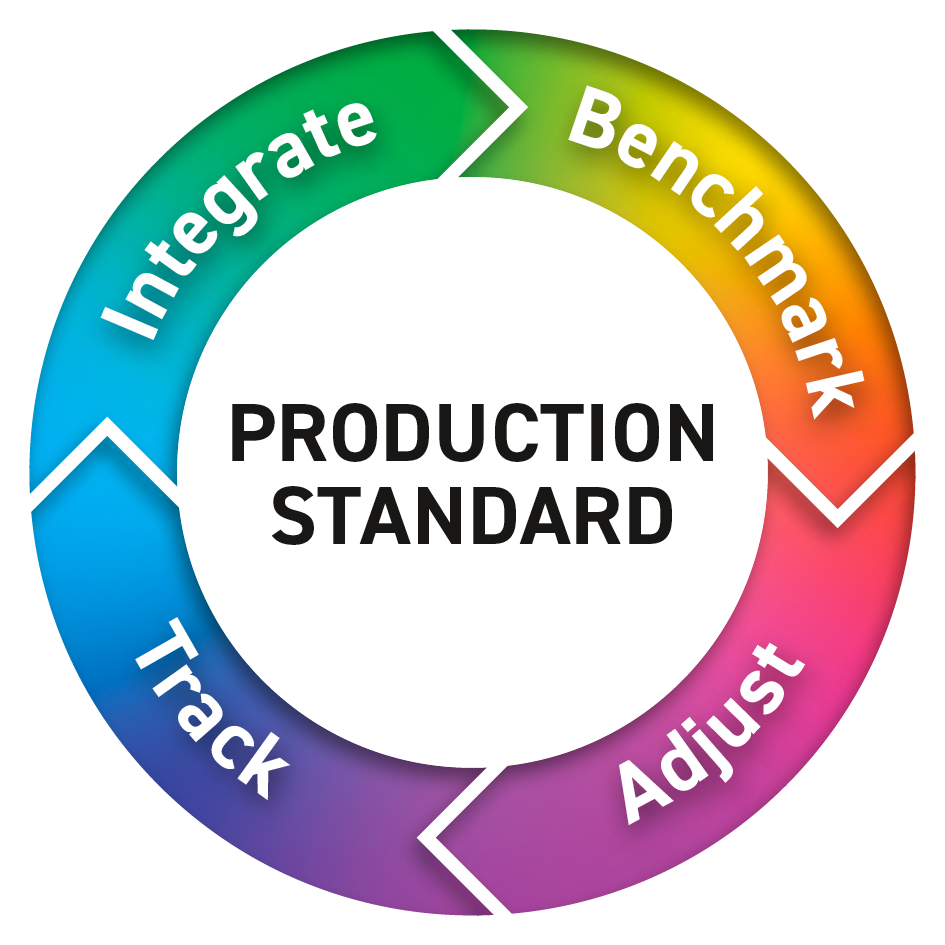

Define Production Standards

applicable to every job, every printer, every operator |

|

| |

Integrate new printing

devices to ensure they

match existing printers –

compare to reference and

compare to one another |

|

Benchmark printers,

check for precision

and accuracy |

Monitor printers on

a job / daily basis

(Show weekly reports

per printer/operator) |

Adjust as necessary

to bring into alignment

(G7 Curves / ICC Profiles) –

eliminate dedicated press runs |

|

|

Get printer production under control:

- Define Job Standard applied to every job, every printer, every operator

- Benchmark printers, check for precision and accuracy, understand where the printer is

- Adjust as necessary to bring into alignment (G7 Curves / ICC Profiles) – eliminate dedicated press runs

- Track printers on a job / daily basis (Show weekly reports per printer / operator)

- Integrate new printing devices to ensure they match existing printers – compare to reference and compare to one another

|

|

|

Get substrates under control:

- Define Job Standard

- Benchmark substrates in line with print

- Adjust as necessary to minimize the number of curves, profiles

- Track over time

- Integrate new substrates

|

|

|

Get light booths under control:

- Define standard quality metric – E-Factor or ISO 3664

- Benchmark light booths

- Adjust as necessary

- Track over time to ensure bulbs are valid

- Integrate new light booths

|

|

|

Get displays under control:

- Define standards for tolerancing

- Benchmark displays

- Adjust as necessary

- Track over time

- Integrate new displays

|

|

|

Get environment under control:

- Define standard based on the requirement

- Benchmark room environments

- Adjust as necessary

- Track over time

- Integrate new environments

|

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.