Printing on KM-1e with ChromaChecker LUTs

Manufacturing Chromaspot or other color fan books requires an accurate and precise printing device. The Konika Minolta KM-1e is a very good example of a printing device that offers great precision and accuracy and prints on various substrates at relatively high production speeds. Additionally, it is equipped with flexible software with a straightforward user interface.

With KM-1e, custom color fan books can be printed with great precision. The printer comes with Myiro-9 (FD-9) which when paired with ChromaChecker Capture's Color Match Scan provides an excellent automated solution to automatically match thousands of colors with minimal effort and little time.

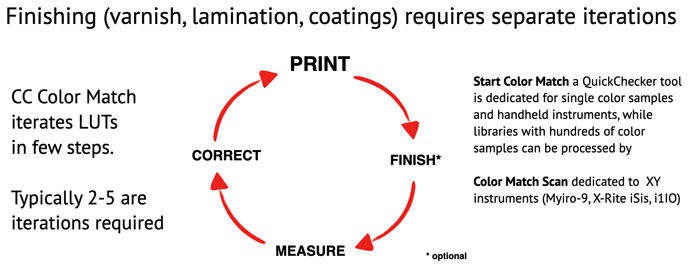

Color matching can be extended to any postproduction device which affects color, like a laminator or varnishing unit. The solution enables the calculation of correction to any postproduction process used in the graphic industry and offers exceptionally high precision and speed.

Starting from scratch, calibrating, profiling, and tuning LUTs for the library, which contains thousands of color samples, will take about an hour. Workflows with postproduction need additional time for additional processes, of course.

The described procedure can be used with other printing devices, but we are using the KM1 for this example.

1. Paper setup - this includes calibration and profile generation, takes about 30 minutes and is a required step, usually it is created one time for the given paper. The profile defines the print condition of the device and paper when it was made, but all printers drift over time making the profile less accurate. However, CC Color Match Scan function works on the last version of LUT and iterates it if required, so there is no need to update the ICC Profile for named colors or Fan book production.

2. Creating LUTs for the first time.

Require: CC Capture Color Match Scan + Myiro9 or other supported instrument

Simple procedure :

For Myiro -9, scanning a single page with 400 samples takes a few minutes. If we start with a good-quality ICC profile, we must repeat this procedure 3-6 times, depending on the expected accuracy. The iteration may take 20-30 minutes without optional lamination or varnishing.

3. Updating LUTs. This is required if we have existing LUTs and decide to update them to improve accuracy weeks or months after the last usage. We must understand that the printing process can drift due to environmental changes, mechanical exploitation, consumables, and other factors, and periodical iteration is required. Such a procedure typically can take about 10 minutes.

Various workflow scenarios.

There are two basic ways to work with LUTs. Depending on the goal, they can be applied in ChromaChecker software or the printer's RIP. Both methods have pros and cons, so it is important to understand the limitations of both.

1. Fan book creation

Most RIPs on the market can't process a single job with an unlimited number of named (spot) colors. In the case of KM-1e, this limit is set to 148, which is very high compared to other solutions on the market. That means the printer can't use a single page with hundreds of unique spot colors - no way to print ChromaSpot or most of any other Fan books based on name colors. KM-1e can work with thousands of colors in a single LUT but not use all in a single job. Splitting into separate pages might be a solution, but applying LUTs in ChromaChecker software is much easier than using CMYK color space to address samples in the PDF. Such a solution requires the printer workflow to switch off the Target Profile and use the whole gamut Printer Profile. Typically, the Reference Profile has a smaller gamut, and using it will reduce the effective printable color range.

ChromaChecker Software KM-1e with Target device-link profile disabled

LUT (Name color CMYK values) > CMYK PDF > full-gamut printing based on CMYK data from PDF

An additional advantage in the case of Fan book generations comes from the additional feature of printing actual deltas next to each sample, which is measured during the last iteration.

The same methodology can be applied to Snowflake and Variator files generated by ChromaChecker - the only way to simulate sample variants. In spot mode (named color mode), variants are not iterated and, due to these limitations, can't be precisely controlled.

2. Regular production with spot color library iterated LUTs

This is a typical scenario for everyday production when we can take advantage of iterated spot color libraries.

ChromaChecker can export LUTs to a file format supported by KM-1e. That means it can be easily applied in the standard production workflow to improve named color rendering on any custom print condition, including substrate and optional postproduction finishing. Suppose we prepare a dedicated LUT for a given substrate /postproduction finishing process. In that case, we can be sure that the final laminated or varnished product will match the color standard with high precision. The operator no longer needs to correct critical named colors manually.

In this case, the software uses Named Colors in the PDF, and KM-1e reads actual CMYK values from the assigned LUT.

How do you set up a policy for Color Management?

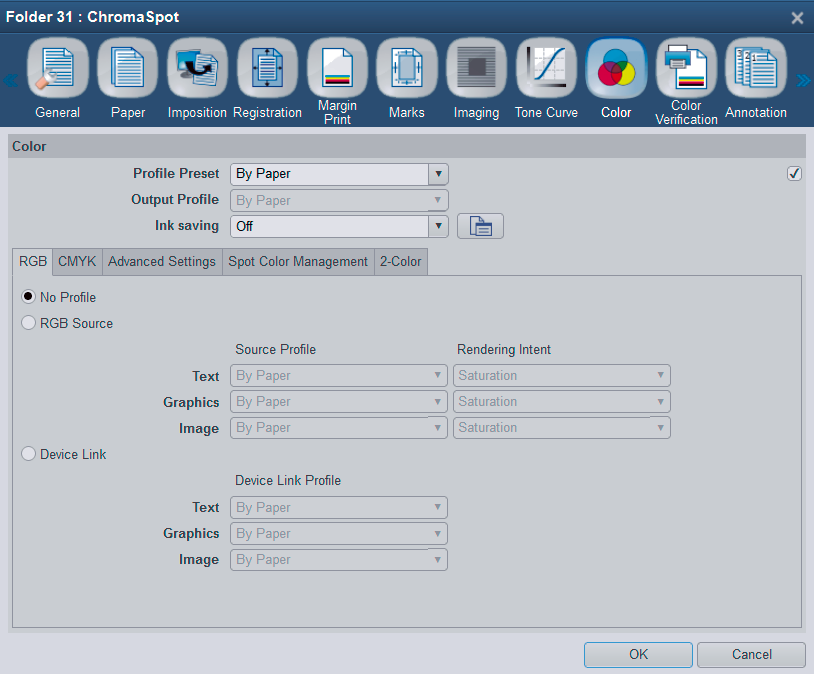

Policy for RGB profiles can be defined in the RGB tab:

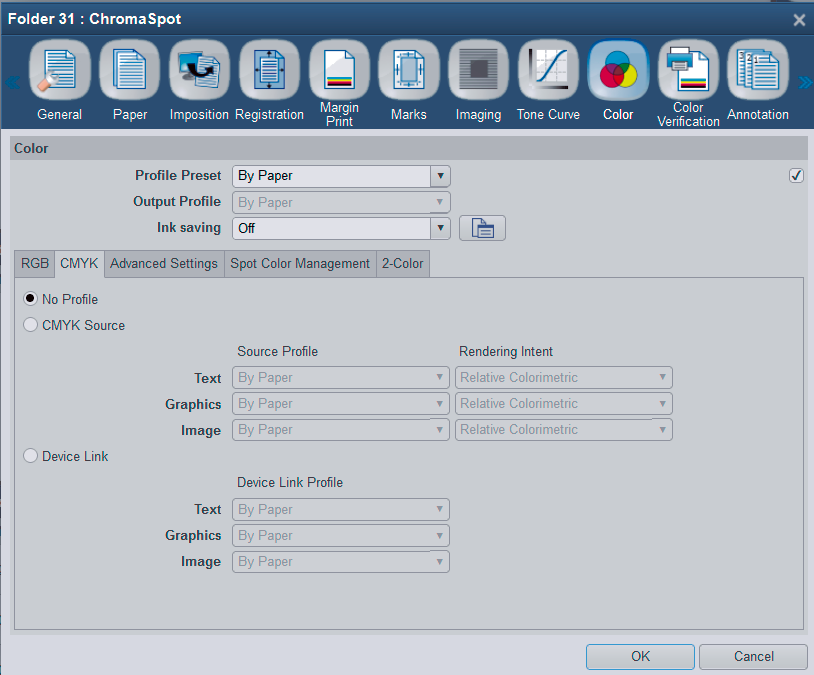

The second tab is focused on CMYK.

The user has to understand the consequences of the selected setting.

This is a general overview of the usage of LUTs. Additional documents are focused on various aspects.

Please consult the following documents:

1. Paper Setup

2. ChromaChecker Color Match Scan (CC Capture).

3. Applying LUTs

4. Printing Fanbooks

5. Understanding Postproduction Finishing

Related Topics

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.