Velvet, velour type fabrics

In this article, we will investigate measuring color on velvet type fabrics. Fabrics based on weft and warp are almost always not indifferent to direction. The thread determines the angle critical for measuring the color of fabrics. This angle is similar to the appearance of your grass after cut with a mower, depending on which direction the grass was mowed, the color of the grass appears to be a different color, even though it is the same.

This article is useful for anyone who wants to learn about the significant differences between the optical path which determines how spectrophotometers measure color. We attempt to explain the challenges for measuring velvet type fabrics in this article since many people do not realize how the geometry of a spectrophotometer affects the measurement results with these types of samples.

Velour, velvet, and the like...

Velvet is a weft material, i.e., the weft threads are stretched over the warp in the form of loops, and when they are cut, hairs are formed. Velour has an additional warp (the warp is a system of threads that make up the fabric). However, the nap formed on the surface is not perfectly vertical during manufacturing; the fibers lay sideways. If we comb such a surface, the fluff will lie down or stand up depending on the direction with or against the hair. This will significantly change the optical characteristics of the surface and will significantly affect light reflection. Modern velours are most often synthetic materials made of polyester fibers. A single fiber in the microscale is shiny - however, their multitude and the fact that they are not straight makes the surface perceived as strongly matte.

|

|

|

on the right: and close-up view using a microscope (two different types of velvet fabrics, same magnification)

What affects color?

Two surface-specific factors affect the color perception of velvet fabric:

- The same material looks different depending on the lighting and viewing angles, even when the surface is brushed in one direction.

- Combing against the hair direction creates a fuzz and makes the color visibly darker due to the light of instrument getting dispersed in the thicket of fibers and not making it back up to the instrument sensor. (Typical with a 45/0 instrument).

Choose the right instrument and method!

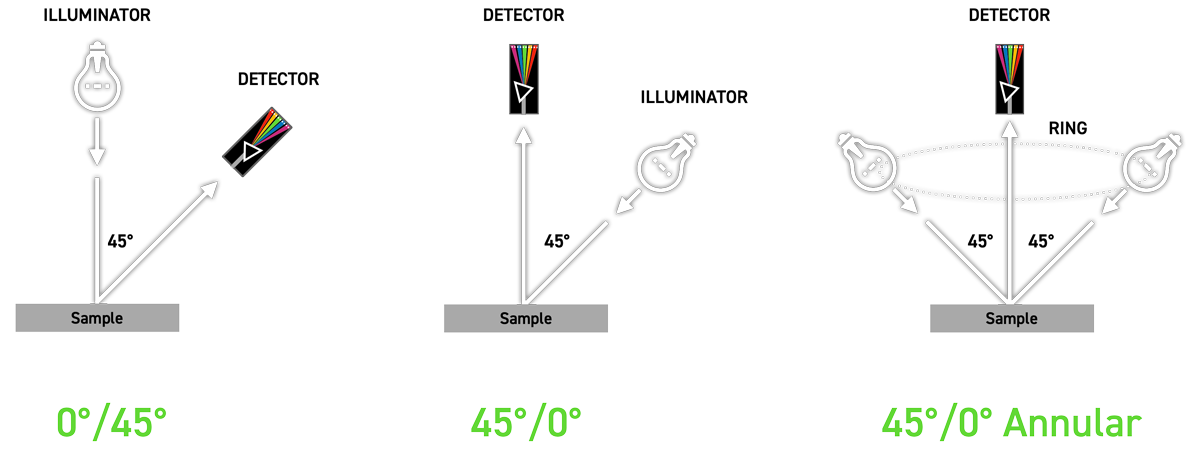

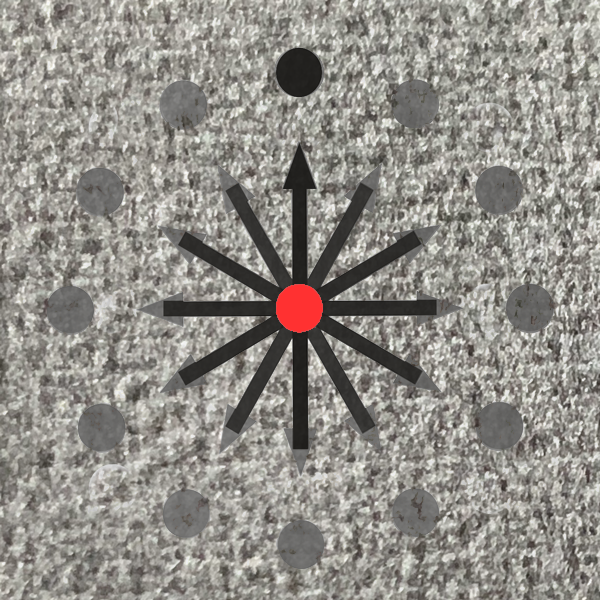

Instrument geometry is a critical component of our test. Read more here. The diagram below helps us understand the problem.

|

|

When measuring objects with angle-sensitive structures, you must consider the observation and lighting angles. Instruments that use the 45/0 geometry always look from above, and the light comes from a 45° angle. But this can cause spotlighting, which is very sensitive to the angle. A better option is to use annular lighting, which surrounds the object with light from all directions. However, not all annular illuminators are the same. Some manufacturers use a few LEDs on a circle and call it annular.

Please note that for the objects described in this article, geometry 0/45° (where light comes from the right angle end sensor is observing from 45° is extremely sensitive on an angle and is NOT recommended, therefore, an instrument like Techkon Spectro Dense is eliminated from this comparison. The human eye perceives large differences when viewing from 45°, which the instrument does not pick up, and there for, there is not good co-relation between the eye and this type of instrument.

Instrument/methods comparison - defining the research.

In his article we compared the results of various instruments during four different tests:

| Test A | Test B | Test C | Test D |

|

|

|

|

|

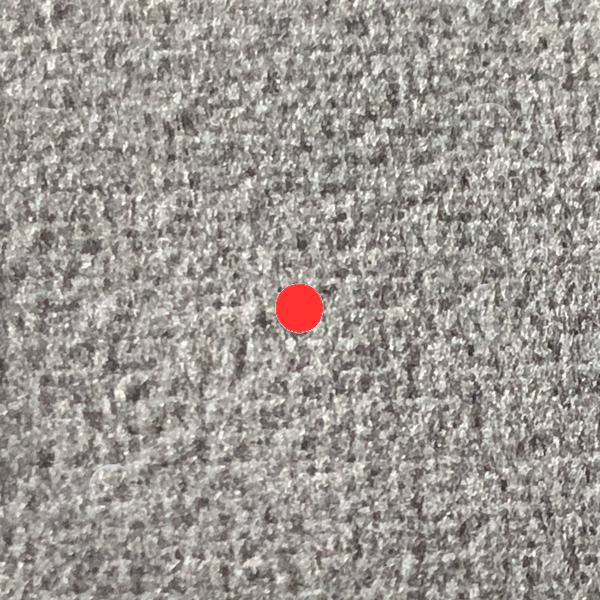

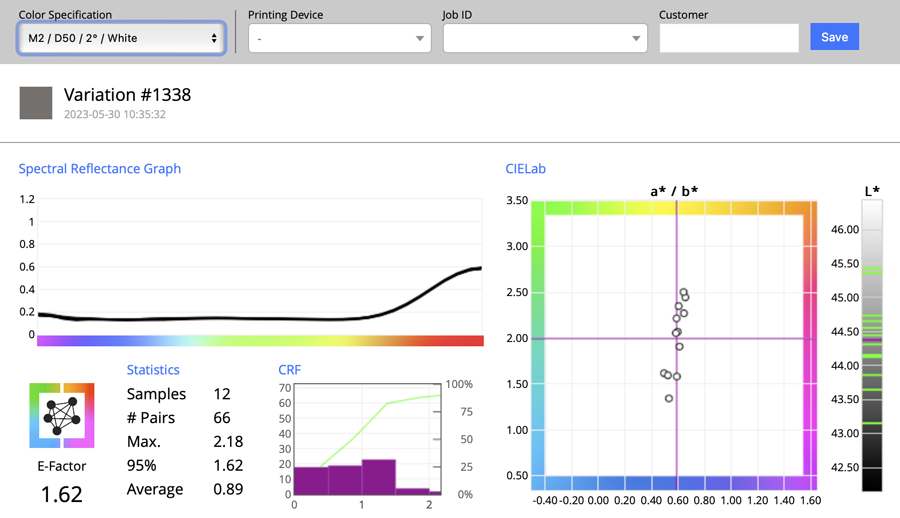

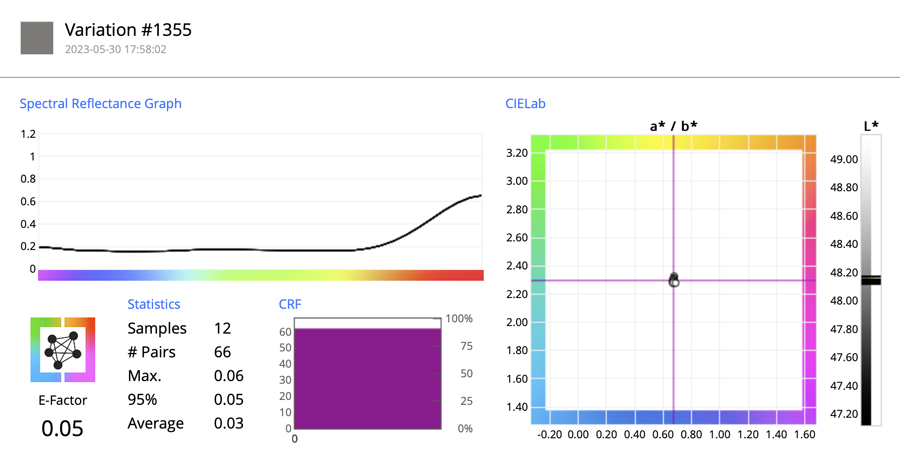

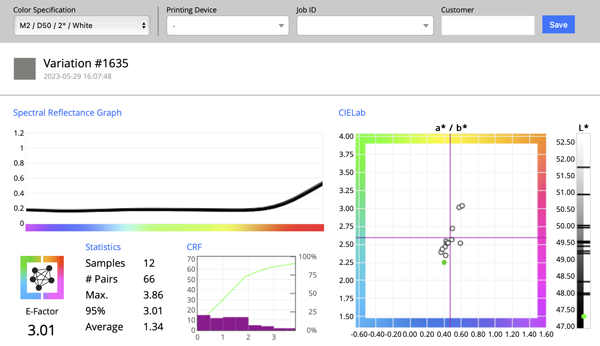

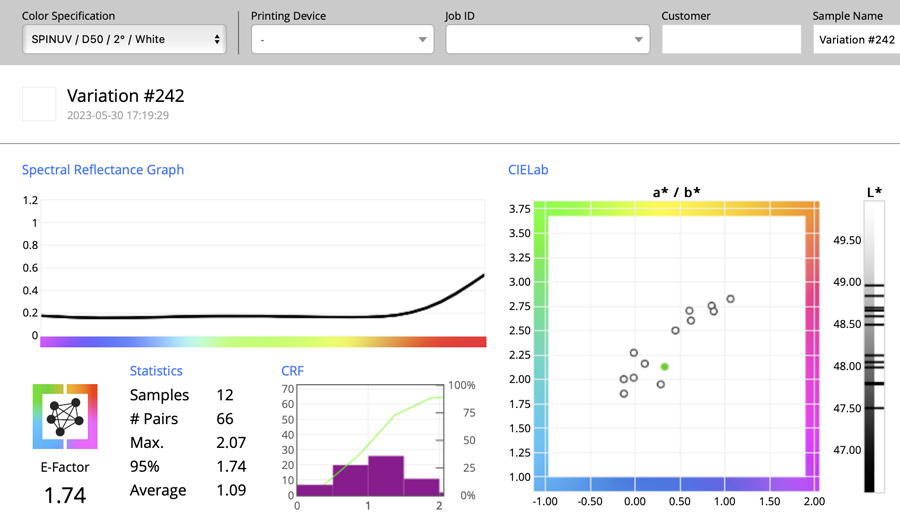

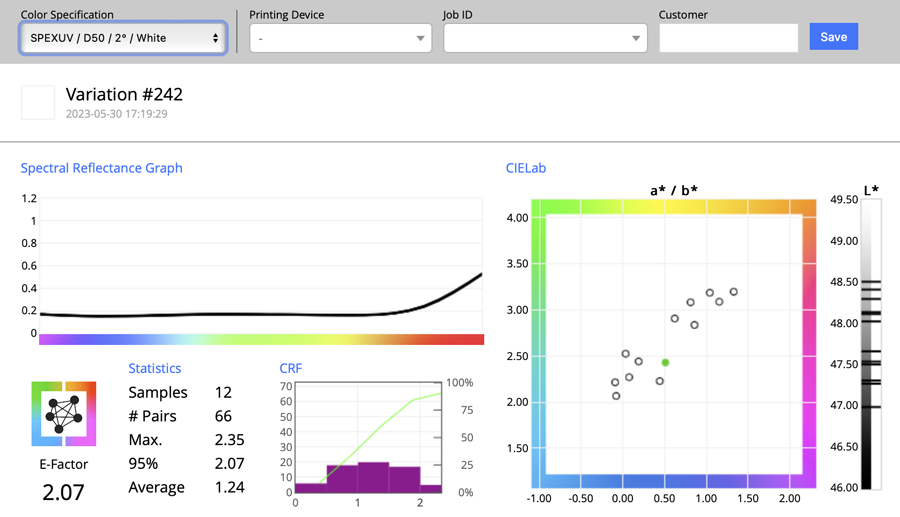

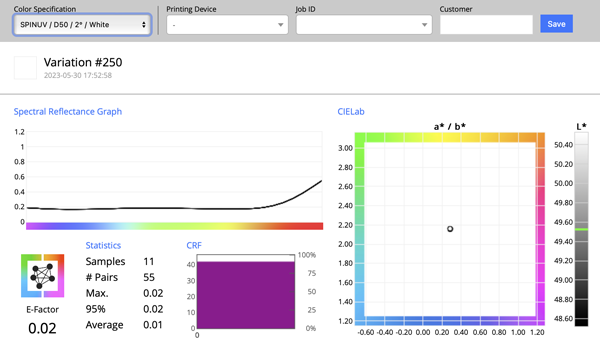

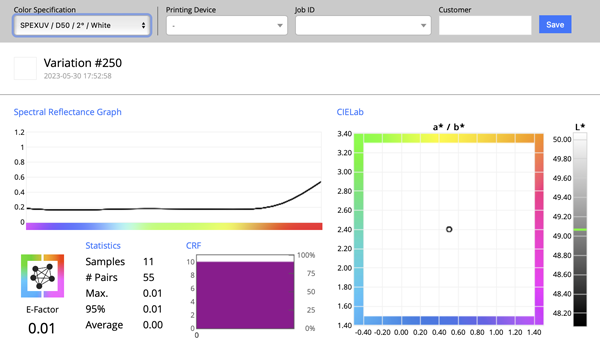

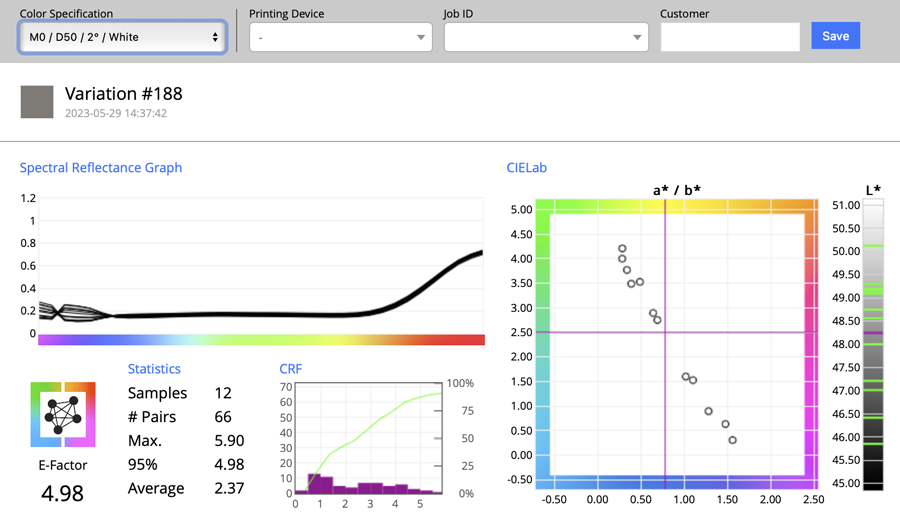

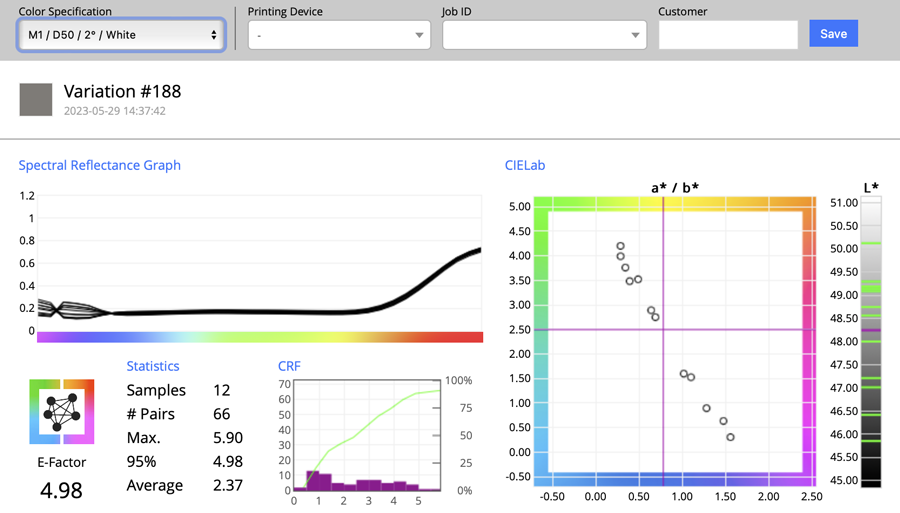

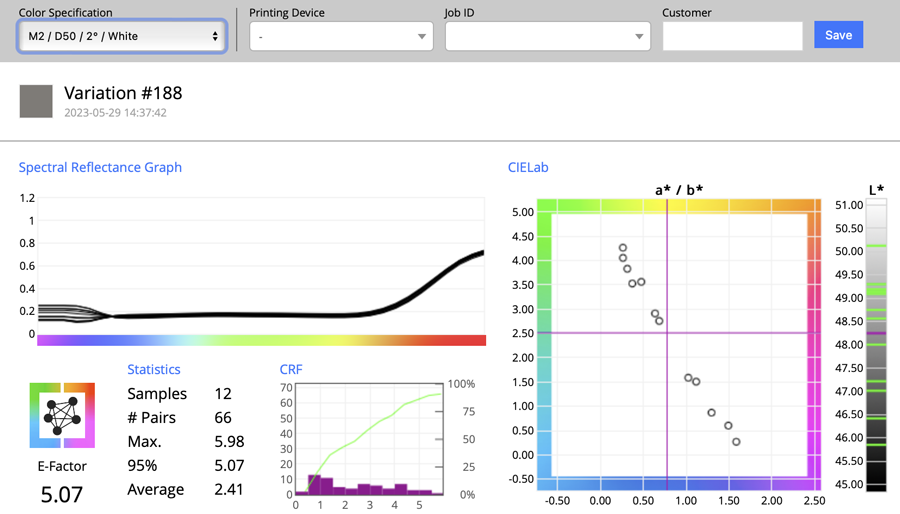

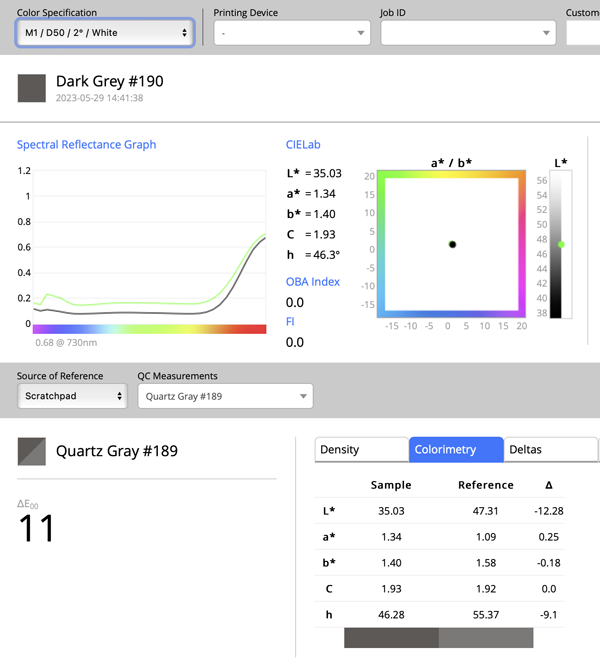

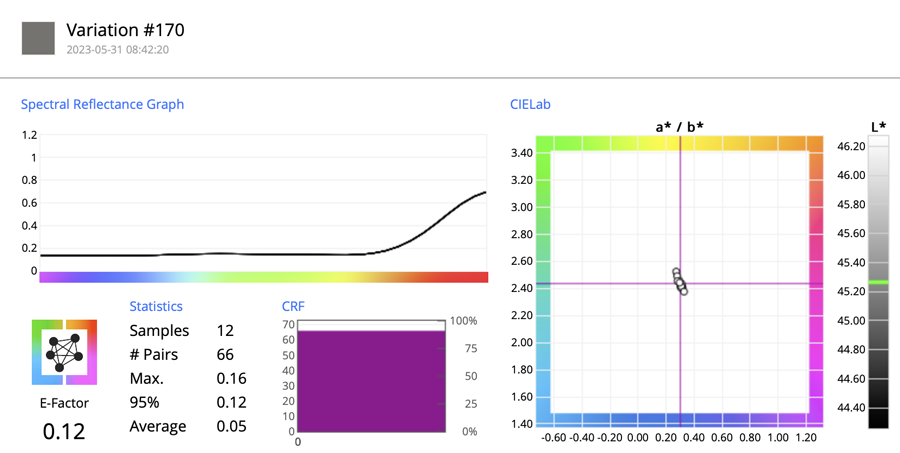

In this test, a single location is measured 12 times in a row without any displacement to see the short term repeatability of the instrument. To avoid micro shifts, a software button from CC Capture is used to remotely trigger measurements. In most cases, the differences are caused not by the sensor, but by the light source illuminating the specimen. Voltage stability, temperature, and other parameters may have some effect on data repeatability. This test shows how repeatable the instrument is. |

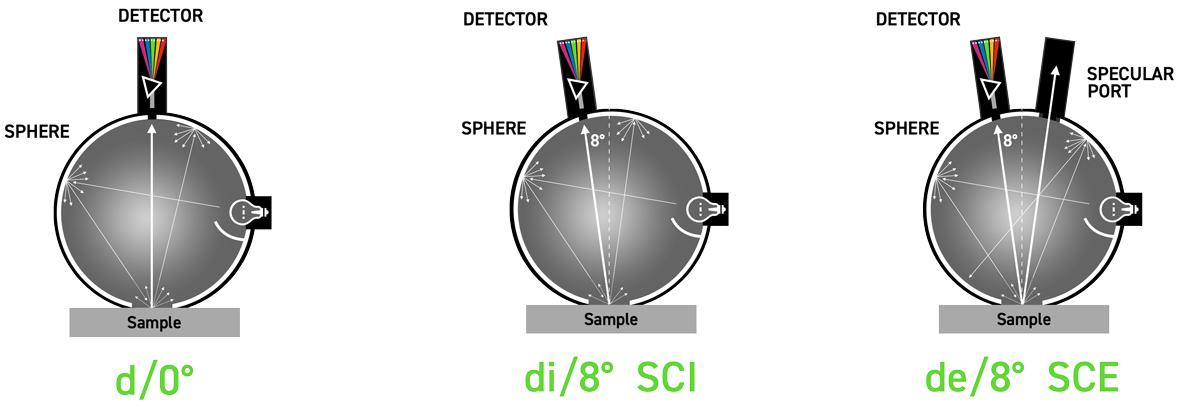

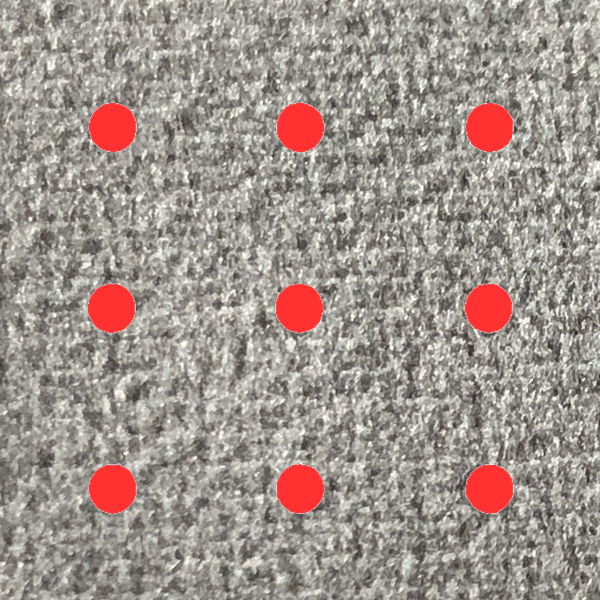

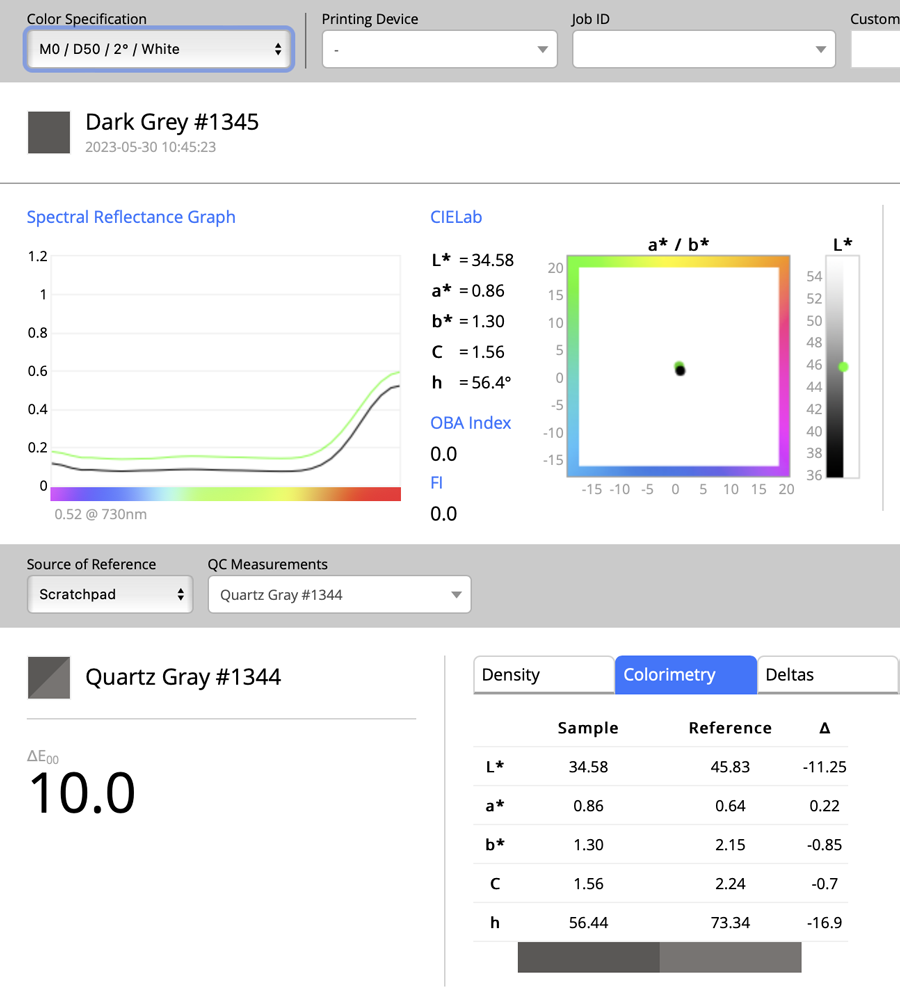

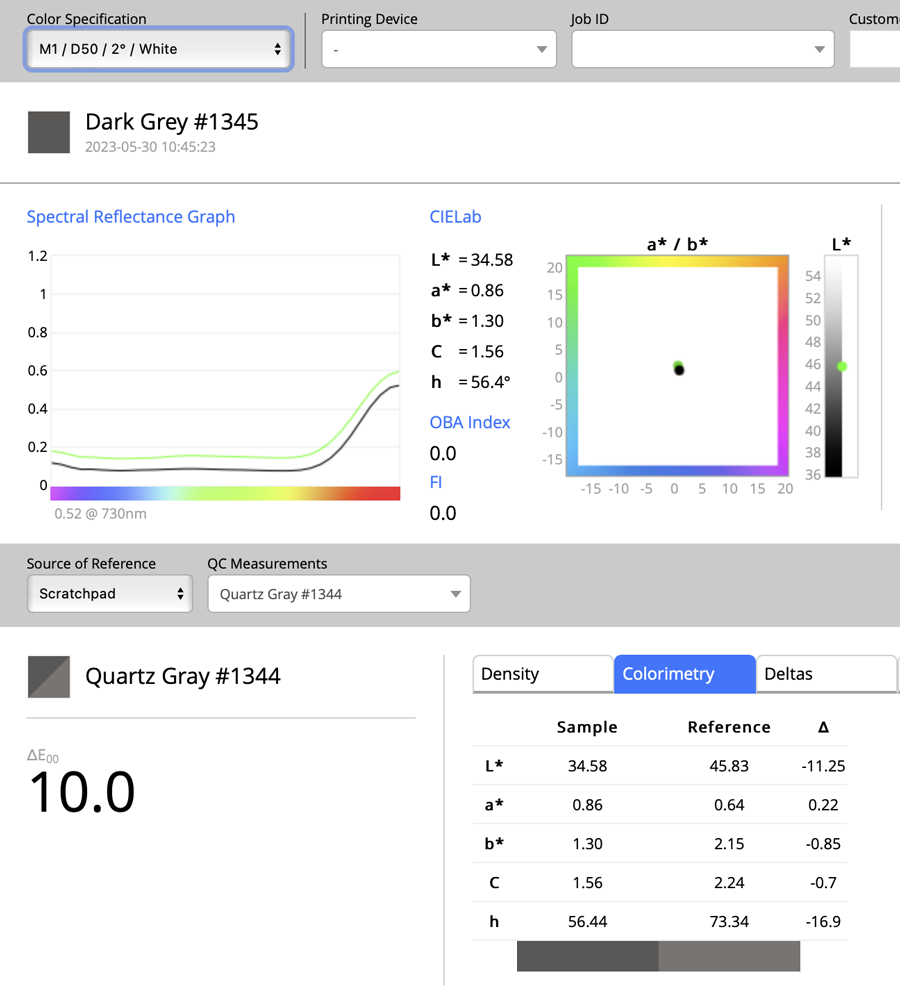

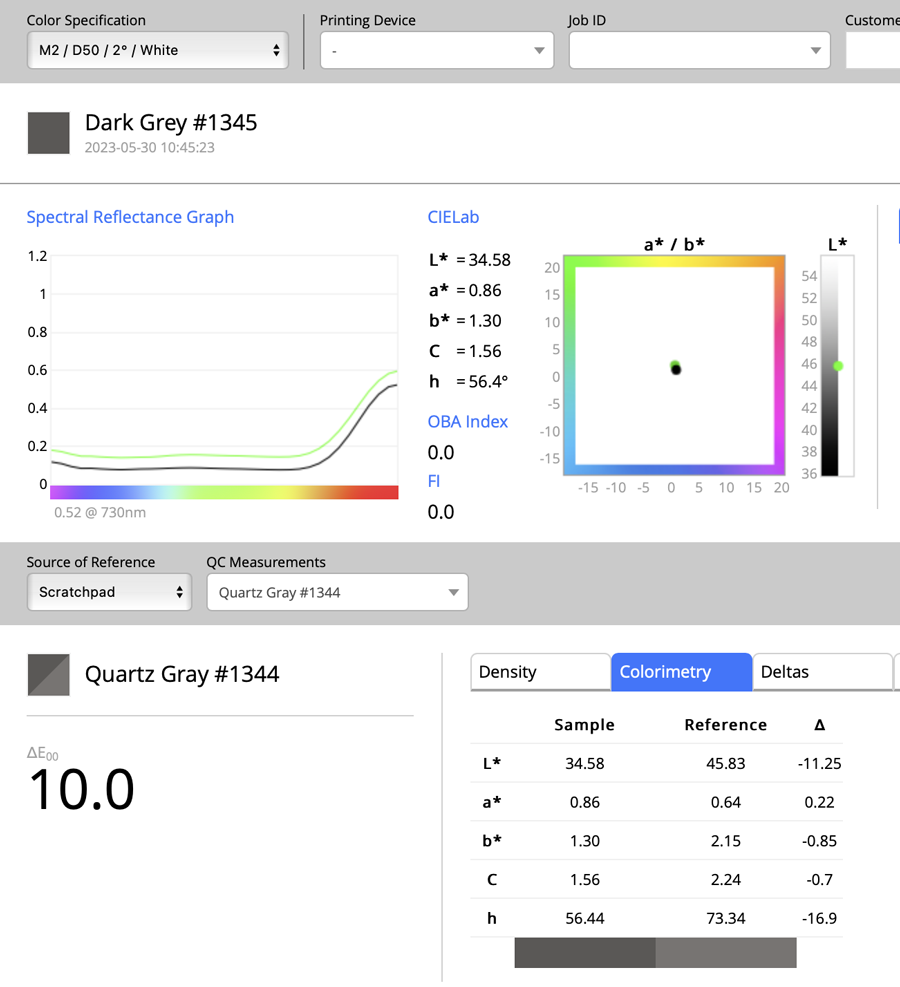

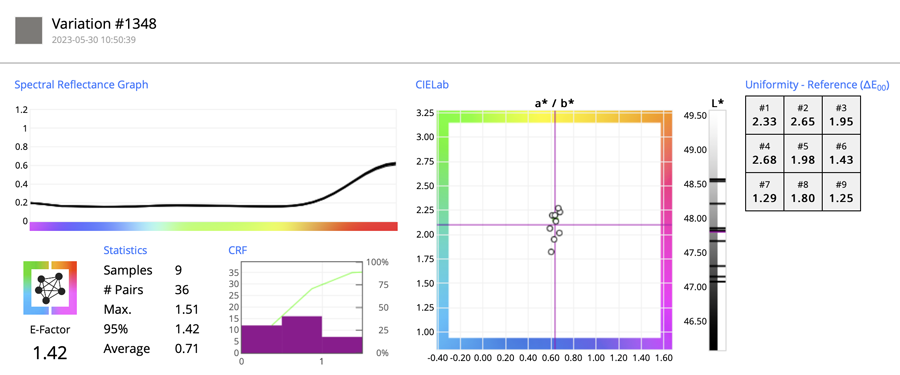

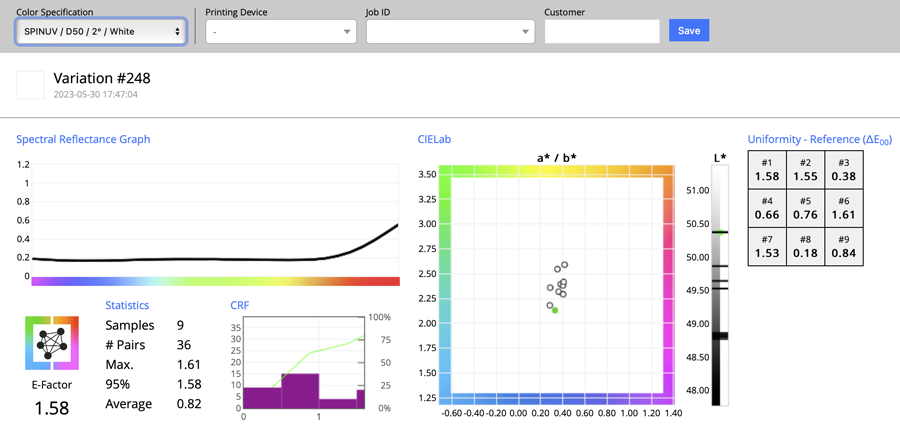

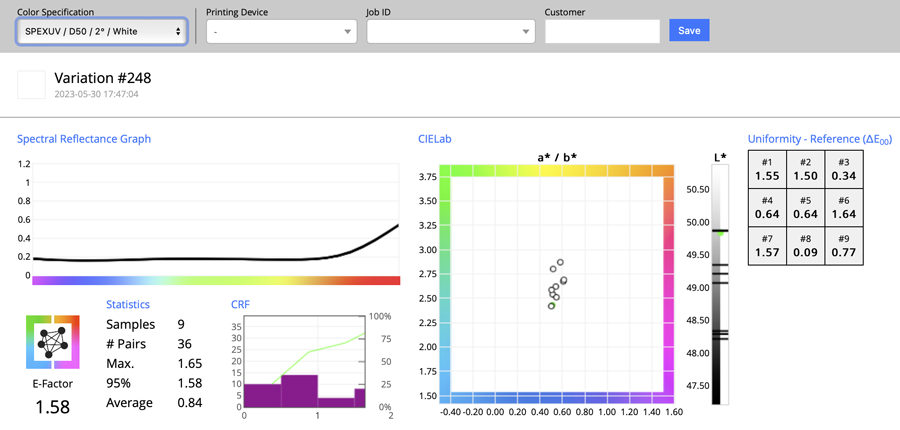

The purpose of this test is to check the natural non-uniformity of the object that is caused by a randomly created surface. In this test, the instrument is positioned into nine different locations. The offset is about half an inch. Whenever we are doing tests we should not expect zero difference as every measurement targets another part of the specimen. |

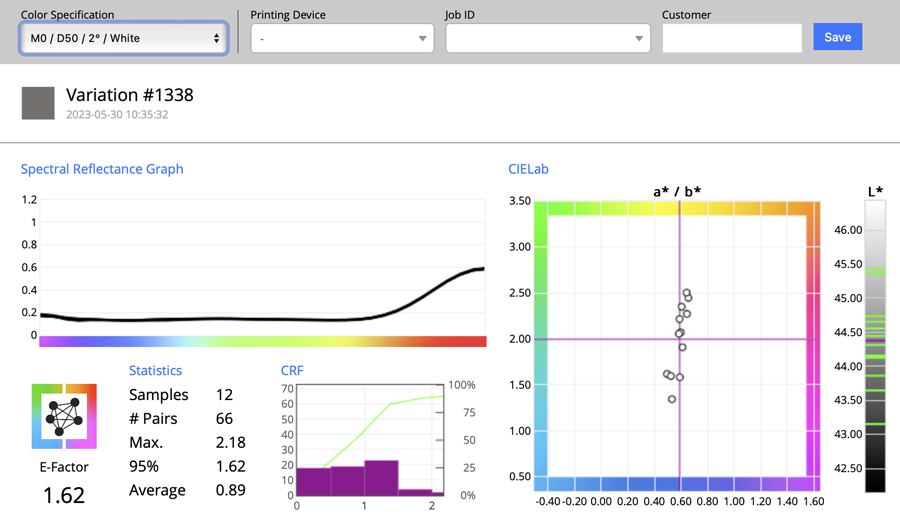

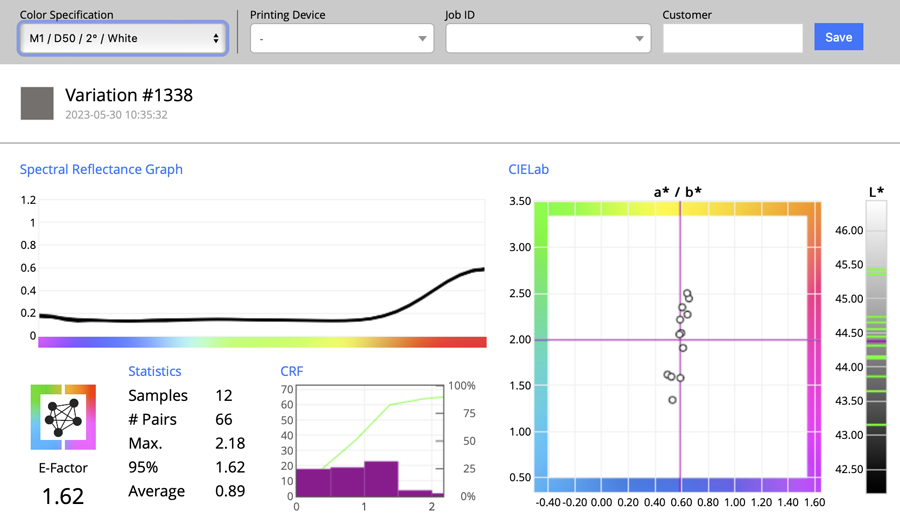

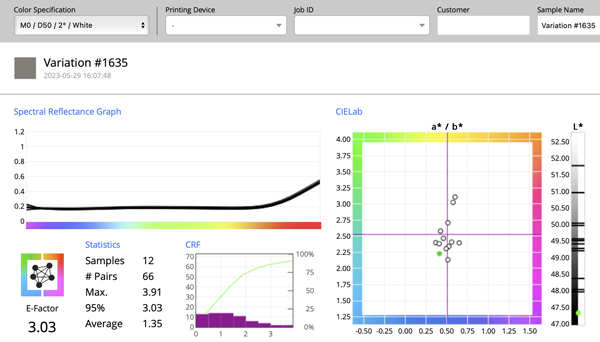

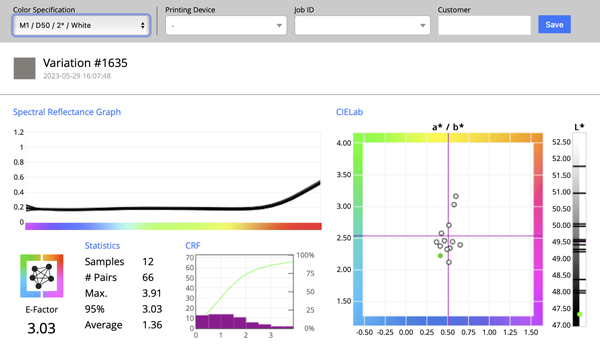

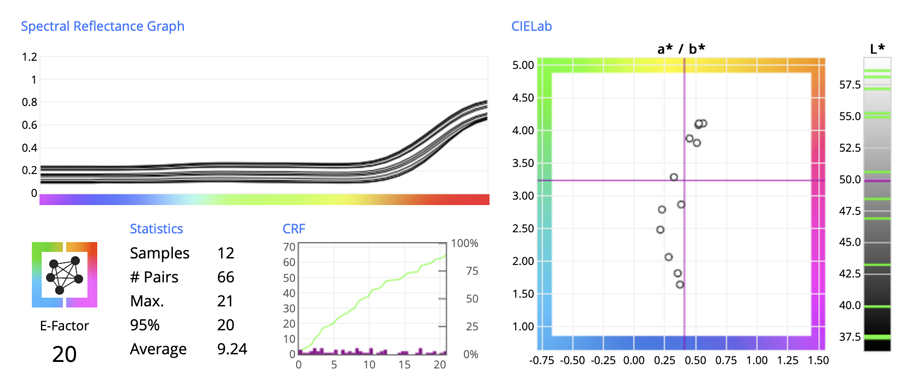

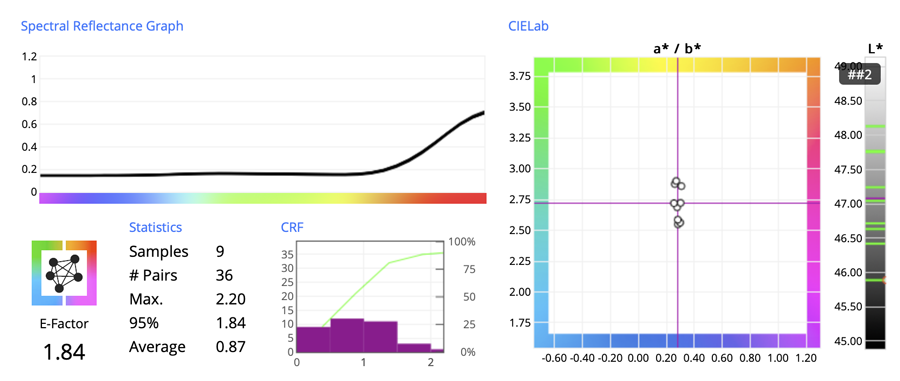

In this test, the fabric surface is combed in its natural direction. The only thing we will change is the rotation of the instrument. Using the QuickChecker Start Variation tool, we measure 12 times using instrument rotated in 30° steps. Variation tool simultaneously reports 12 spectral curves and analyzes statistics for the distribution. Start Variation tool makes it possible to compare a series of measurements to themselves, variation analysts compare all unique pairs (12 measurements, computes to 66 unique pairs). E-Factor for 66 samples eliminates three worse pairs (95% percentile) and shows that 95% of the pairs are within the reported E-Factor delta E. |

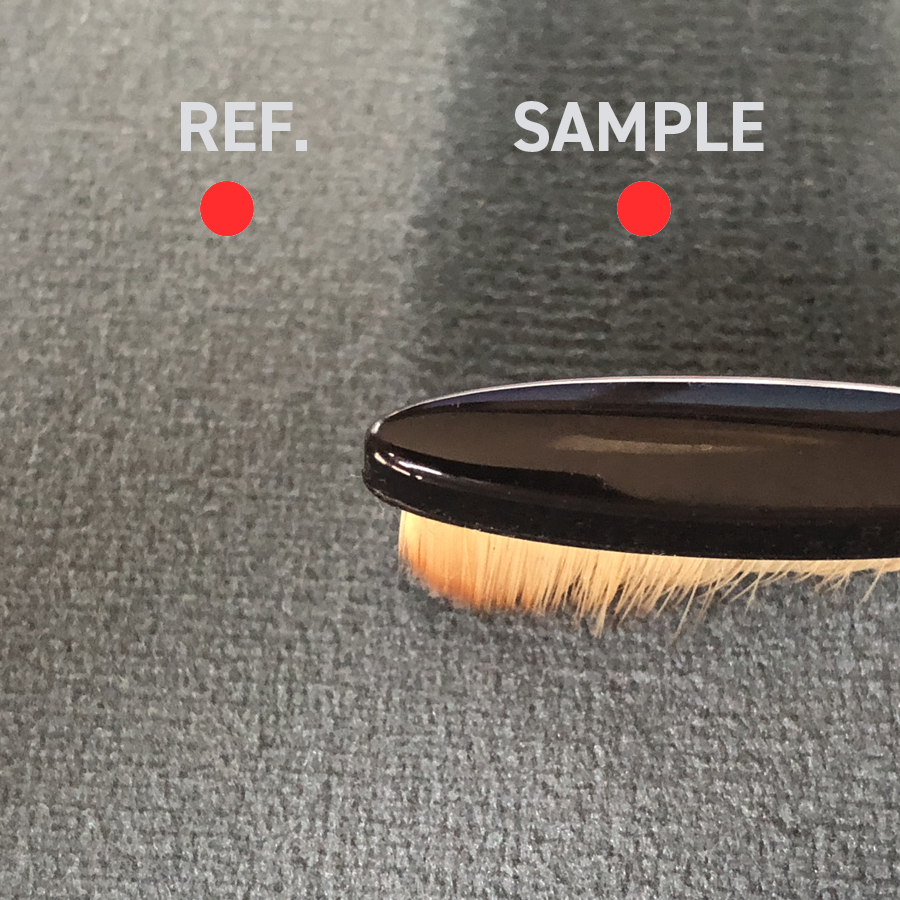

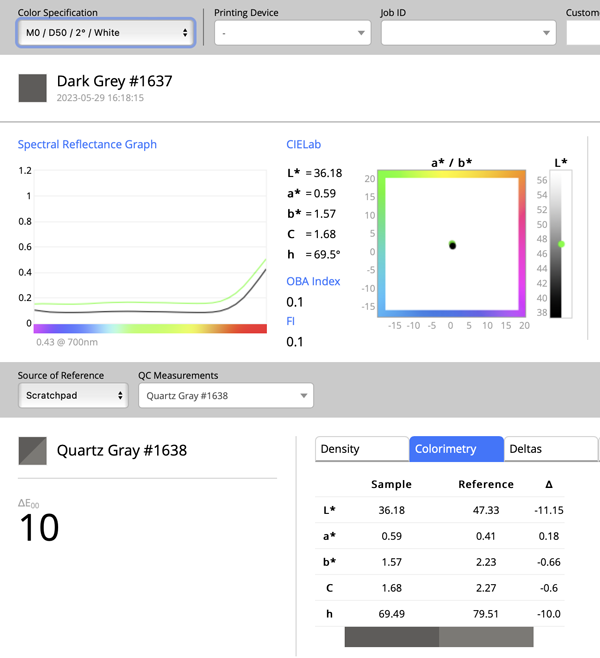

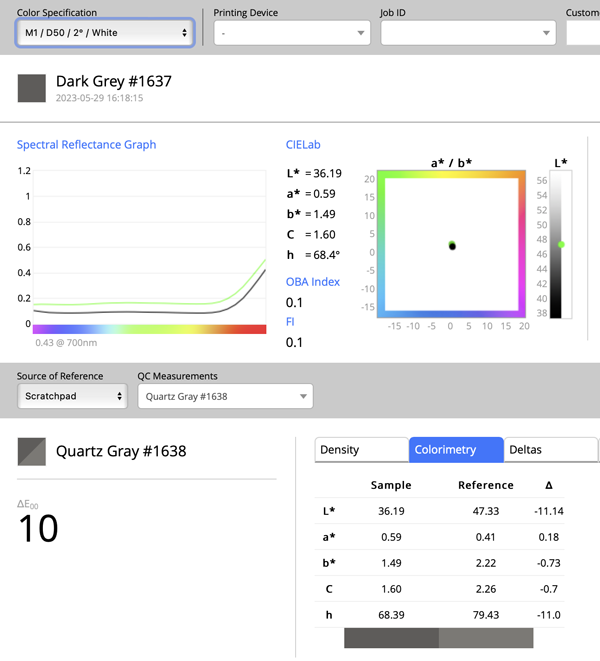

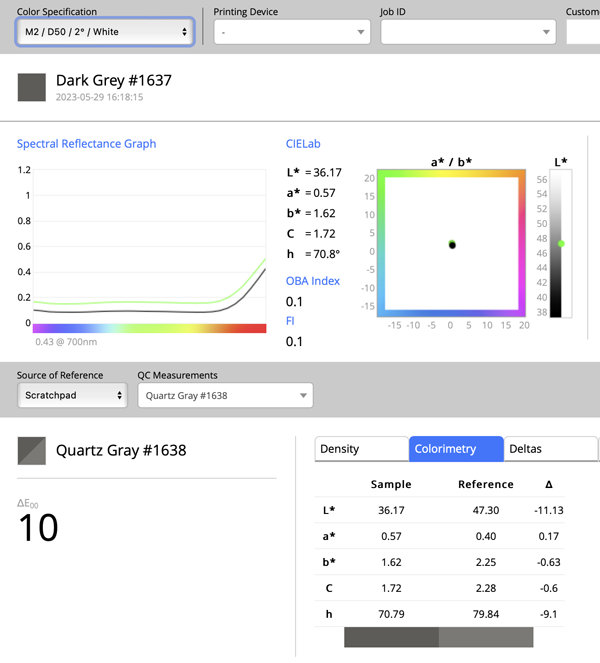

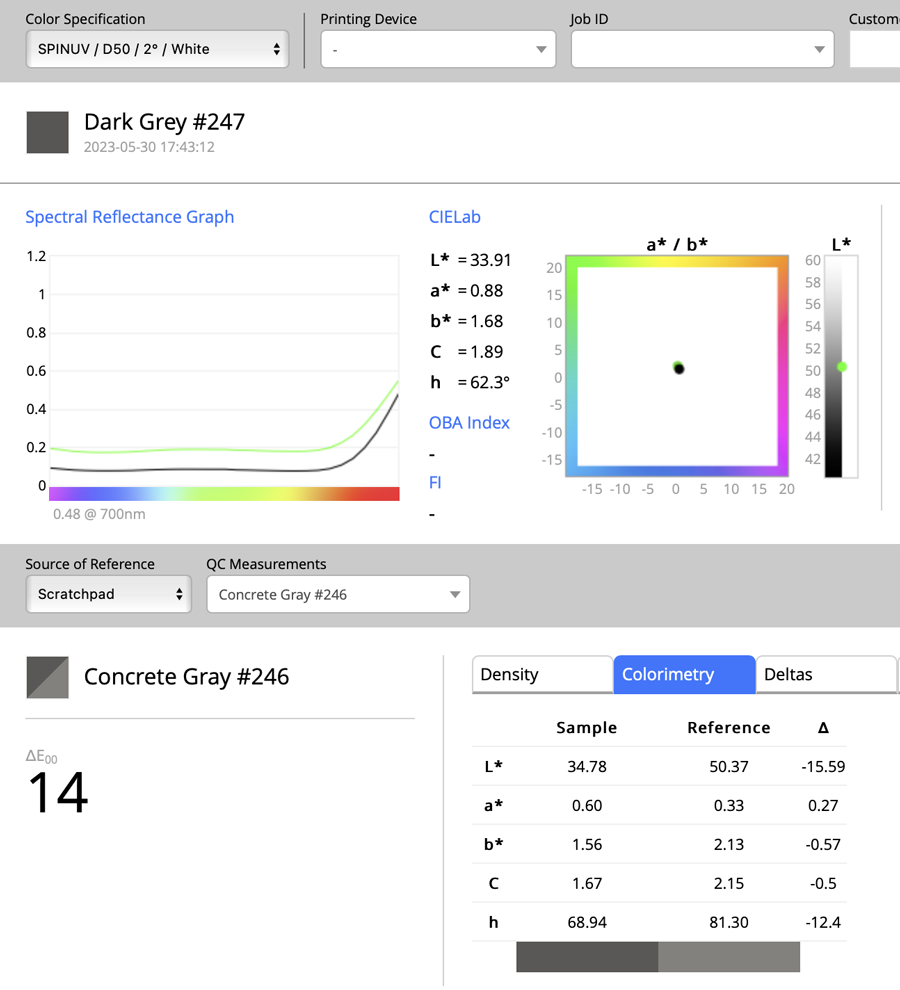

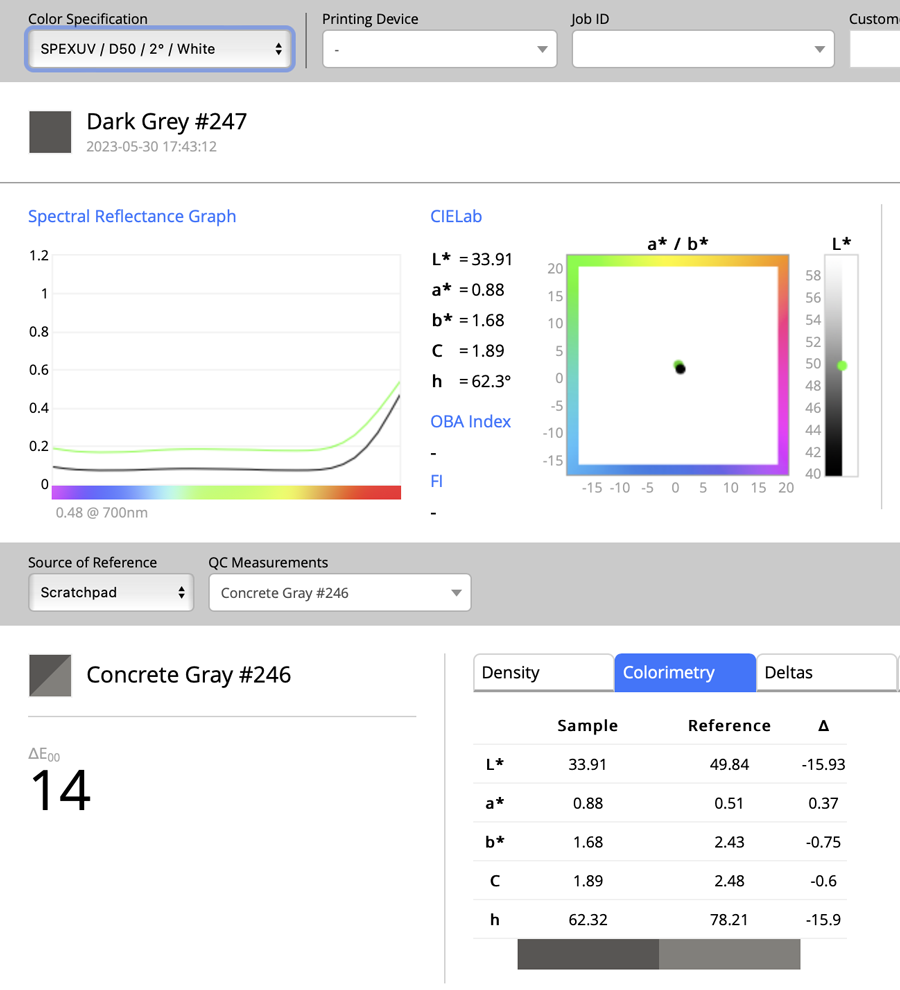

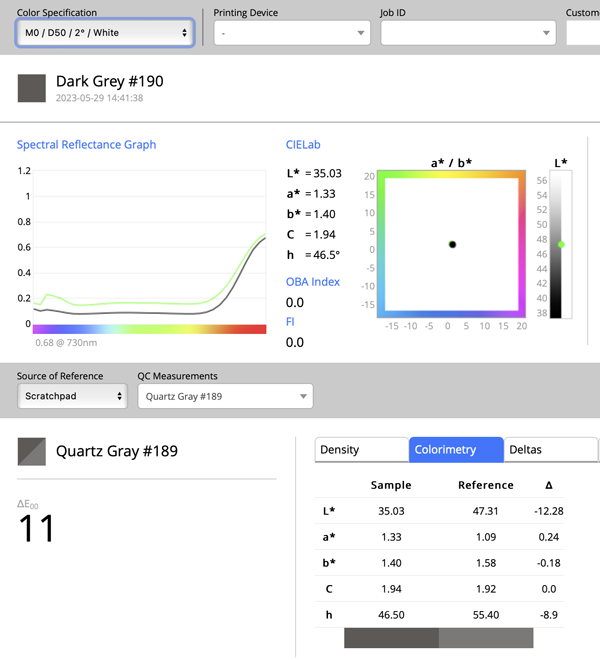

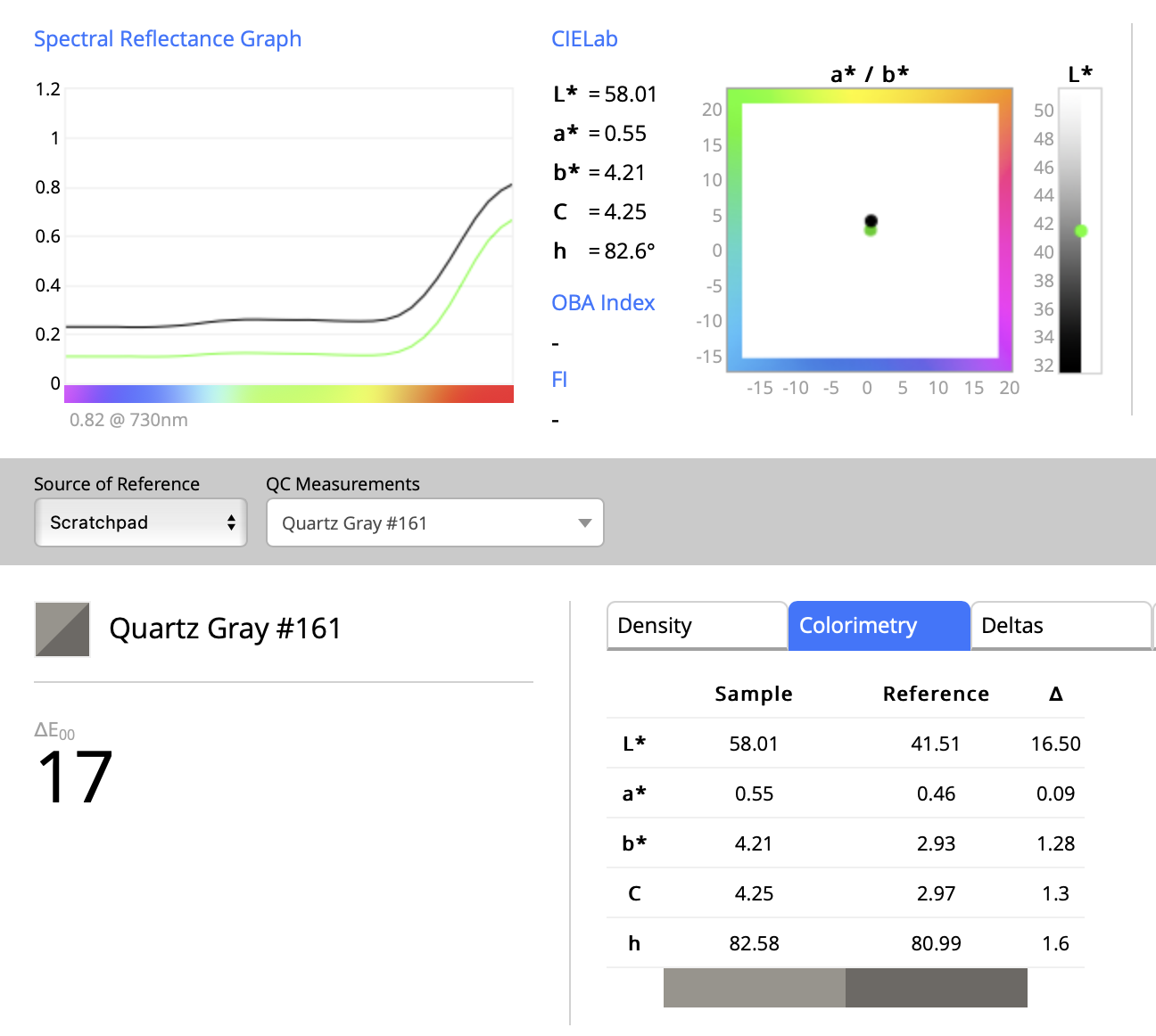

In this test, we will not rotate the instrument. A small brush applied to comb against hair direction makes the right side darker then the left one. We measure the color difference between combing the fabric surface in its natural direction versus against it. We use the first measurement as a reference and the second one as a sample to quantify the difference. |

Important note.

We strongly recommend reading the dedicated articles to help you understand the variance stats. Most users may think that the variants are more significant than they are because, for example, the maximum value expresses the distance between two extreme measurements - not the distance from the center, which may be the average value. For a very even distribution, this value can be doubled - it's like comparing the radius of a circle with its diameter.

X-Rite i1Pro 3

This instrument has an aperture not recommended for textiles - we recommend i1Pro3 Plus. Again thanks to the monochromatic and uniform specimen small aperture for this test is not a big problem.

Test C

|

|

|

Test D

|

|

|

Test B

Test A

X-Rite eXact (2mm)

A 2 mm aperture is too small for most textiles! It is not recommended to use this instrument in any production workflow. We are doing this test for comparison purposes, and we have selected a visually uniform specimen to reduce potential issues caused by a small aperture.

Test A

|

|

|

Test B

|

|

|

CC Sphere (DS-700D)

D/8° geometry handles very effective shining, high-glossy objects; however, the Detector uses an 8° angle - and therefore instrument is partially sensitive to the direction. To learn more, read this document describing a similar case.

Test A

|

|

Test B

|

|

Test C

|

|

Test D

|

|

Conclusions for CC Sphere

CC Sphere uses patented technology where the second spectral sensor is used for compensating fluctuations in the source of the light. The benefit of this second sensor reveals itself in test D where delta values are extremely low proving the stability and consistency of this approach. Based on all our tests this instrument is absolutely the best in this category. We have repeated this test on various surfaces with 100+ repeats and no other instrument can get this level of consistent results.

Myiro-1

Test A

|

|

|

Test B

|

|

|

Test C

Test D

ColorChecker Studio (M2 only)

Test A

Test B

Test C

Test D

ColorChecker Studio conclusions.

Regular, non-annular 45°/o geometry can be applied for matt printed paper. Still, not for complex uni-directional surfaces, textiles, and anywhere we see that angle has an impact (also read: Brushed metallic surfaces).

General conclusions

- Fabric thread angles are very important and can affect the outcome significantly. For any evaluation, the method has to standardize it.

- Instruments are different and select the one which is lowly sensitive to angles - spherical instruments or with the high-quality annular illuminator. Instruments based on 45°/0 geometry or using single or few-point-based illuminators are much may produce varied higher than expected.

- Each measurement leaves an imprint on the surface. for the next attempt, it has to be combed.

That shows that for some specimens we need to have a repetitive method to prepare the surface.

- All instruments on the market have some pros and cons - but for a given task, some are better. We strongly recommend to perform dedicated tests as the best method to find the best solution. Sometimes hi-end instrument is designed for different kind of objects and less advanced instruments may work better.

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.