45°/0° Annular Geometry and more

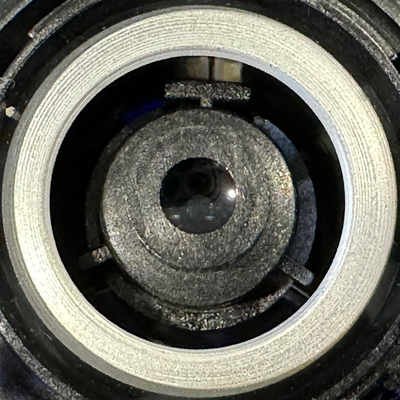

X-Rite i1 Pro 3

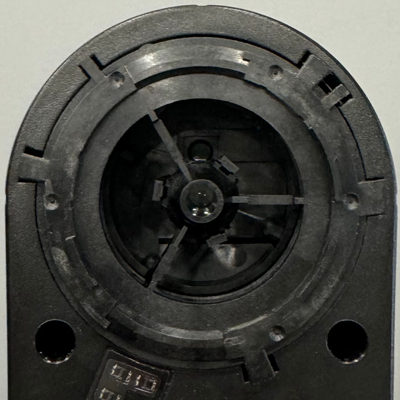

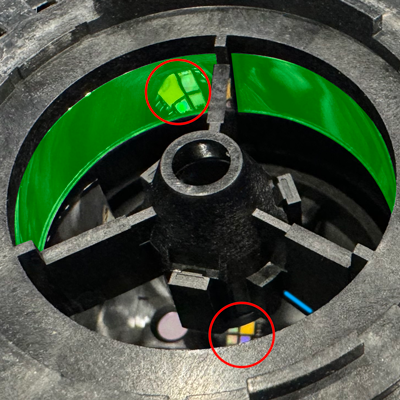

By removing the plastic ring, we can see how the most popular spectrophotometer on the market is constructed. Centrally at the very bottom, we can see a multi-LED module. Combining different LEDs allows you to modulate the spectral light used to illuminate the measured sample, and this allows for flexible spectral adjustment— simulation of illuminants to meet the requirements of various measurement conditions (M0, M1, M2). Above the LED unit, there is a lens suspended on three delicate arms, focusing the observed image on a fiber optic cable, which transfers the received optical signal to another place where there is a sensor analyzing the light spectrum. Halfway up between the LED assembly and the measurement site. there is a mirror ring whose arrangement allows for a precise lighting angle of 45°. Only three small arms interrupt the perfect ring. The result was an almost perfect ring lighting. X-Rite technology marked as "i1" using optical fiber allows the sensor to be physically moved to another place of the device, freeing the structure from problems related to packing components in one place.

X-rite has improved the technology in subsequent editions of this instrument, reaching a very high level for version number 3. The differences between the versions are highly measurable and it is very reasonable for users of old versions to upgrade to version 3.

|

|

|

| In the center, we can see the lens supported by three arms. The multi-LED module is fully covered by the lens. |

The angle view shows the multi-LED module located at the bottom. |

green area - curved mirror upper red circle - a reflection of a multi-LED module lower red circle - a multi-LED module blue line - fiberglass transiting light from lens to sensor |

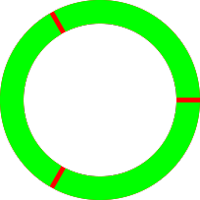

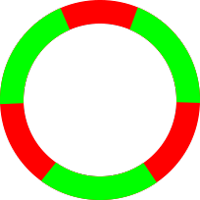

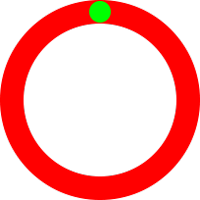

Annular geometry perfection.

|

In theory, three arms cover approximately 4% of the ring's circumference, providing 96% coverage. Arms are located halfway - no sharp shadows - finally, the real impact seems to be unmeasurable. We can classify this annular geometry as 100% efficient. |

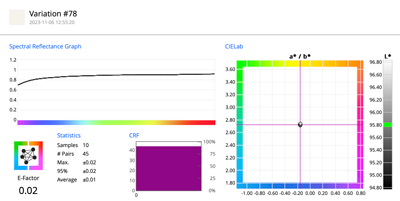

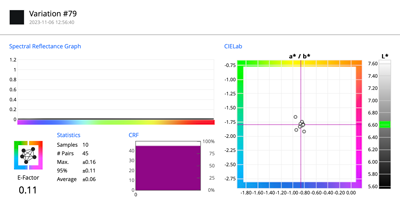

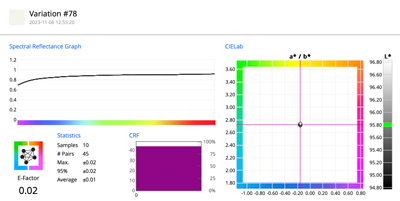

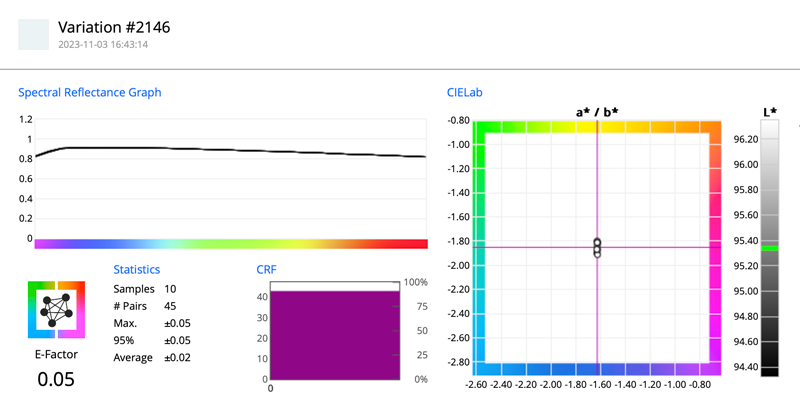

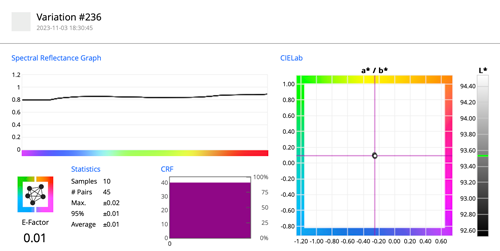

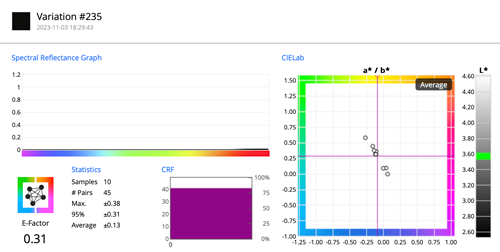

Short-time repeatability

|

|

| In calibration tile! Average error 0.01! | On the black high-glossy sample |

It is surprising how this instrument is repeatable. Test on MediaWedge printed on proofing paper, in 100 repeated tests gives values hard to get from any other popular instruments! That proves brilliant X-Rite engineering and shows why mass production is reflected in product development!

Note

The first 10-measurement test is made on a high glossy deep black sample (similar to piano black) while the second is on proofing paper where the L* value is higher and the surface semi-matt. That makes a difference. Both black sample comes from real word but they are different in nature.

X-Rite i1 Pro 2

The earlier version 2 has a similar construction, but on the bottom, a gas-fille tungsten lamp only is installed. Additional two LEDs stat are adding UV components are located on the additional holder that is breaking the ring stronger. UV light is coming only from one direction ( non-annular, single-point)

|

|

Annular geometry perfection.

|

I1Pro 2 is based on the i1Pro 1 version where additional LEDs have been added. The reason- introducing M1 (D50) measurement conditions data can't be realized using a tungsten lamp only, which is "A" illuminant. |

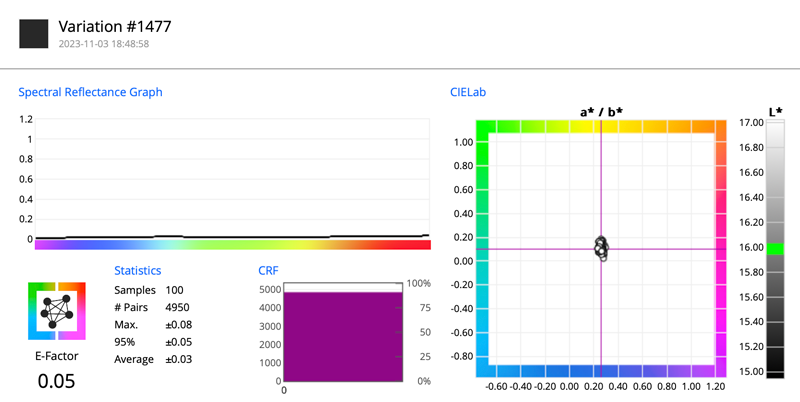

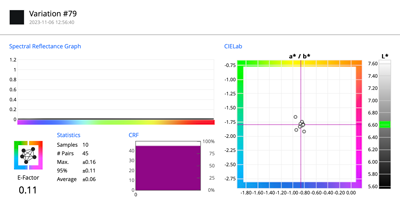

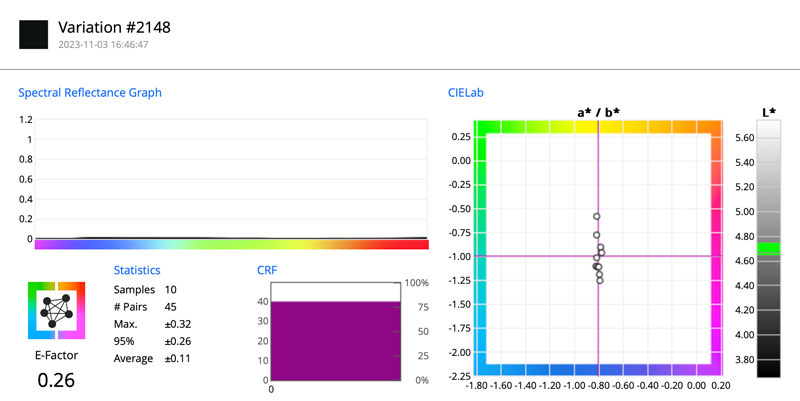

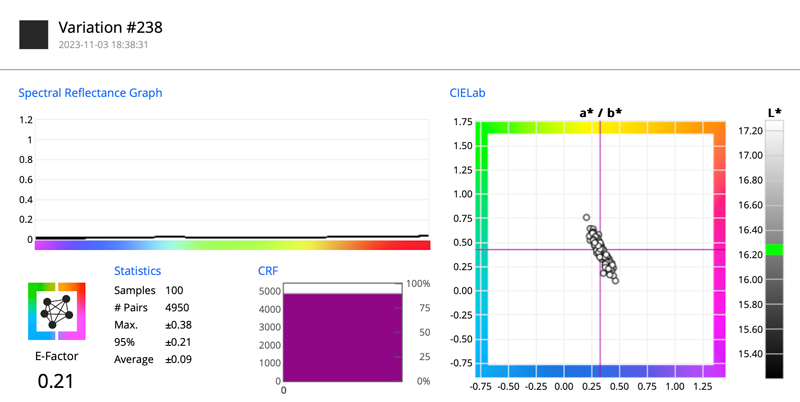

Short-term repeatability.

|

|

| Test on calibration tile gives an average error of 0.01 | The same test on a deep glossy black sample |

Test on black patch from Media Wedge printed on proofing paper and measured 100 times is not bad but not as good as in the case of i1Pro 3 where the result is impressive. The difference is mainly caused by the tungsten lamp used as the main source of light.

The average error is ± 0.09 and the max. error ±0.42 - which means the peak difference in this test is 0.84 — this value is higher than expected and if real accuracy is expected upgrade to version 3 is required.

Seems that the gas-filled tungsten lamp is the weakest element of this solution.

X-rite eXact (v.1)

|

|

|

|

X-Rite eXact v.1 has a series of light sources - tungsten gas-filled lamps and LEDs (UV 375nm and UV 405nm) located at 45% but this is not a ring but a series of few points. In fact, the main source of the light is based on three gas-filled tungsten lamps located every 120 degrees. Visible LEDs emit UV components and make post-measurement calculations to calculate different M-condition data.

Such a solution might be very sensitive to angles - if the sample is not uniform and matt-finished results might be not reliable. This instrument is not designed to measure metallic, pearlescent, or any very complex surfaces. even if it passes ISO specification and geometry is classified as a ring - don't expect that 3-points are equal to a real ring.

Vendor Specification (selection)

Spectral analyzer DRS spectral engine Spectral range 400 nm - 700 nm with 10mm interval

Short-term repeatability - White 0.05 ΔEab (standard deviation) White BCRA (Error compared to mean value of 10 measurements every 5 seconds)

Inter-instrument agreement Average: 0.25 ΔEab, Max: 0.45 ΔEab (for M3: 0.55 ΔEab) (Measurements using X-Rite manufacturing standards at a temperature of 23°C +/- 1°C, 40-60% RH for all measurement modes on 12 BCRA color tiles and a white ceramic reference (D50, 2°))

Gas-filled tungsten (illuminant type A) and UV LED

45°:0° ring illumination optics, ISO 5-4:2009(E)

Notes

- This instrument uses a DRS Spectral engine - this solution uses a spinning filter wheel (that is why we can hear a small engine during measurements). The number of filters in the wheel is limited and data processing is required to get a 10 nm resolution. Also, a spectral range is limited to 400-700 nm

- This instrument compared to for example i1Pro3 has visible lower short-term repeatability, especially when measured on black samples.

- gas-filled tungsten lamp is used as the main source of light.

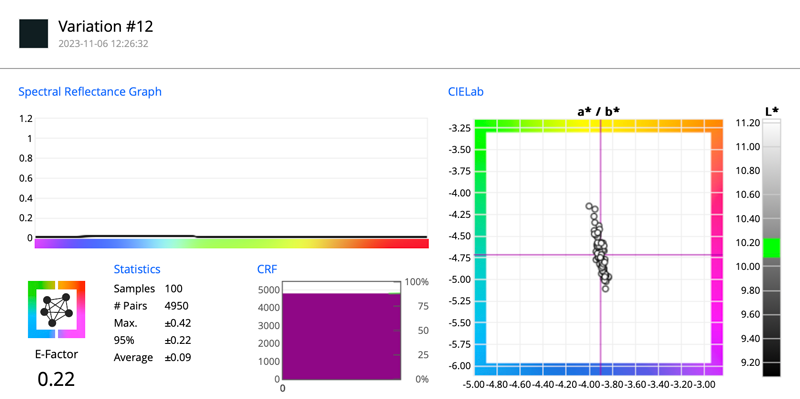

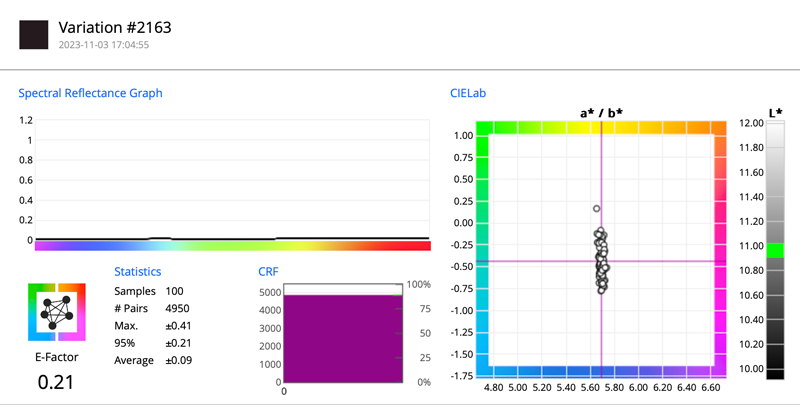

Short-term repeatability

|

|

| Our test for the white calibration tile gave us results exactly as described in the technical specification. | For the black specimen, there is no data published. The repeatability issue is related to the b-axis while the a-axis is very stable. |

We have repeated black sample measurements (Media Wedge printed on proofing paper) 100 times - all measurements triggered from the application (without touching the instrument) to avoid any accidental displacements.

Max error = ±0.41 means that in the worst case, two samples were 0.82 ∆E 00 different. Black samples are critical for G7 evaluation, and it is smart to average data to get more accurate results. This test has been repeated several times using two different units - both in perfect condition.

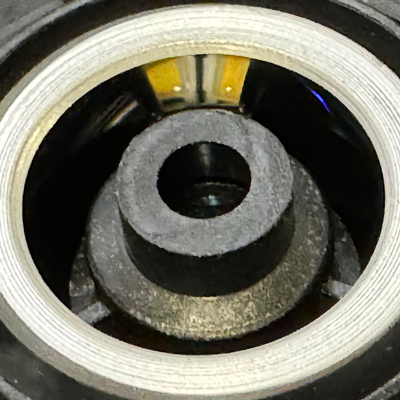

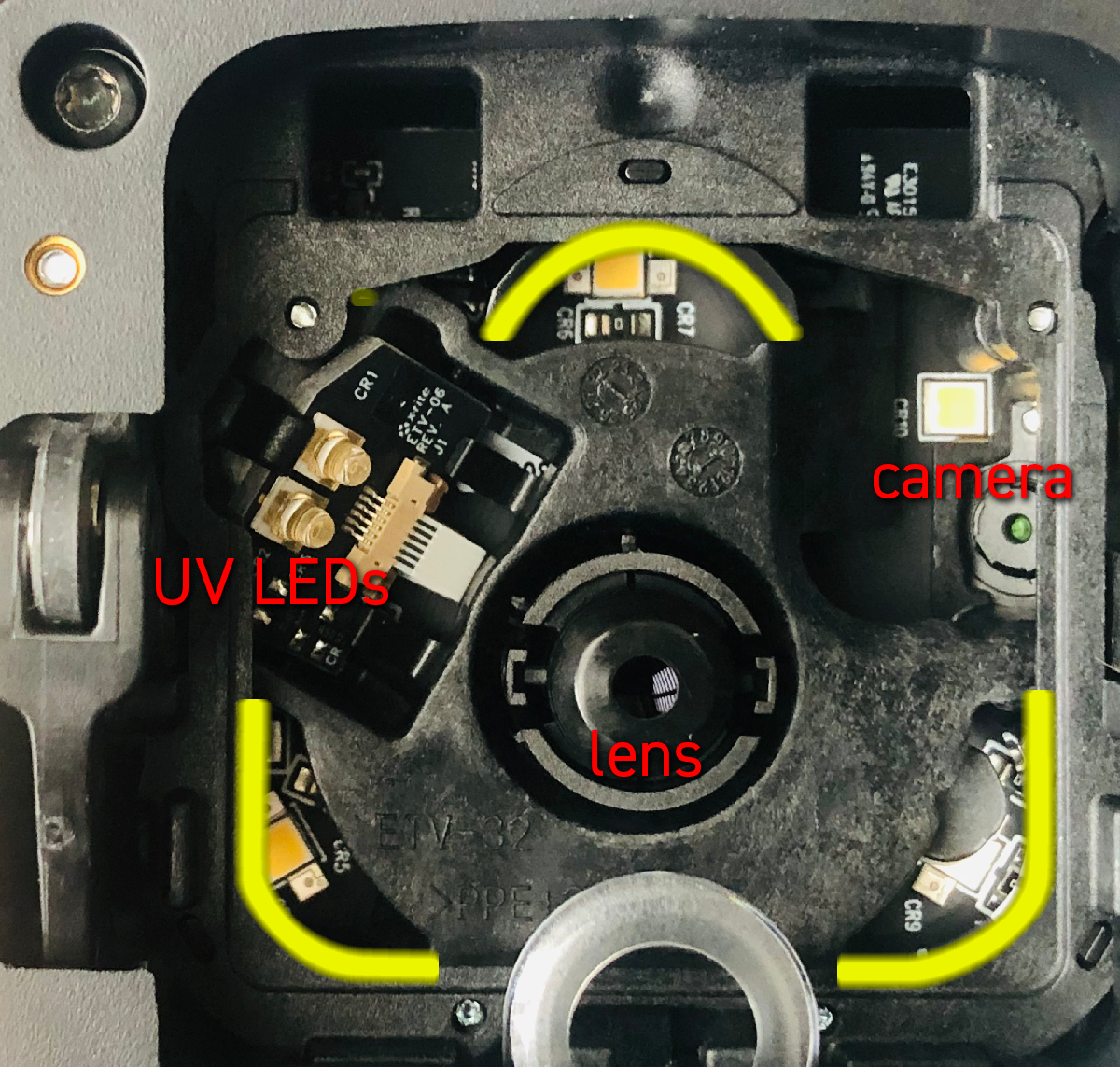

X-rite eXact (v.2)

|

In this case, the complexity of instrument design is a compromise where segments of the ring light the sample. In the picture, we can see a camera with a dedicated LED. |

|

The complex shape of curved mirrors finally produces an illuminating ring (annular 0/45 geometry) thanks to brilliant engineering. The only UV comes from a single direction - but this is precisely what is in the instrument specification. |

Version 2 of eXact has a completely new design. This instrument is dedicated to typical print industry substrates. A sophisticated system of curved mirrors allows for typical paper-based measurements and very good ring reconstruction, but for most complex samples this instrument is not recommended.

Annular geometry perfection

|

A system of three curved mirrors extends three points giving about 50% of the ring in the mirror plane. It produces finally pretty nice ring, however, mirrored rays come still from three single points, and for structural, complex surfaces it is not an equal homogenous mix of all ray angles. This brilliant engineering solution is perfect for matt-finished printed samples on regular paper substrate. Consult the results of our test on brushed polyester film. |

Note:

A system of mirrors is used for visible light only. UV LEDs use single-angle geometry - Whenever a UV component might be critical for the object take into account that no annular geometry is applied.

Calibrate ColorChecker Studio

This instrument has 45°/0° single plane (non-annular) geometry. By definition, it is an angle-sensitive construction. Do not use for any non-matt-finished samples.

|

At a 45° angle single LED is visible. This is NOT annular geometry. |

Short-term repeatability

|

|

| Our test for the white sample shows a very good result! | However, the black sample is less stable. |

Test on Meddia Wedge printed on proofing paper repeated 100 times shows practical errors that can happen when measuring printed samples.

We can observe that errors have trends caused probably by LED used as a source of light.

Note:

This instrument is dedicated for home/office use- it is NOT designed to be used in an industrial environment. Limited to M2 - measurement condition doesn't allow managing of optical brighteners. Ideal for designers and photographers, is also a perfect introduction to spectral measurements.

CC Sphere

This instrument has spherical geometry d/8°. No direct light is illuminating the sample - instead of the ring at 45° white surface of the sphere integrated light from all possible angles. By the definition, the sensor is "observing" the sample at the angle of 8° - that makes this instrument somehow sensitive to some kind of angles that are properties of some objects ( e,g. brushed surfaces). Consult the results of our test on brushed polyester film.

Short term repeatability

Nix Spectro

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.