Support

- Intro

- Inspectors

- Print Industry

- Brand & Print Buyers

- Color Manufacturing

- Design & Photography

- CC Products

- Tests & Audits

- Trainings

-

T-42 — Instrument Inspector Target

-

Introduction to QuickChecker Interface

- Project Inspector

-

Print Inspector

- Trial - Getting Started — Benchmark Self-Audit (CC-84)

- QuickStart with existing measurement data

- DIY: Benchmarking Printer

- Basic PI features

- Understanding Print Inspector

- Quick Start Guide - Printer G7 Check and GRACoL Targeting

- Practical tips for Print Inspector

- Advanced PI tools

- Print Inspector Expert mode

- Print Conditions

- Ink Zones

- OK Sheet

- Baselining

- CC Control Strips and Charts

- SCCA Calculator

- G7 Calibration Closed Loop

- Virtual Control Strip (VCS) Tasks

- Instrument Inspector

-

Color Inspector

- QuickStart — Create Color Palette

- QuickStart — Track Color Sample

- Create Color Palette

- Collections

- Tracking Brand Colors

- Palette vs. Library

- Sample: Corporate Spots Library

- Track Color Sample

- Export to Adobe Swatch Library (.ASE or .ACB)

- Exchange Color Libraries with X-Rite eXact

- Export CxF from website interface

- CATZper to ChromaChecker transition

- Color Variator

- Create a Library on the website

- Color Inconsistency Index for Custom Lighting

- Snowflake - Spot Color Tolerance

- Grid - Spot Color Matching

- Evaluate Color Library at Custom Lighting

- Color Inspector Database Architecture

- PDF Color Spaces

- Suppliers Inspector

- Lighting Inspector

- Accountability Inspector

- G7® Curve Inspector

- Substrate Inspector

-

CC Display Inspector

- Capture Inspector

-

Performance Inspector

- Environmental Inspector

- ICC Profile Inspector

- Fountain Inspector

- Plate Inspector

- NIP Inspector

-

CC Inspectors

Ink Zones

To control the uniformity of an offset press, the operator interface can display densities across the sheet. if the data is contained in the file. A variety of file formats are supported e.g.: Heidelberg CGATS file (Image Control), X-Rite Intellitrax SVF files, KBA XML files or Techkon Expresso / Spectra Drive / CGATS files, or presses that are using the X-Rite Ink Key software, MeasureColor, Print Measure, Rutherford Closed-loop, and Alwan Print Standardizer and Verifier.

ChromaChecker recognizes the ink zone information from within the file and will activate the Ink Zone Reporting within the operator interface. ChromaChecker Uploader is used to make a copy of the measurement data and immediately and securely upload the information via a secure SOAP protocol. to the Chromachecker interface and real-time feedback to the operator.

The big advantage of the ChromaChecker system is that report combines Ink GPS information and at the same time, the SCCA formula recalculates AIMs dynamically.

Regular website InkZone report consists of two sections:

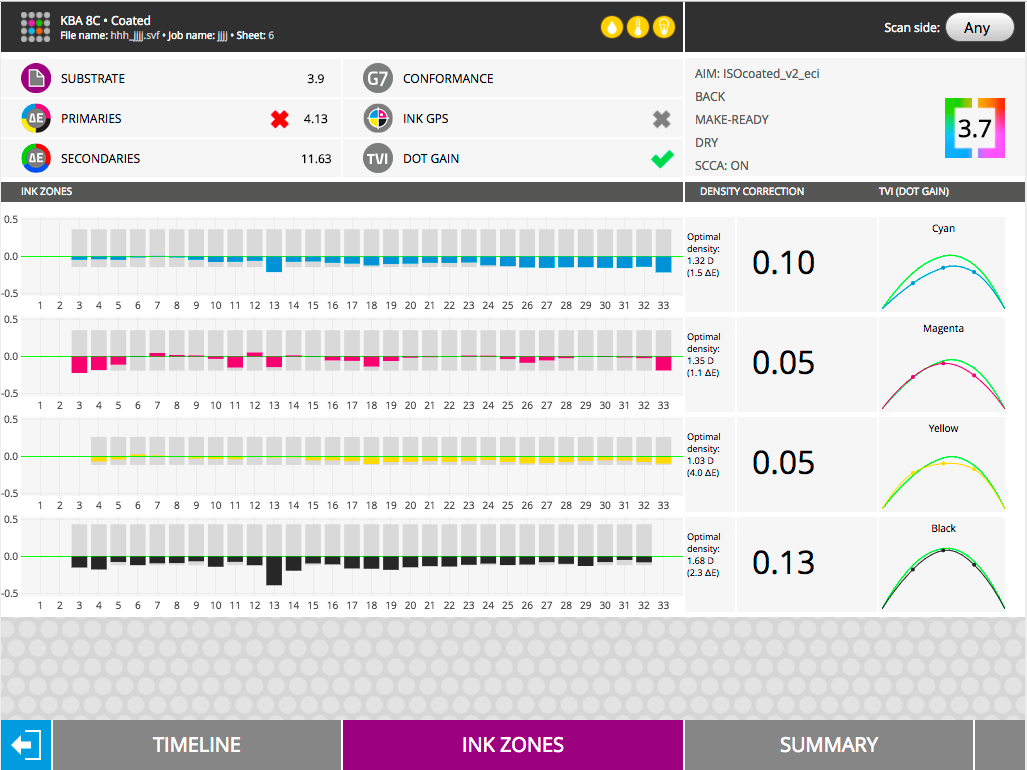

1. Density

Grey rectangles and green lines show ink GPS information - the optimal range where values are in the tolerance.

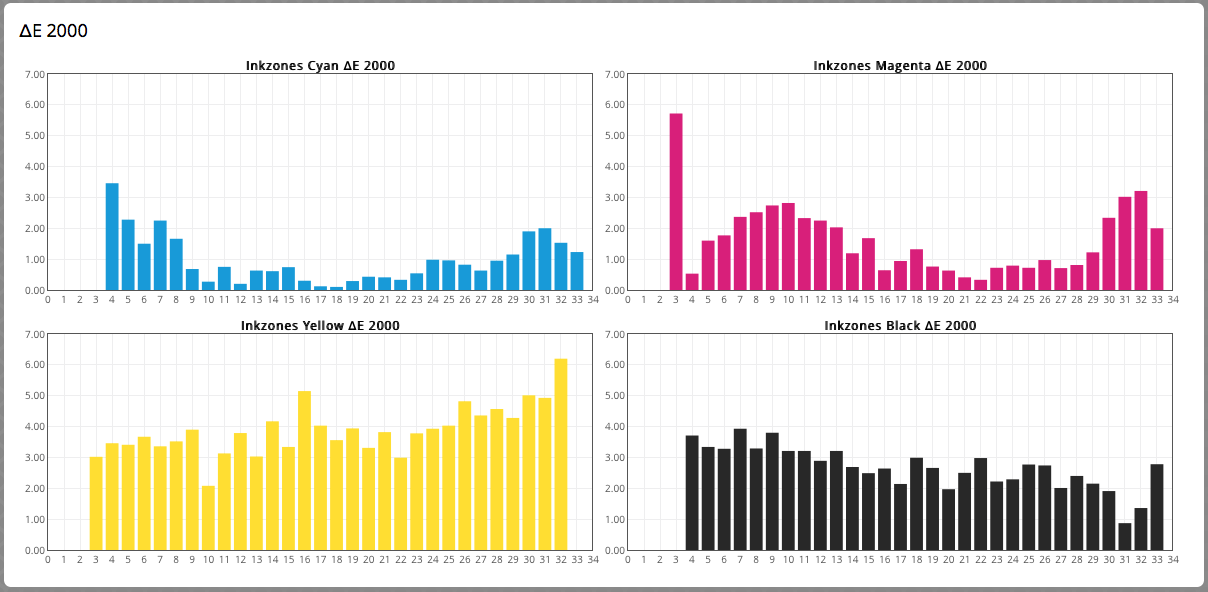

2. ∆E 2000

An example of an Ink Zone report on the Operator's interface:

Grey rectangles and green lines show ink GPS information - the optimal range where values are in the tolerance.

Additionally, Operator's interface displays useful information like TVI (dot gain) curves, global density correction, variation warnings dataloggers status, and general scoring.

Operator's Interface is a website that can be reduced to 1024 x 768 resolution - most the tablets can be used for this purpose (a full-screen web browser should be installed)

Contact ChromaChecker Support

Additional information and Support Form is available for logged users.